Manufacturing method for bubble water

A bubble water, a certain amount of technology, applied in the field of production of bubble water solution, can solve the problems of using a lot of materials and complicated production methods, and achieve good results and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

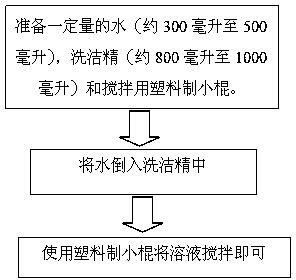

[0019] Such as figure 1 Shown is a method for making bubble water, including water, detergent and a stirring tool. The user first adds a certain amount of water, about 500 milliliters, into the detergent, and the detergent is about 1000 milliliters. Then use a stirring tool to stir the mixture evenly to complete the production of bubble water. The stirring tool can be selected such as a small stick made of plastic.

[0020] The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the patent scope of the present invention. Therefore, all equivalent structural changes made by using the description and illustrations of the present invention are included in the protection scope of the present invention. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com