Magnetic separation fluid iron removal method and device

A fluid and magnetic separation technology, which can be used in cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc. It can solve the problems of weakening magnetic attraction, reducing the magnetic force of protruding parts, and difficulty in cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

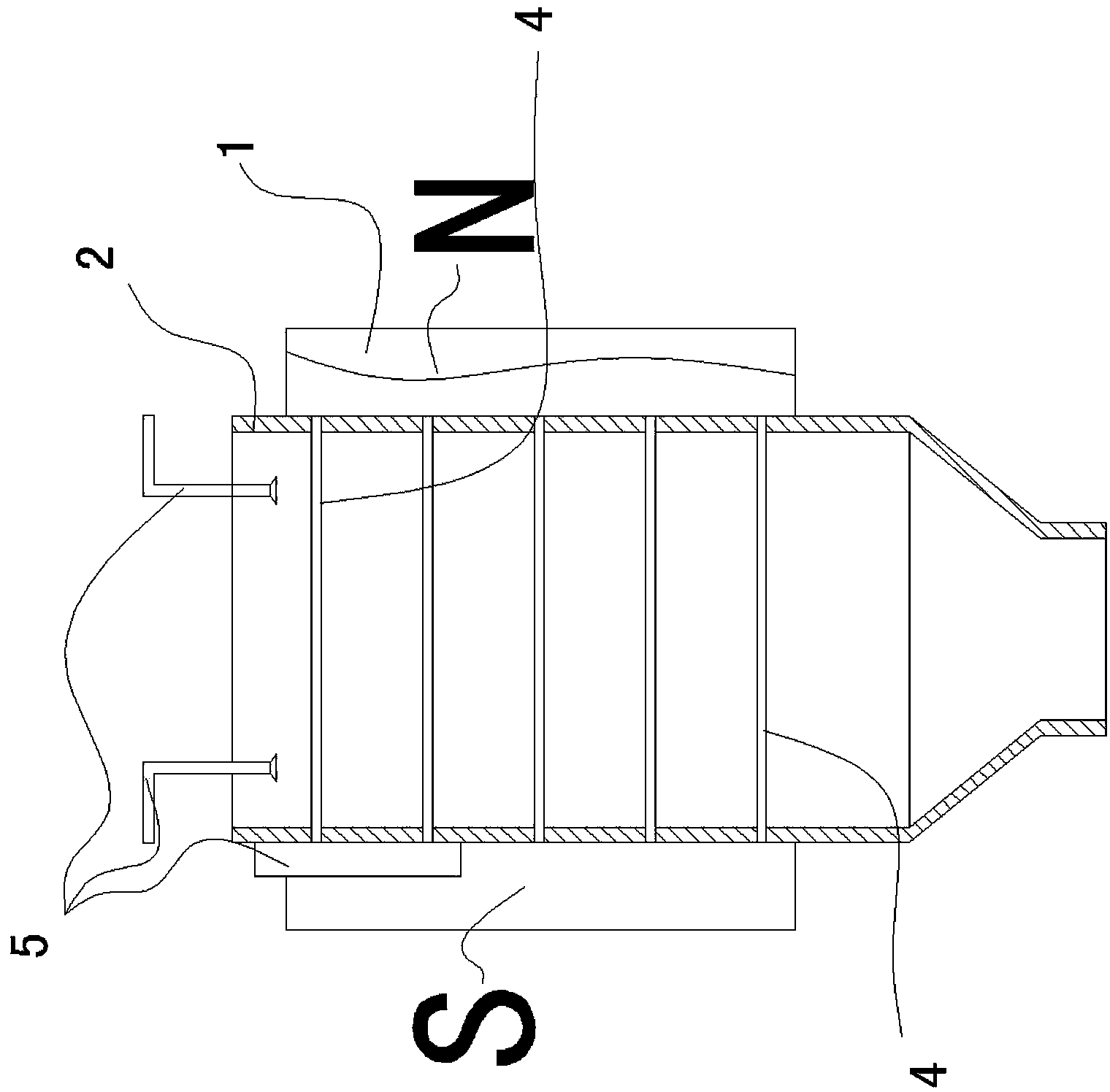

[0022] Embodiment 1: as figure 1 As shown, the magnetic separation type fluid iron removal device of the present invention is realized in this way, including an electromagnetic or permanent magnetic field 1, a fluid channel 2 made of non-magnetic material, and several layers arranged in the fluid channel 2 by several soft magnetic The soft magnetic medium layer 4 and the soft magnetic medium cleaning mechanism 5 formed by the medium 3 are special in that the symmetrical parts on both sides of the cross section of each soft magnetic medium 3 are protruding parts 6, and the two protruding parts 6 are outermost The distance A between the ends is greater than the distance between the two ends of other parts of the soft magnetic medium cross section, two adjacent soft magnetic mediums 3 in each layer are arranged in parallel, and the soft magnetic medium 3 is freely rotatable and set in the fluid channel 2.

