Feeding system driving coupling device of molding machine

A technology of driving coupling device and feeding system, which is applied in the field of rubber tire machinery, can solve the problems affecting the tire making efficiency, the misalignment of the cord, and the quality of the green tire, so as to achieve high production efficiency, good elastic effect, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

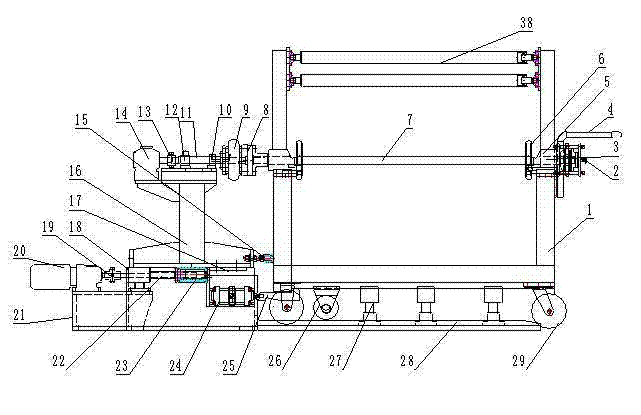

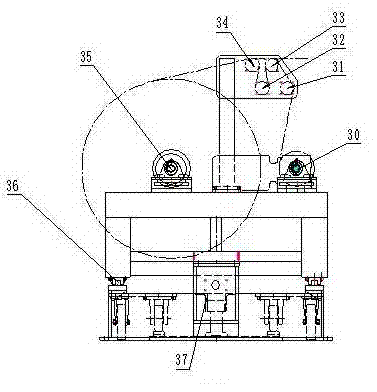

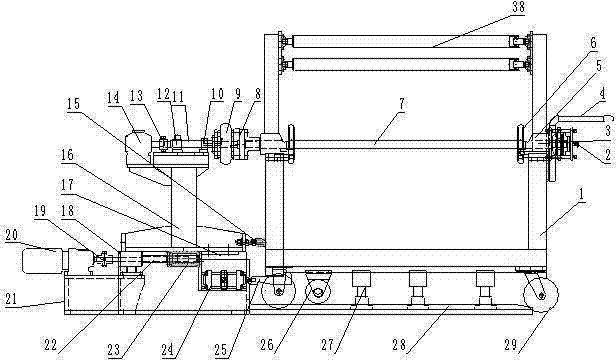

[0019] The driving connection device of the molding machine feeding system of the present invention is realized in this way: as figure 1 , figure 2 As shown: the handle (4) pushes the feeding trolley, the small wheel (26) on the feeding trolley moves to the bottom of the feeding rack along the guide rail (28), the hook (25) connects with the edge of the trolley frame, and the connecting key (8 ) A connection key (8) and B are connected, when the material on the feeding trolley deviates, the information is fed back to the motor (20) through the encoder, and the motor (20) rotates to drive the connecting block on the movable frame (16) (17), the movable frame (16) moves along the guide rail (36), and the hook (25) pulls the trolley, thereby adjusting the position of the material.

[0020] The material is divided into two paths through the export mechanism (38), one path of the ply layer enters the roller table of the feeding rack through the peeling roller (33) for lamination,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com