Automatic hang tag conveying, stringing and knotting device and method

A technology of automatic conveying and knotting device, applied in the directions of transportation and packaging, packaging, paper product packaging, etc., can solve the problems of low production efficiency, manual manual threading, etc., and achieve high production efficiency, low preparation cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

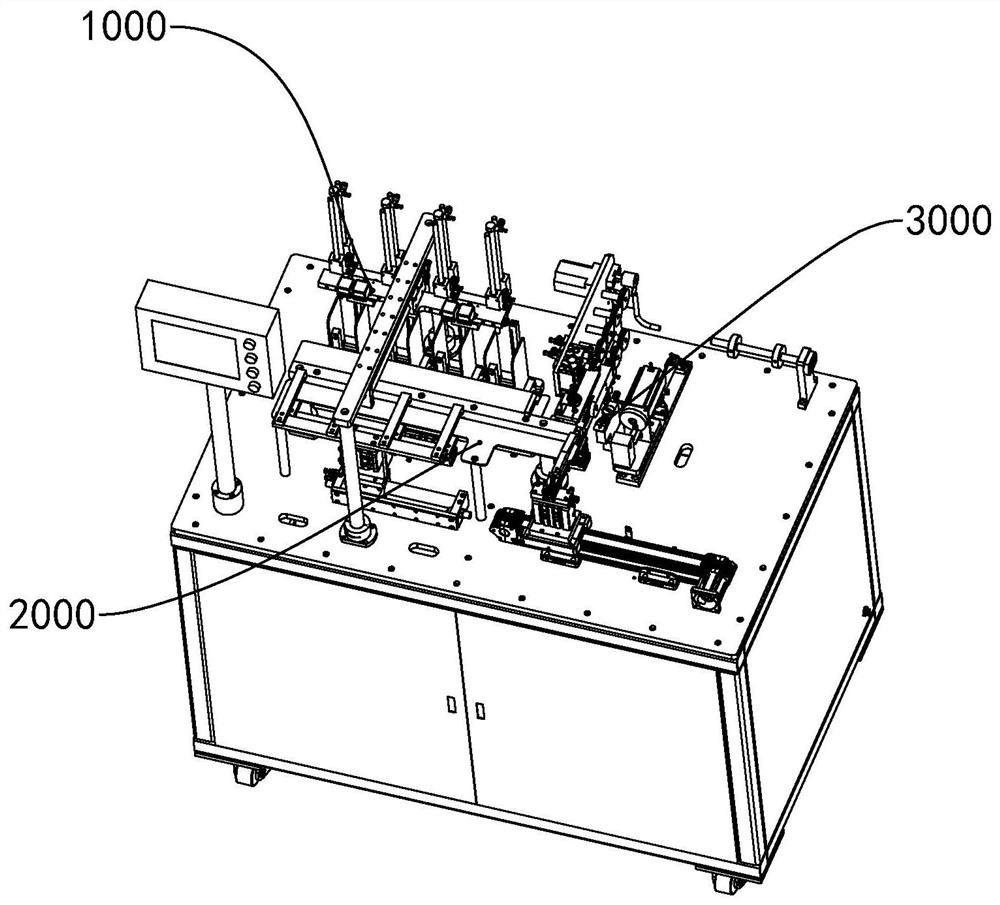

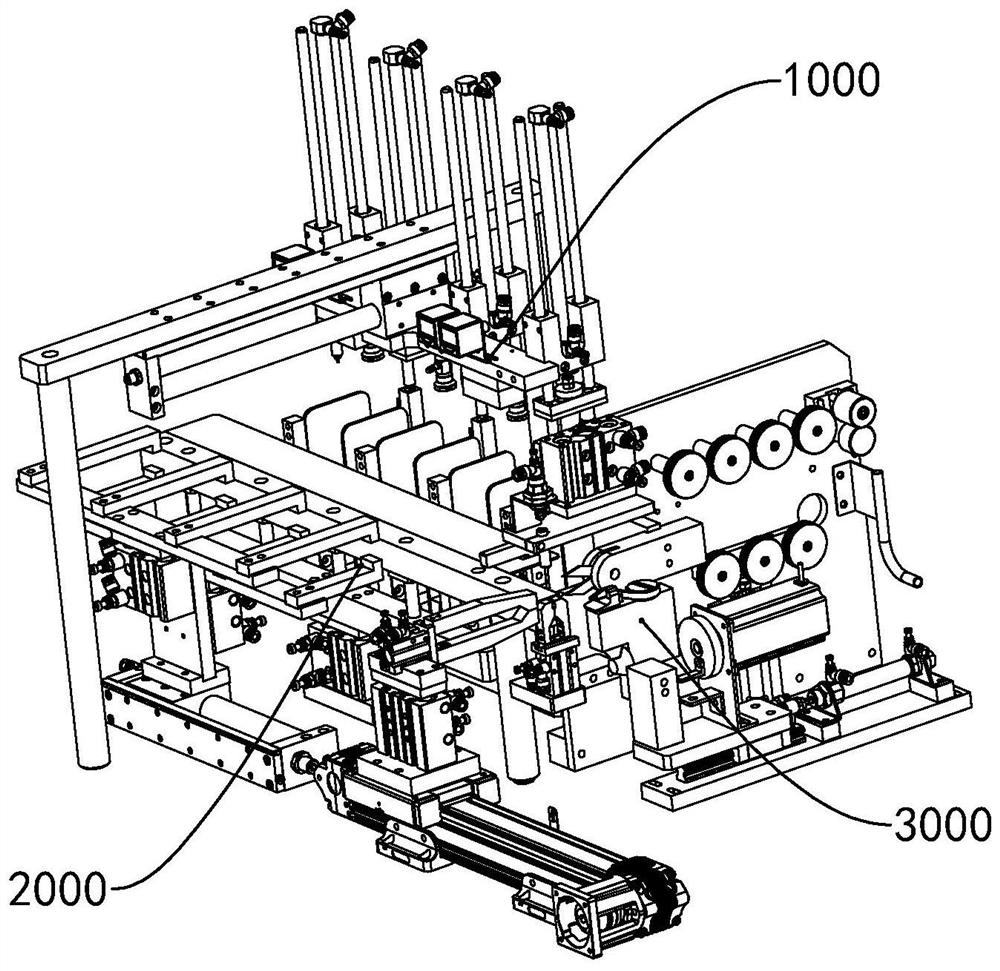

[0035] Such as Figures 1 to 2 As shown, the hanging tag automatic conveying and stacking rope knotting device of this embodiment includes a hanging tag conveying device 1000 , a hanging tag translation device 2000 and a hanging tag threading and knotting device 3000 .