Embodiment 2

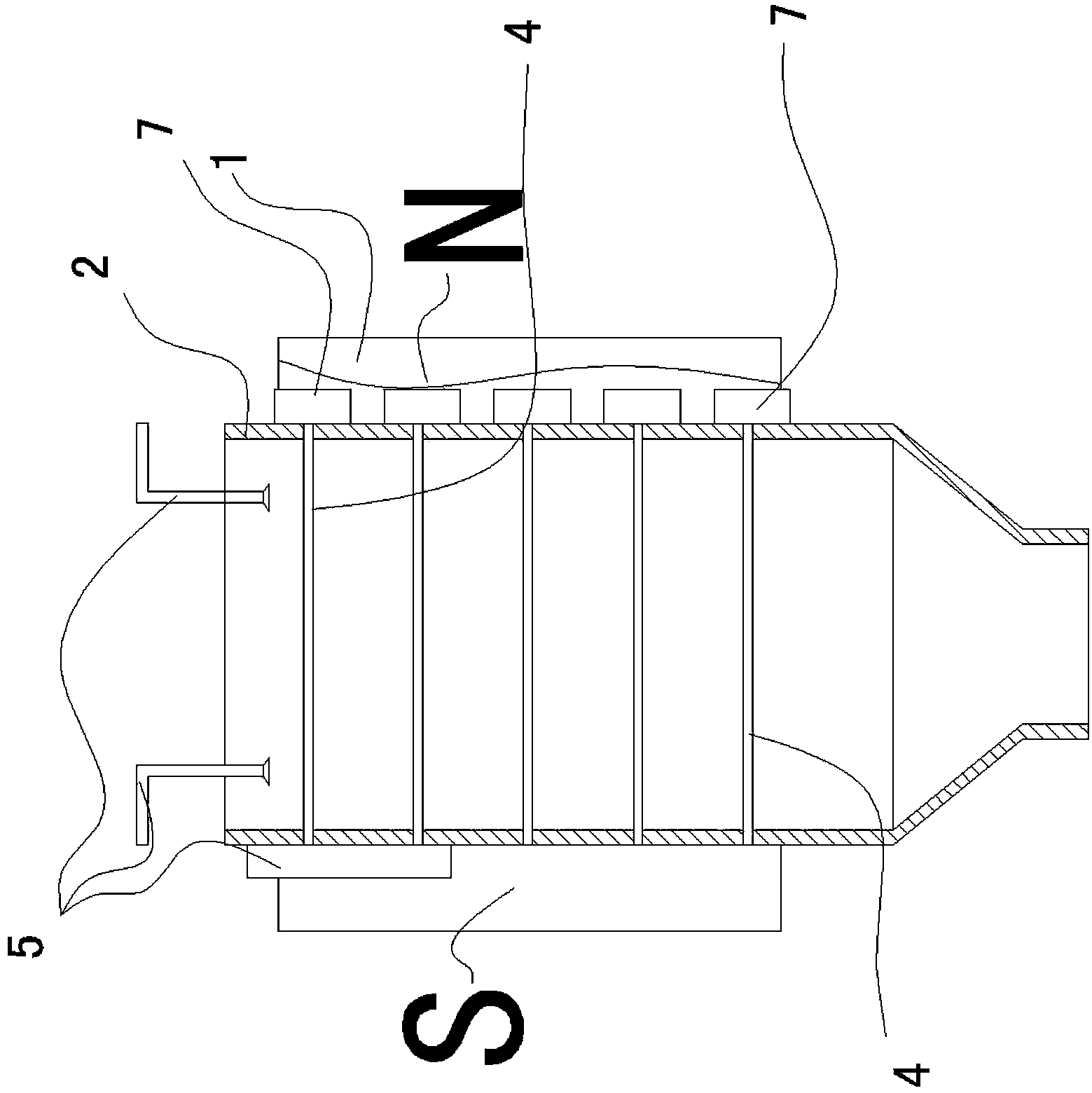

[0023] Embodiment 2: as figure 2 As shown, the present embodiment is based on the embodiment 1, and a rotation drive mechanism 7 for driving each soft magnetic medium 3 to rotate is provided on the outside of the fluid channel 2 .

