Chromic oxide catalyst for alkali liquor surface treatment as well as preparation method and application thereof

A surface treatment, chromium oxide technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. The effect of NO release performance, good application prospect and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

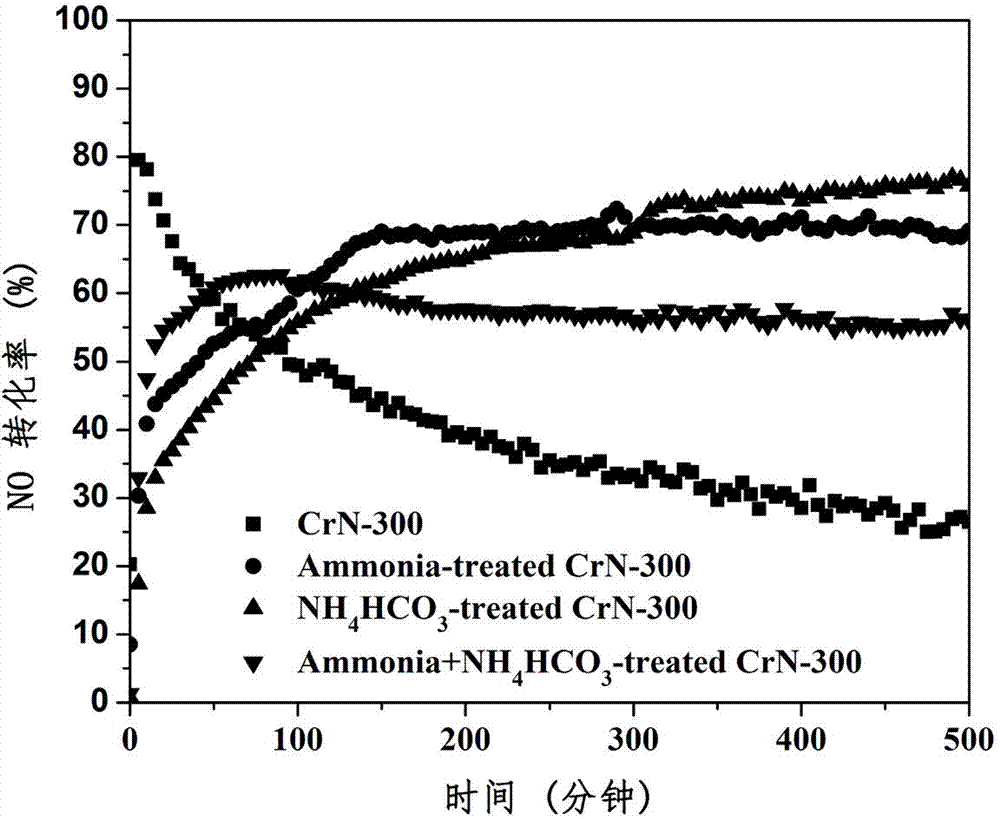

[0024] Take by weighing chromium nitrate 10.0g and directly put into the muffle furnace for 300 o C was calcined for 4h to obtain chromium oxide powder.

[0025] Alkali surface treatment chromium oxide catalyst preparation:

[0026] Using excessive impregnation, soak chromium oxide powder in ammonia solution, the concentration of ammonia water is 25%, after soaking for 12 hours, put it into 100 o After drying in C oven for 12 hours, put it into the muffle furnace at 300 o C was calcined for 4 hours to obtain the chromium oxide catalyst for alkali solution surface treatment.

[0027] Weigh 0.5g of the catalyst obtained above and start feeding reaction gas at room temperature for activity test. The gas composition is 15 ppm NO, the rest is air, and the total flow rate is ≥720 ml / min (STP).

Embodiment 2

[0029] Compared with Example 1, the difference is that the lye is an ammonium bicarbonate solution, and the amount of other materials and operating conditions are the same as in Example 1.

Embodiment 3

[0031] Compared with Example 1, the difference is that the lye is a mixed solution of ammonium bicarbonate and ammoniacal liquor, and the amount of other materials and operating conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com