Harvester for harvesting straw covered winter potatoes

A potato and harvester technology, applied in excavator harvesters, harvesters, applications, etc., can solve the problems of straw and separation mechanism entanglement, blocking separation effect, affecting potato mechanized harvesting operations, etc., and achieve broad market application and promotion Foreground, good separation effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

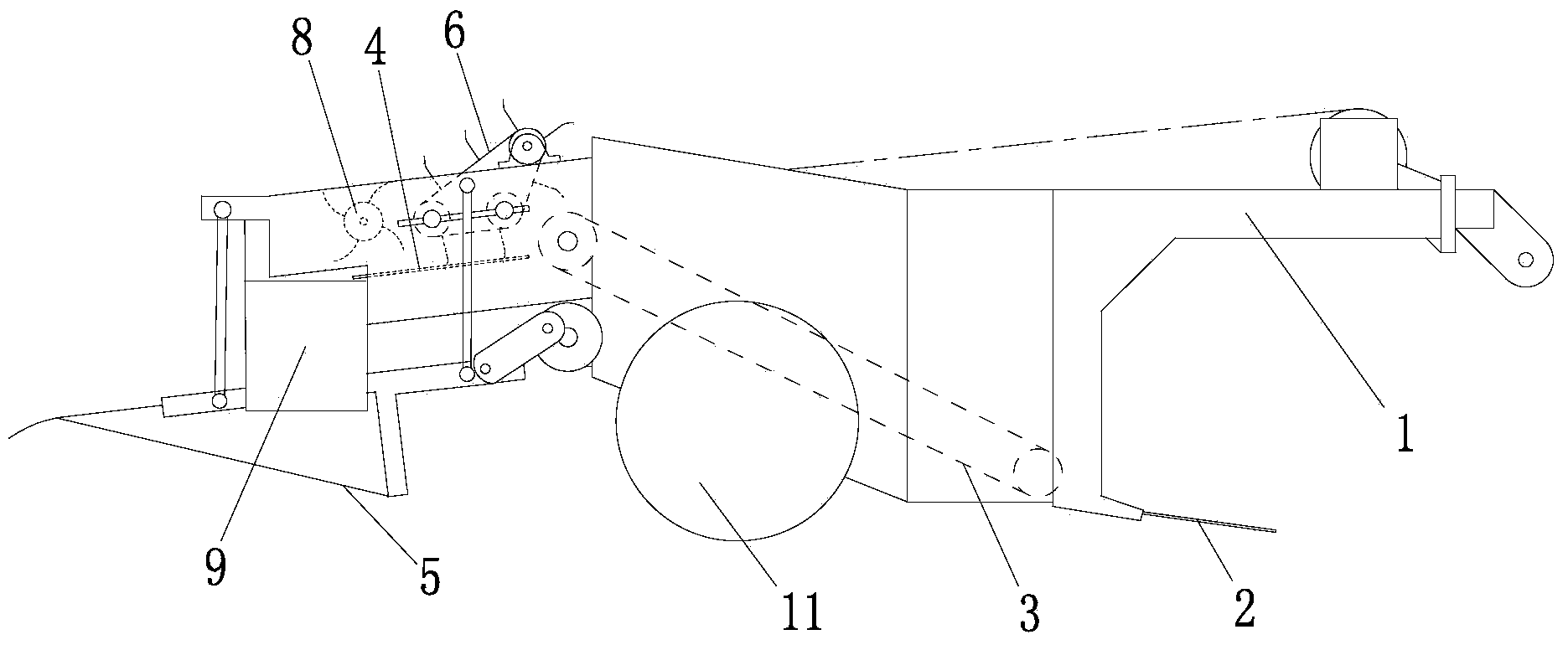

[0028] Such as figure 1 Shown, a kind of harvester that is used for harvesting grass-covered winter-planted potatoes includes a frame 1 that is pulled by a tractor and has road wheels 11, a digging shovel 2 that is arranged on the frame 1, a power assembly that provides power, and The transmission mechanism 3 that is arranged on the rear end of the excavating shovel 2, the transmission mechanism 3 is specifically a grid chain transmission mechanism, the output end of the transmission mechanism 3 is provided with a grass-potato separating screen 4, and the grass-potato separating screen 4 is provided with a The grass-discharging assembly is provided with a potato-soil separating mechanism 5 below the grass-potato separating screen 4 .