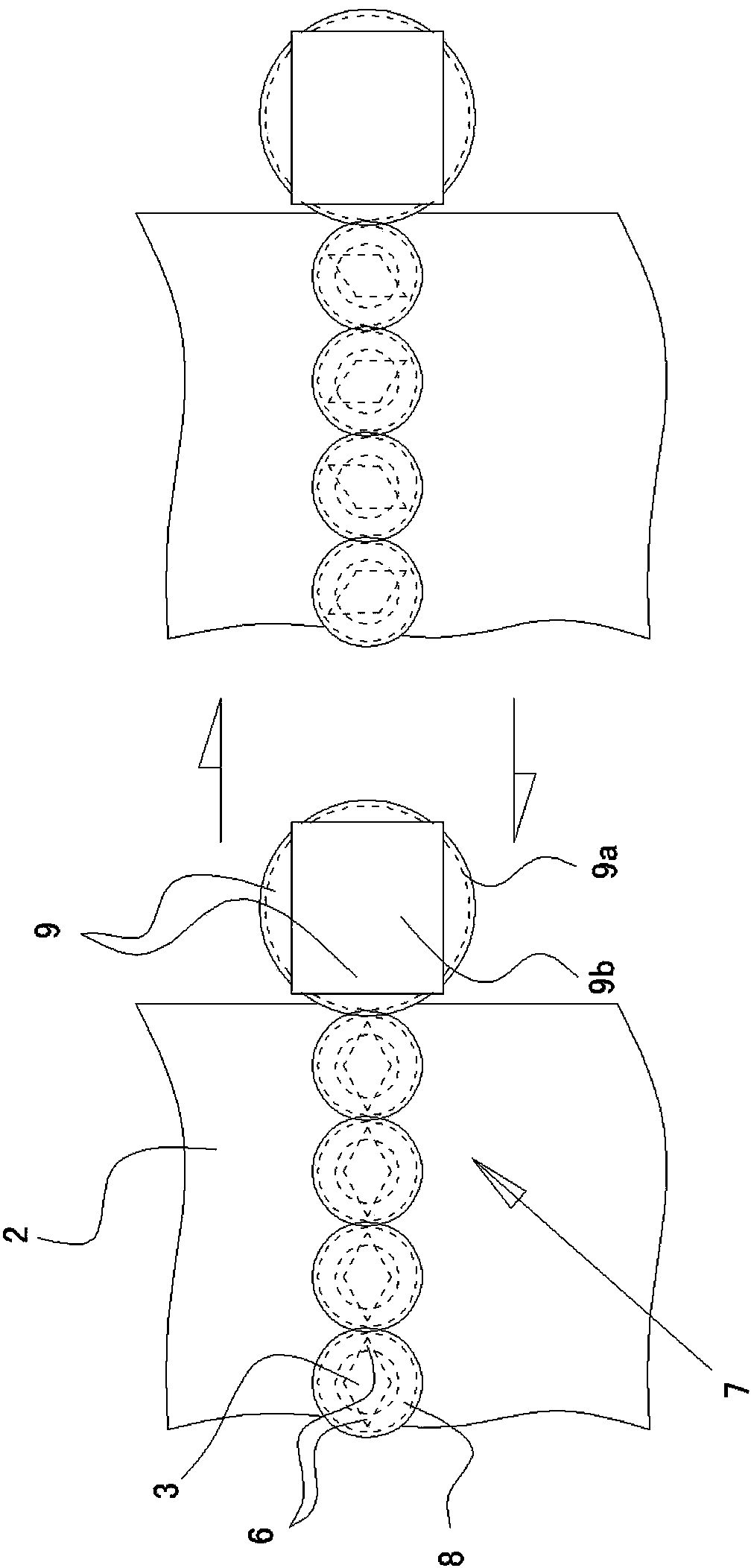

[0024] Such as image 3 As shown, embodiment 1 of rotation driving mechanism 7 includes a gear 8 arranged at the end of each soft magnetic medium 3, a driving mechanism 9 for driving the gear (comprising a driving gear 9a meshing with the gear 8, an electric power 9b for driving the driving gear 9a) ), the gears on each layer of soft magnetic medium 3 mesh with each other.

[0025] Such as Figure 4 As shown, embodiment 2 of rotation drive mechanism 7 includes a swing rod 10 connected to each end of soft magnetic medium 3, a drive rod 11 that drives the swing rod 10 to swing, a drive mechanism 12 that drives the drive rod 11 (comprising cylinder 12a, driven by The connecting rod 12b driven by the piston rod of the cylinder 12a, the connecting r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com