Etching agent for inspecting S31042 and T91 or T92 dissimilar steel welding joint and preparation method of etching agent

A technology for welding joints and etchants, which is applied in the field of etchant preparation, can solve the problems of difficulty in mastering the etching speed and degree of etching, restricting the observation, analysis and photography of samples, and affecting the quality and efficiency of detection, so as to improve the Detection quality and detection efficiency, excellent and reliable detection methods, mild and easy-to-control etching process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Prepare etchant as follows:

[0031] (1) Measure 100g of distilled water and place it in a beaker, add 8g (in C 2 h 2 o 4 ﹒ 2H 2 O meter) oxalic acid (analytical pure, C 2 h 2 o 4 ﹒ 2H 2 O content 99.5%), stir after oxalic acid is completely dissolved, then add 50g (with H 3 PO 4 Meter) phosphoric acid (analytical pure, H 3 PO 4 Content 85%), continue to stir evenly, make etchant A;

[0032] (2) Measure 100g of distilled water and place it in a beaker, add 30g (in terms of NaCl) sodium chloride (analytically pure, NaCl content 99.5%), stir until the sodium chloride is completely dissolved, then add 100g (in terms of H 3 PO 4 Meter) phosphoric acid (analytical pure, H 3 PO 4 Content 85%), continue to stir evenly, make etchant B;

