Reference block group used for ultrasonic detection of austenitic stainless steel welding seams

A technology of austenitic stainless steel and comparative test block, which is applied in the direction of material analysis, measuring device and instrument using sonic/ultrasonic/infrasonic wave, can solve the problems of poor sensitivity of comparative test block and inconvenience to carry, avoid sidewall interference, Easy to carry and compact to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

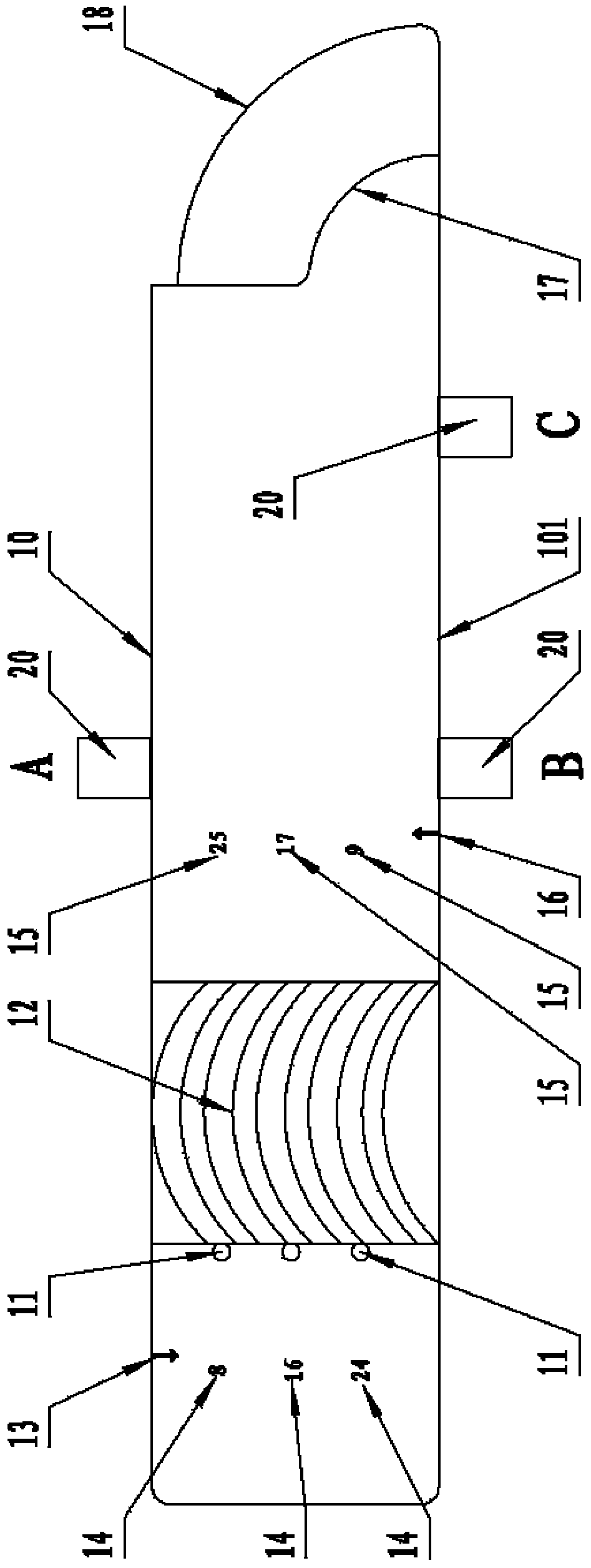

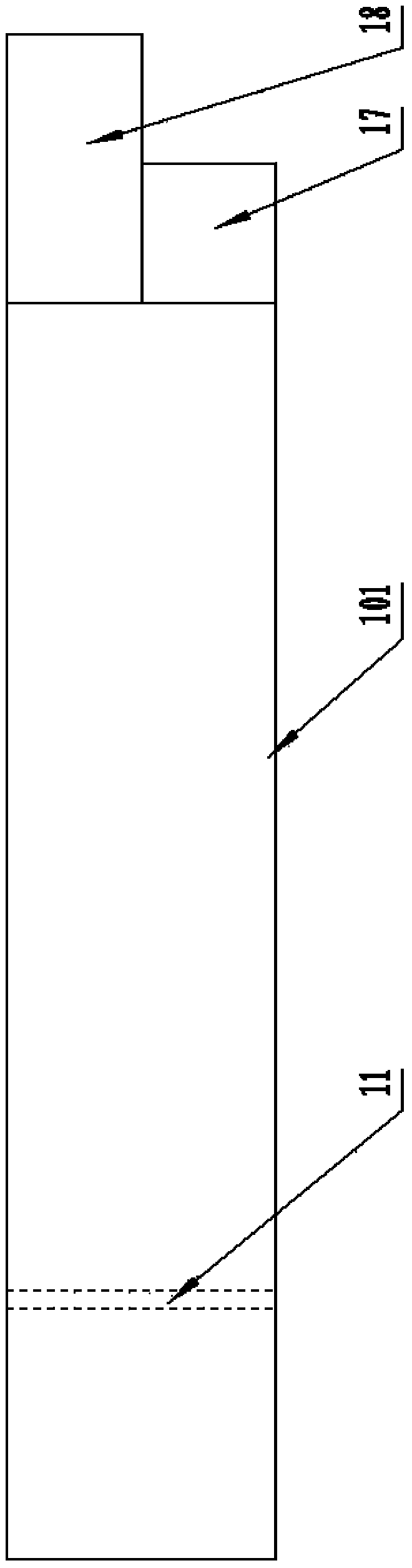

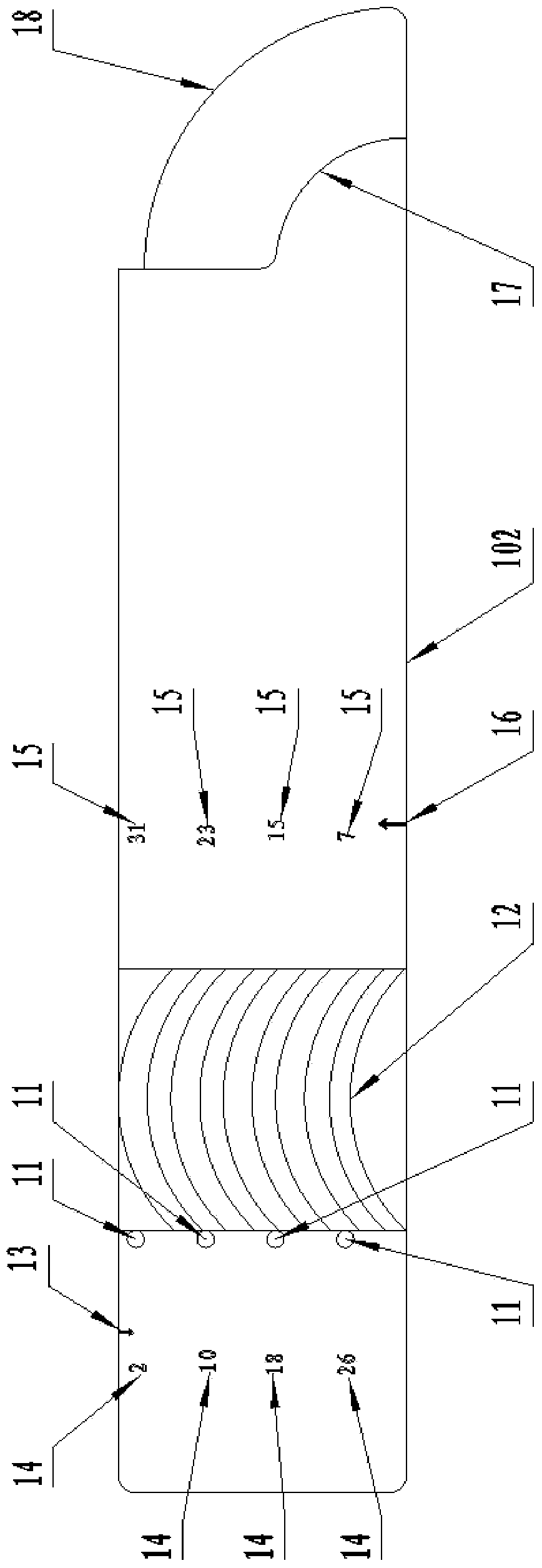

[0023] The comparative test block group for ultrasonic testing of austenitic stainless steel welds according to the present invention will be further described in detail below in conjunction with the accompanying drawings. A comparison test block group for ultrasonic testing of austenitic stainless steel welds, comprising a plurality of comparison test blocks 10, each side of the comparison test block 10 is provided with a weld 12, and each comparison test block 10 contains at least one Through hole 11, the center line of through hole 11 is parallel to the upper surface of the comparison test block 10 where the through hole 11 is located, and the distance from the center line of all through holes 11 to the upper surface of the comparison test block 10 where the through hole 11 is located is first class difference series, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 shown.

[0024] Each comparison test block 10 adopts a steel plate with the same or simil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com