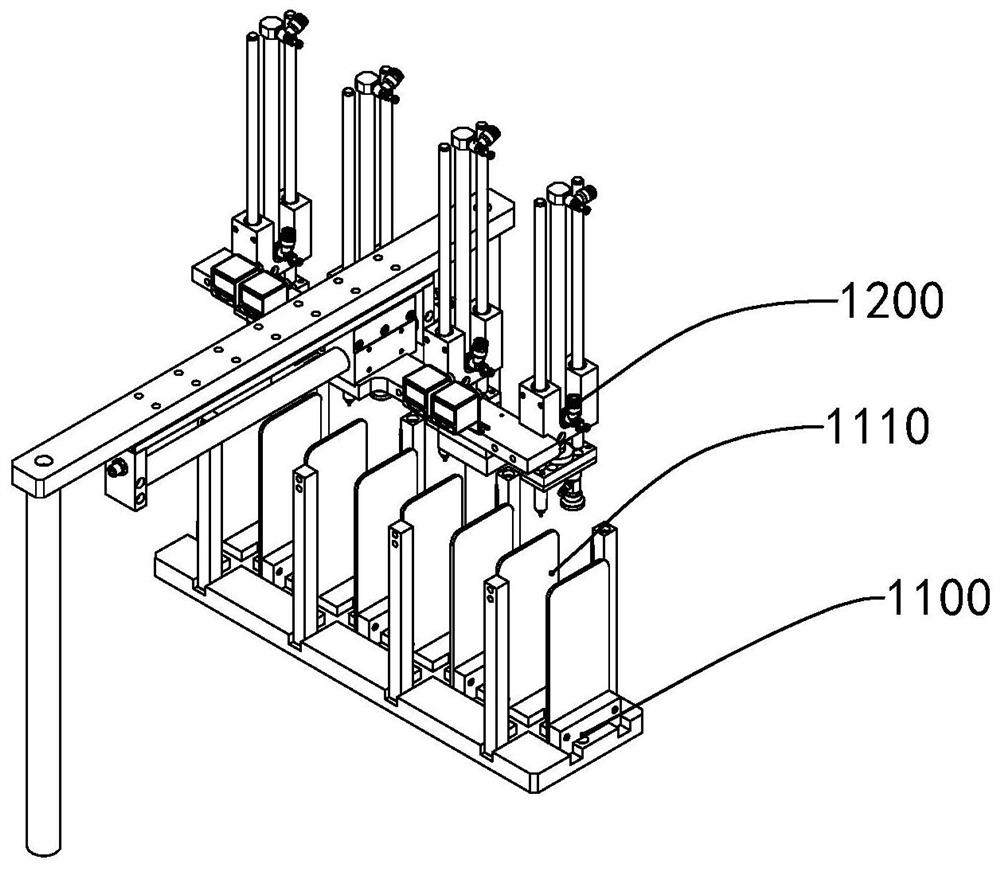

[0036] Such as Figures 3 to 7 As shown, the tag conveying device 1000 includes a chute assembly 1100 and a pick-and-place mechanism 1200 . Wherein, the material trough assembly 1100 includes a plurality of placing troughs 1110, and the placing troughs 1110 are used for stacking and placing a plurality of hanging tags laid flat.

[0037] The pick-and-place mechanism 1200 includes a mounting block 1210 , a sliding seat 1220 , a first cylinder 1230 , a second cylinder 1240 , a vacuum chuck 1250 and a laser sensor 1260 . The mounting block 1210 straddles the placement slot 1110, the sliding seat 1220 is movably connected directly or indirectly to the mounting block 1210, and the first cylinder 1230 is used to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com