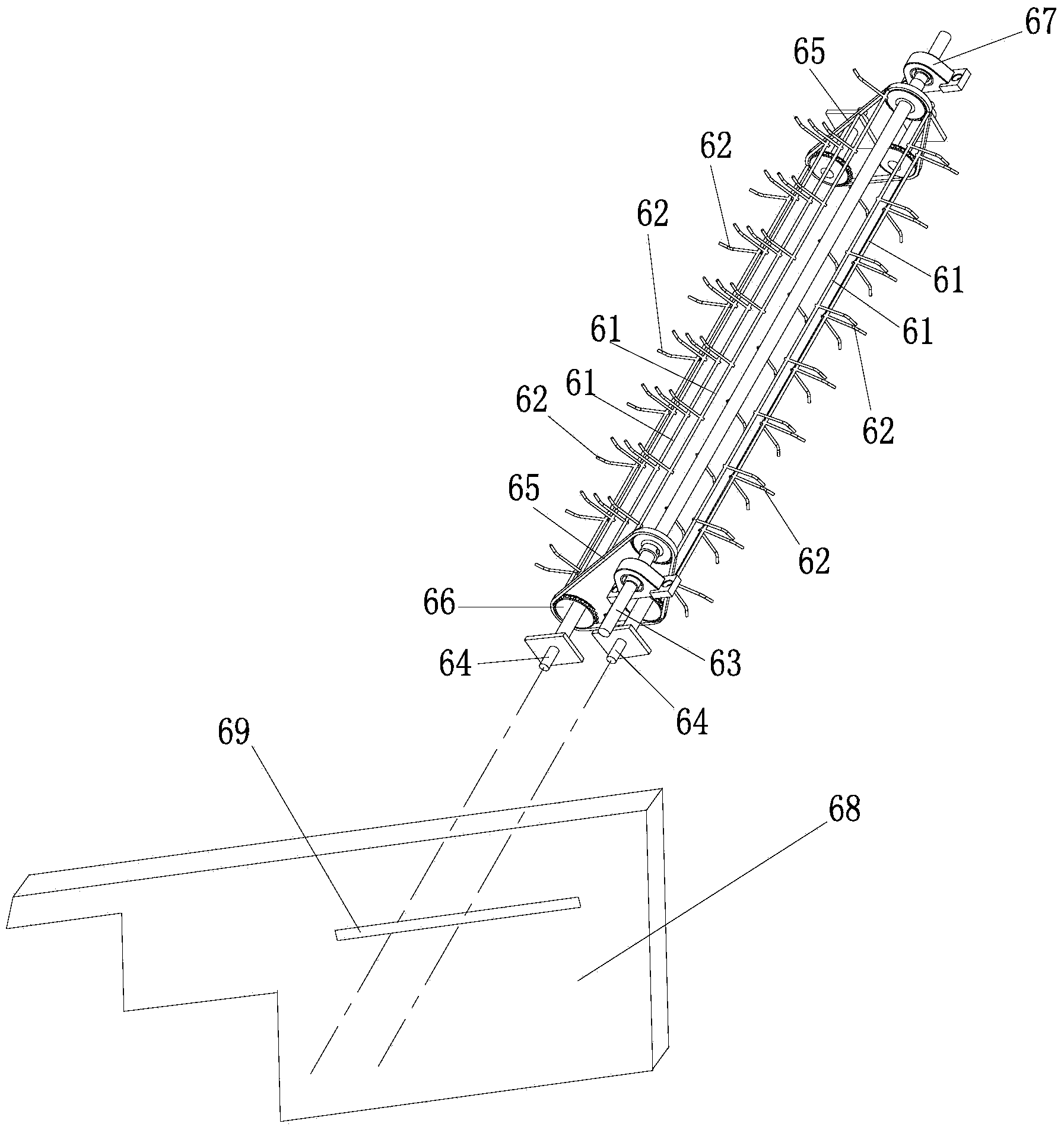

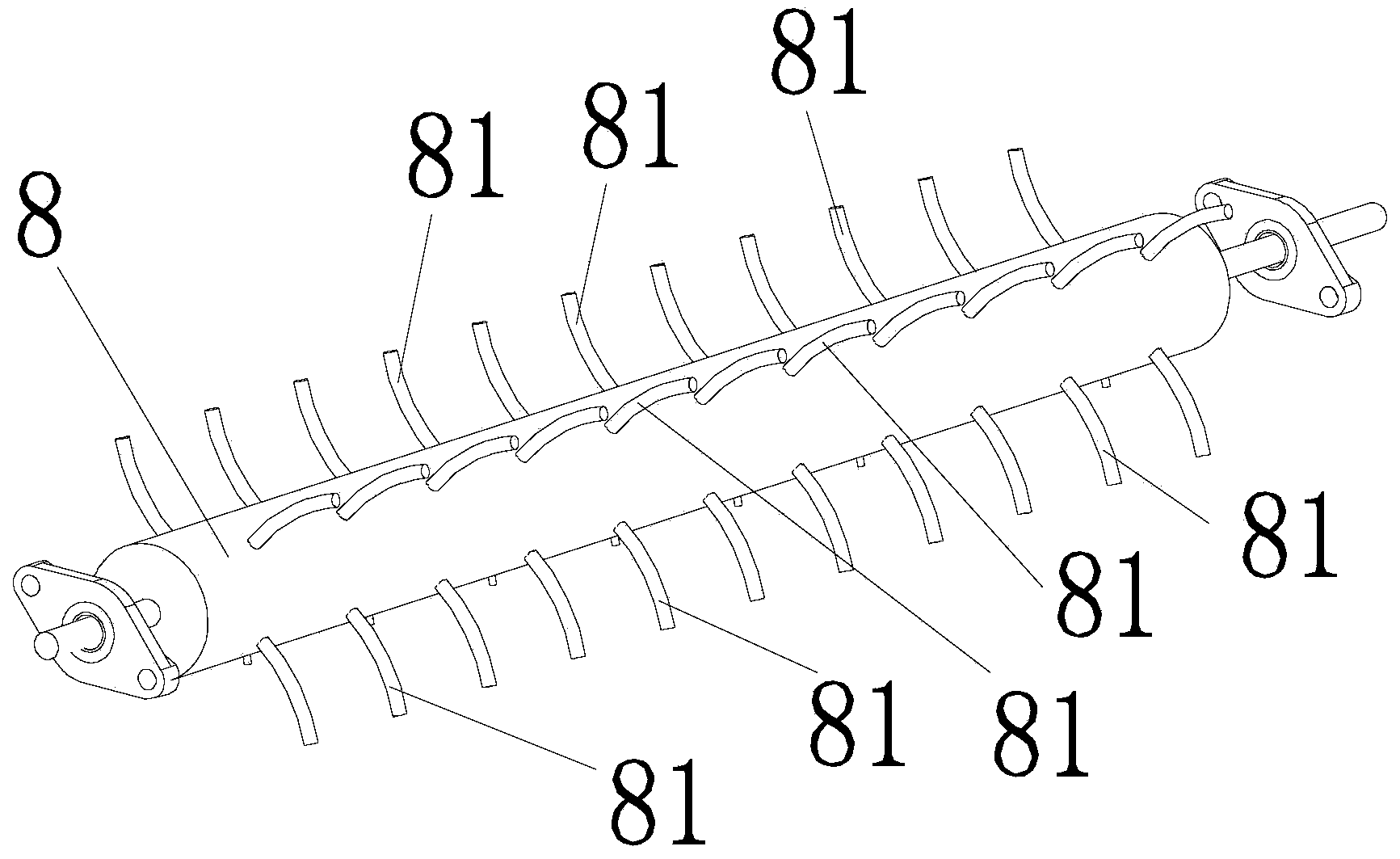

[0029] Such as figure 1 and 2 As shown, the grass discharge assembly includes a conveying mechanism 6 and a grass falling mechanism 7, and the conveying mechanism 6 includes a comb-toothed rod 61 that circulates above the grass and potato sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com