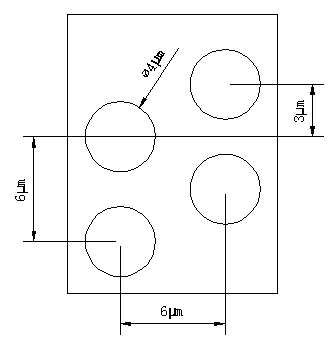

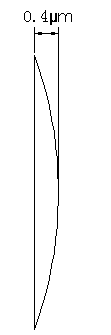

Dung beetle surface structure bionic gear

A surface structure and gear technology, which is applied in the field of bionic gears, can solve the problems of accelerated gear damage, material fragmentation, and inability to perform secondary quenching, etc., and achieve the effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Bionics is a new subject developed in recent years. Once proposed, it has developed rapidly and is widely used in medicine, military and other fields. Swiss engineer Georges Maestro invented Velcro from thorny seeds stuck to animal fur; hypodermic needles used in hospitals mimicked the teeth of rattlesnakes; Friction with the ground; the submarines that appeared during World War I used the principle of swim bladders to float and sink, and the sonar loaded on them also imitated the ultrasonic positioning principles of dolphins and bats.

[0043] The development of bionics and its successful application in different fields provide new ideas for solving the problem of mechanical wear. According to the traditional concept, it is generally believed that the smoother the surface of an object, the smaller the friction resistance it receives and the higher the wear resistance. Therefore, people are currently focusing on how to improve the machining accuracy to obtain a smoother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com