LED injection molding module

A technology of injection molding and electronic wires, which is applied in the field of new LED lighting, can solve the problems of long waiting time for curing, unstable LED modules, and low production efficiency, so as to improve production efficiency and yield rate, good waterproof and waterproof Dust effect, the effect of reducing the cost of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The LED injection molding module of the present invention will be described below in conjunction with the accompanying drawings and embodiments. The equivalent transformation or improvement of the LED module according to the principle, including the improvement of the shape, size, and material used of the LED module, as well as the addition, deletion and replacement of each part of the structure, to achieve the same function, all belong to this within the scope of invention protection.

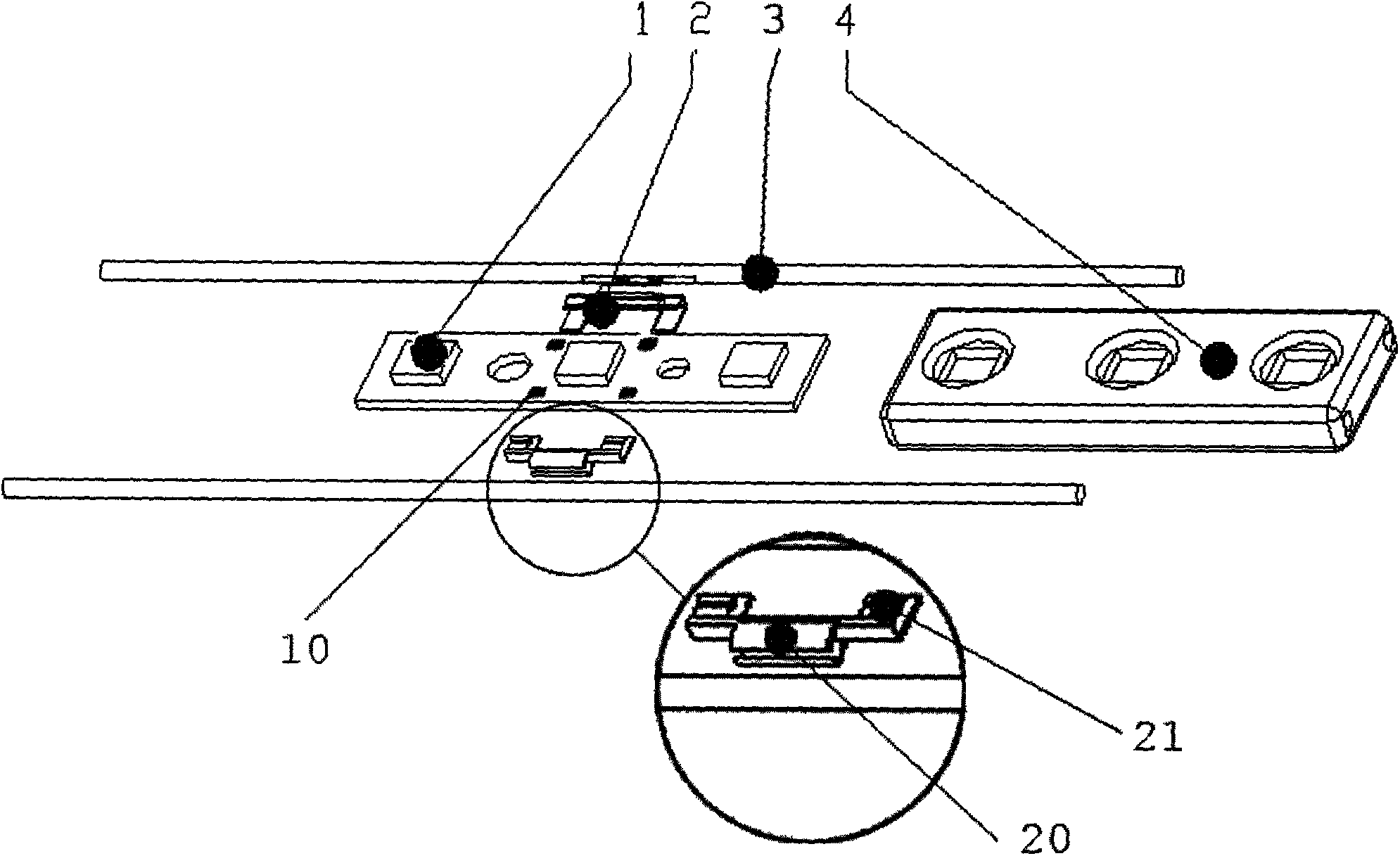

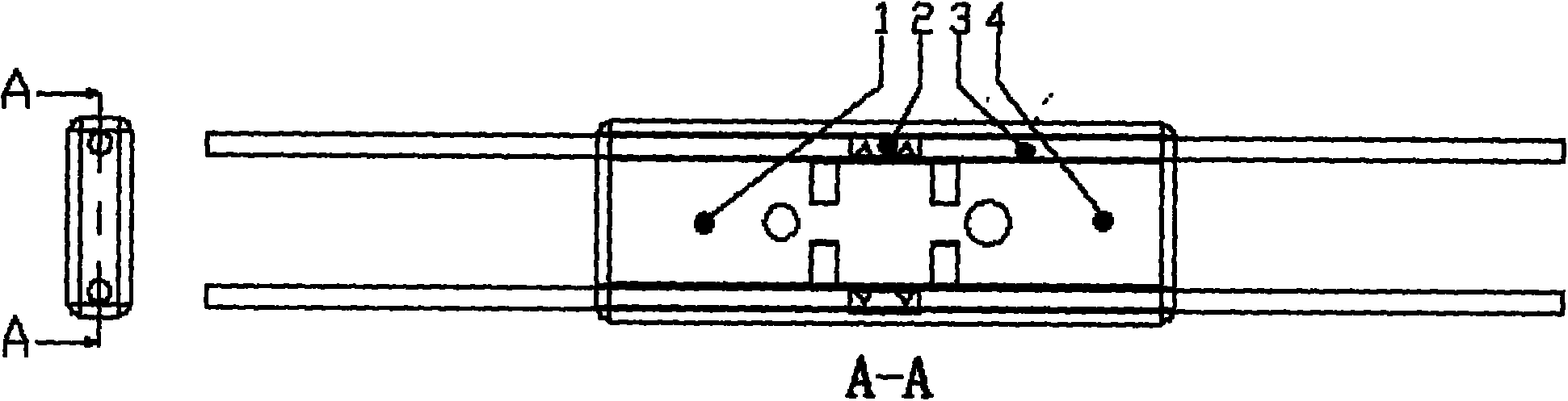

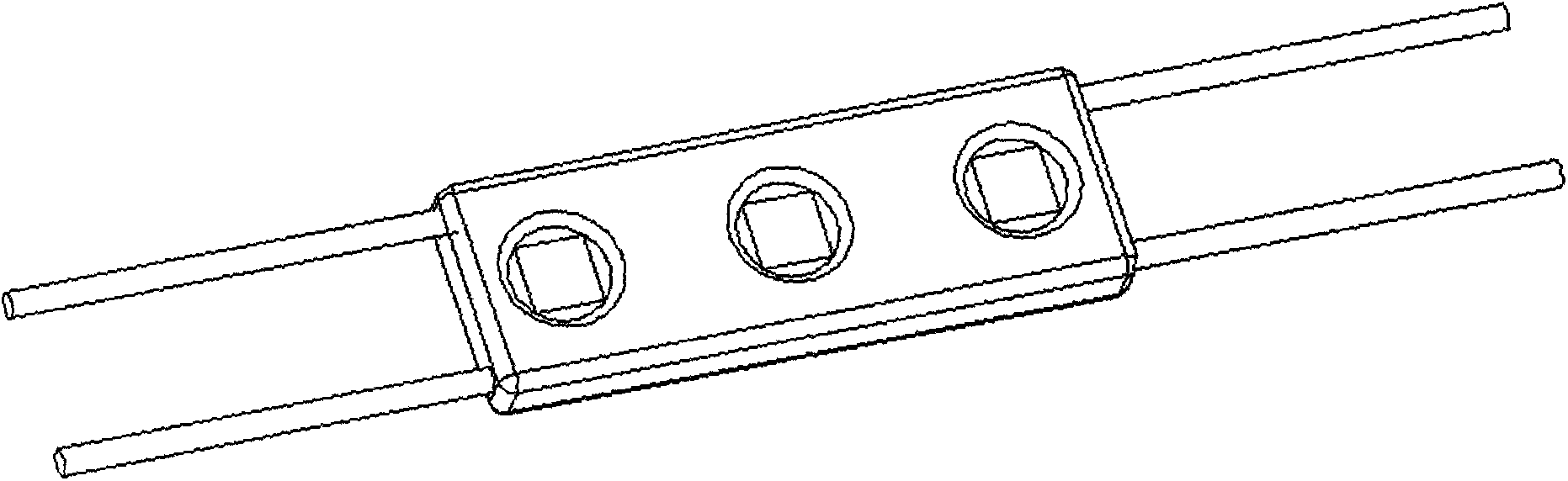

[0029] Such as figure 1 , figure 2 and image 3 As shown, the LED injection molding module described in this example includes a PCB board 1 provided with several LED lamp beads, a U-shaped line card 2, an electronic line 3, and an injection molded housing 4, wherein the electronic line 3 is realized through the U-shaped line card 2 Electrical conduction with the PCB board 1, the injection molded shell 4 tightly wraps the entire PCB board 1, U-shaped line card 2, and electronic wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com