A temperature control switch detection automation equipment and detection method thereof

A technology of automation equipment and temperature-controlled switches, applied in the direction of program control, computer control, general control system, etc., can solve the problems that the detection data cannot be output uniformly, the output of temperature-controlled switches is huge, and the detection methods are backward, etc., to improve work efficiency, Improve work safety and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

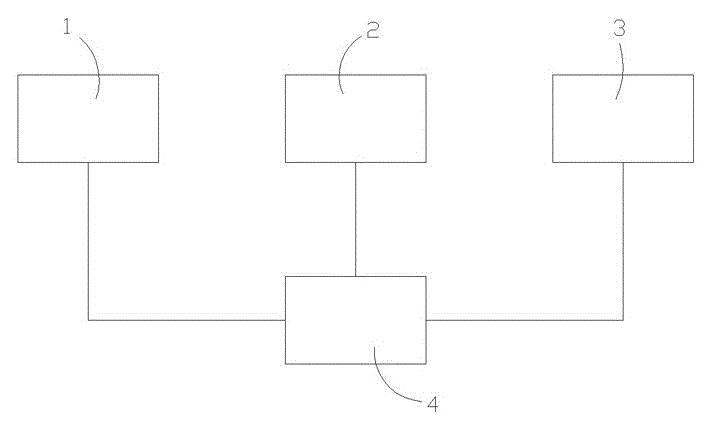

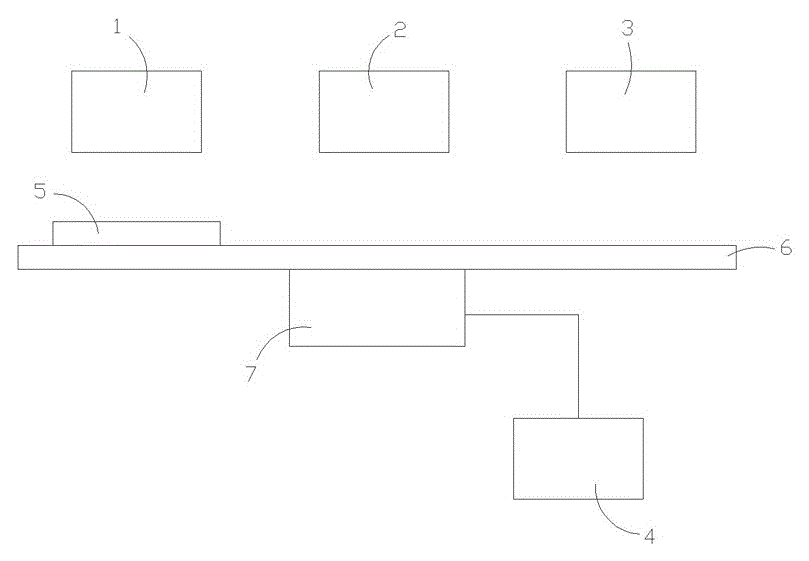

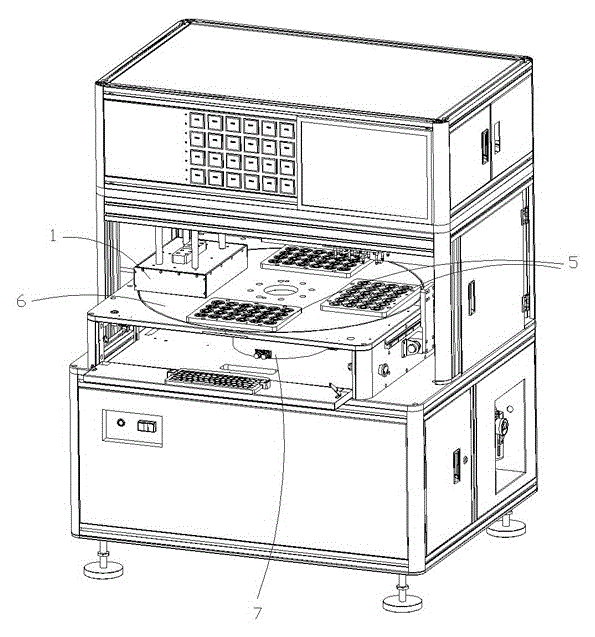

[0034] Such as Figures 1 to 7 As shown, a temperature-controlled switch detection automation equipment includes a heating detection unit 1 , a cooling detection unit 2 and a retrieving and sorting unit 3 .

[0035] The control unit 4 is respectively connected with the heating detection unit 1 , the cooling detection unit 2 and the retrieving and sorting unit 3 .

[0036] The working states of the heating detection unit 1 , the cooling detection unit 2 and the retrieving and sorting unit 3 are respectively controlled by the control unit 4 .

[0037] Firstly, the control unit 4 controls the heating detection unit 1 to enter the detection state, and the control unit 4 collects the heating detection results of the heating detection unit 1 .

[0038] Then, the control unit 4 controls the cooling detection unit 2 to enter the detection state, and the control unit 4 collects the cooling detection results of the cooling detection unit 2 .

[0039] Afterwards, after the heating dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com