Powder-accumulation-prevention type hopper for sensor molding extruding machine

A technology of sensors and extruders, which is applied in the hopper field of extruders in the sensor manufacturing industry, can solve the problems of powder agglomeration, inability to use, powder agglomeration, etc., to reduce the focus and prevent powder accumulation , the effect of preventing the accumulation of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

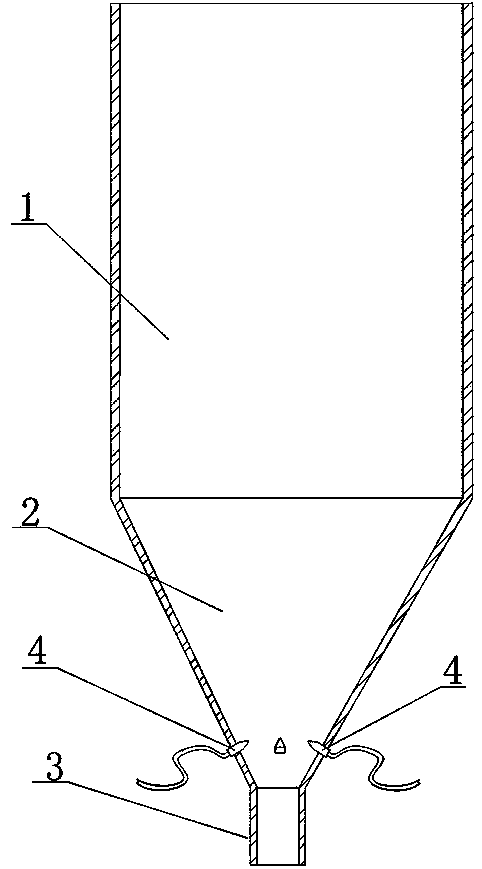

[0017] Such as figure 1 As shown, the sensor forming extruder hopper for preventing powder accumulation in the present invention includes a hopper body, and the hopper body is mainly composed of three parts: storage barrel 1, frustum body 2, and discharge barrel 3, and storage barrel 1 The whole is cylindrical, and its interior is a cavity structure. The frustum body 2 is a side wall connecting two circles. It has two end faces, both end faces are circular, and its center is located on the axis extension line of the storage barrel 1. Above, wherein the circular end surface with a larger radius is connected to the storage cylinder 1, and the circular end surface with a smaller radius is connected to the discharge cylinder 3. The discharge cylinder 3 is also a cylinder as a whole, and the storage cylinder 1 and the frustum body 2 , and the axis of the discharge cylinder 3 are all on the same straight line, the joints between the storage cylinder 1 and the frustum body 2, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com