Slurry demagnetizing device for battery production

A magnetic device and slurry technology, which is applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., to achieve the effect of easy disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

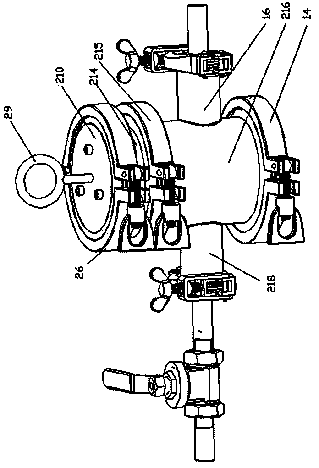

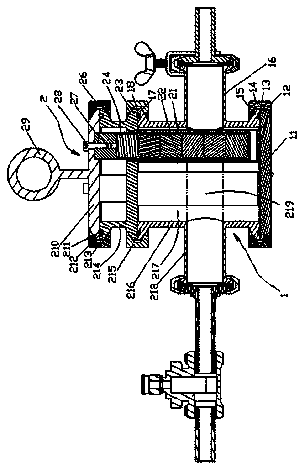

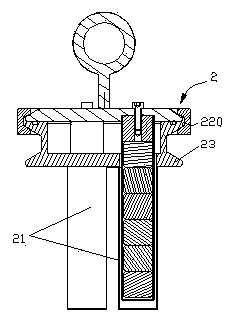

[0022] Such as Figure 1 to Figure 6 As shown, the present invention comprises: cylinder body 1, described cylinder body is made up of cylindrical shell 216, cylinder bottom 11, cylinder bottom hoop 14, slurry inlet pipe 16, slurry outlet pipe 218, described cylindrical The inside of the casing is provided with a cylindrical cavity 217, the bottom surface of the cylindrical casing is flat, that is, the opening surface of the bottom of the cylindrical casing is flat, the upper surface of the bottom 11 of the cylindrical casing is flat, and the bottom surface of the cylindrical casing is connected to the top of the bottom of the cylindrical casing. Surface sealing connection, this embodiment adopts sealing ring 13 sealing connection, and the connection between the cylindrical shell and the bottom of the cylinder is respectively provided with circular bottom hoops 15, 12 protruding outward, and the hoops of the bottom of the cylinder are connected with the bottom of the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com