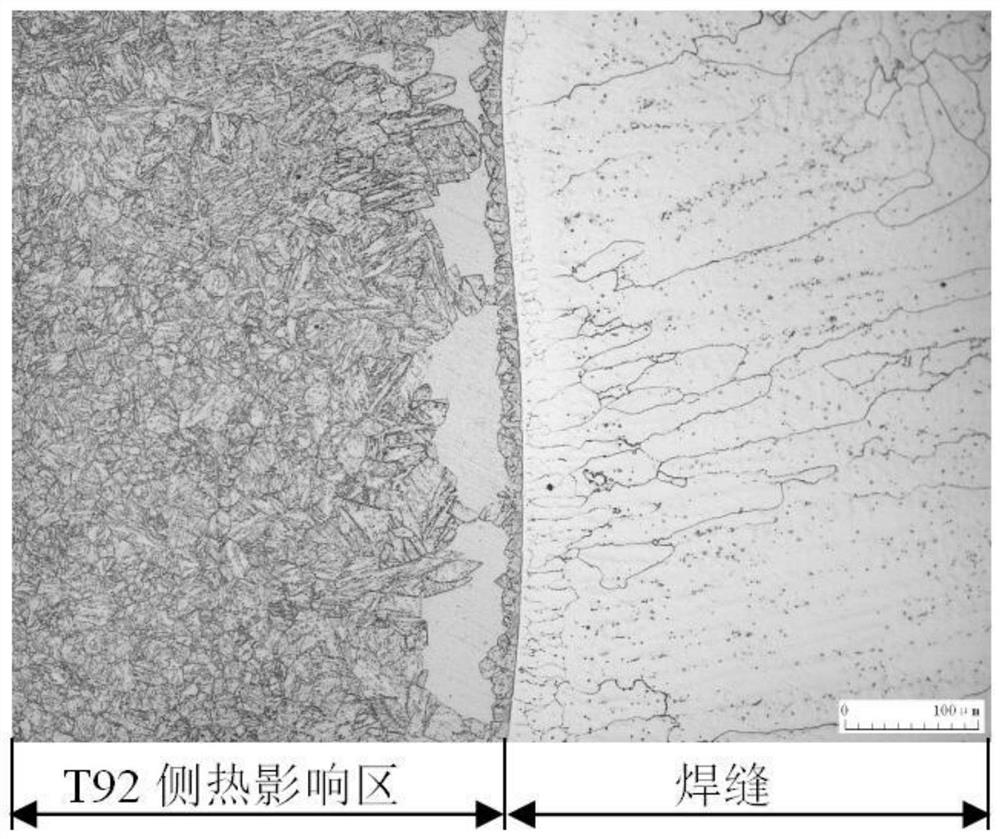

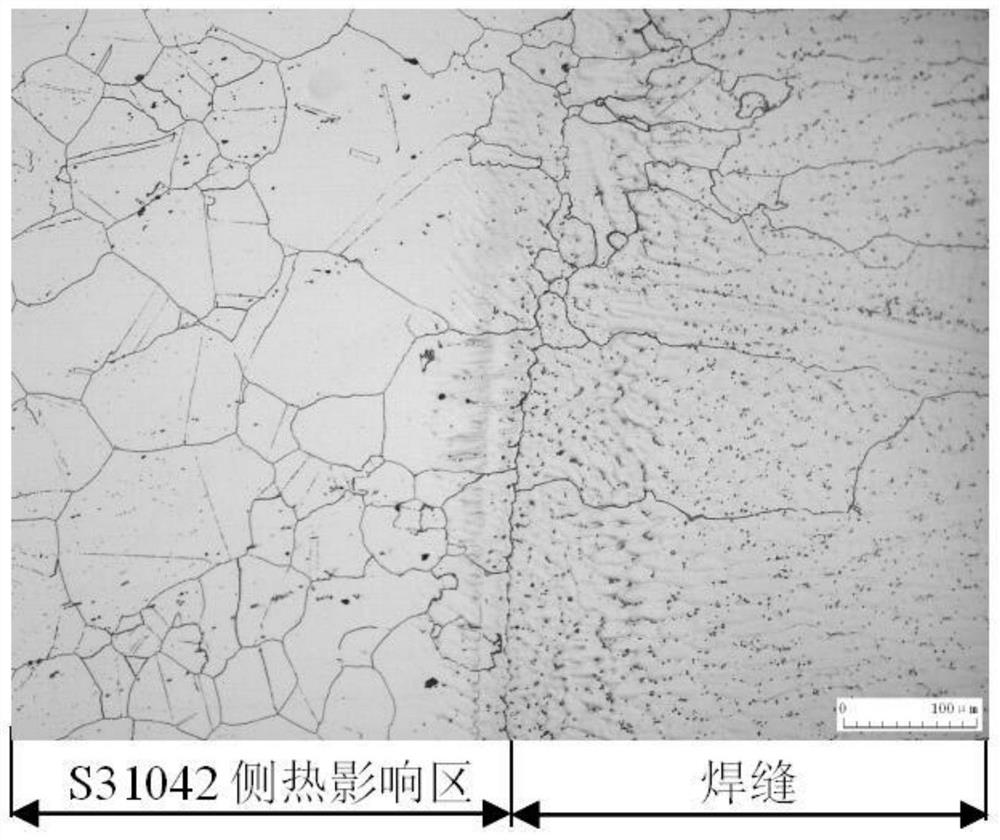

[0033] Carry out metallographic inspection of welded joints of S31042 and T92 dissimilar steels according to the following method:

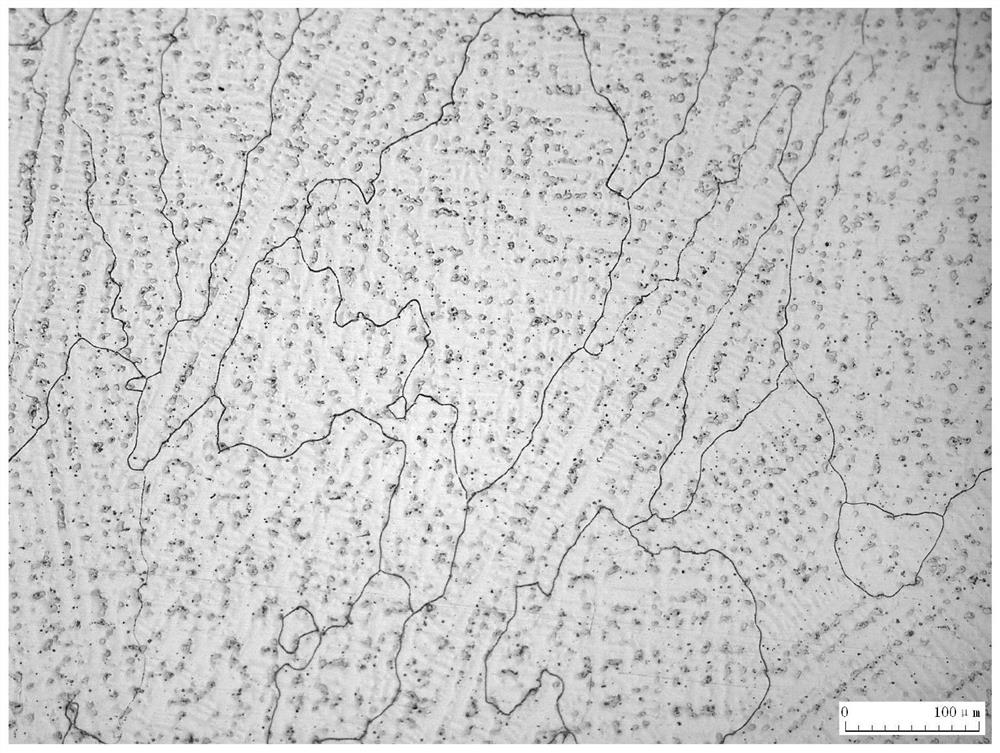

[0034] (3) Immerse the ground and polished welded joint sample in etchant A for electrolytic ...

Embodiment 2

[0038] Prepare etchant as follows:

[0039] (1) Measure 90g of distilled water and place it in a beaker, add 6g (in C 2 h 2 o 4 ﹒ 2H 2 O meter) oxalic acid (analytical pure, C 2 h 2 o 4 ﹒ 2H 2 O content 99.5%), stir after oxalic acid is completely dissolved, then add 42g (with H 3 PO 4 Meter) phosphoric acid (analytical pure, H 3 PO 4 Content 85%), continue to stir evenly, make etchant A;

[0040] (2) Measure 90g of distilled water and place it in a beaker, add 25g (in terms of NaCl) sodium chloride (analytically pure, NaCl content 99.5%), stir and wait for the complete dissolution of sodium chloride, then add 85g (in terms of H 3 PO 4 Meter) phosphoric acid (analytical pure, H 3 PO 4 Content 85%), continue to stir evenly, make etchant B;

[0041] Conduct metallographic inspection of welded joints of S31042 and T91 dissimilar steels according to the following method:

[0042] (3) Immerse the ground and polished welded joint sample in etchant A for electrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com