Method for estimating development height of overlying strata water flowing fractured zone of solid filling and coal mining

A water-conducting fracture zone and solid filling technology, which is applied in seismology and other fields for logging records, and achieves the effects of low cost, simple and easy prediction method, and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

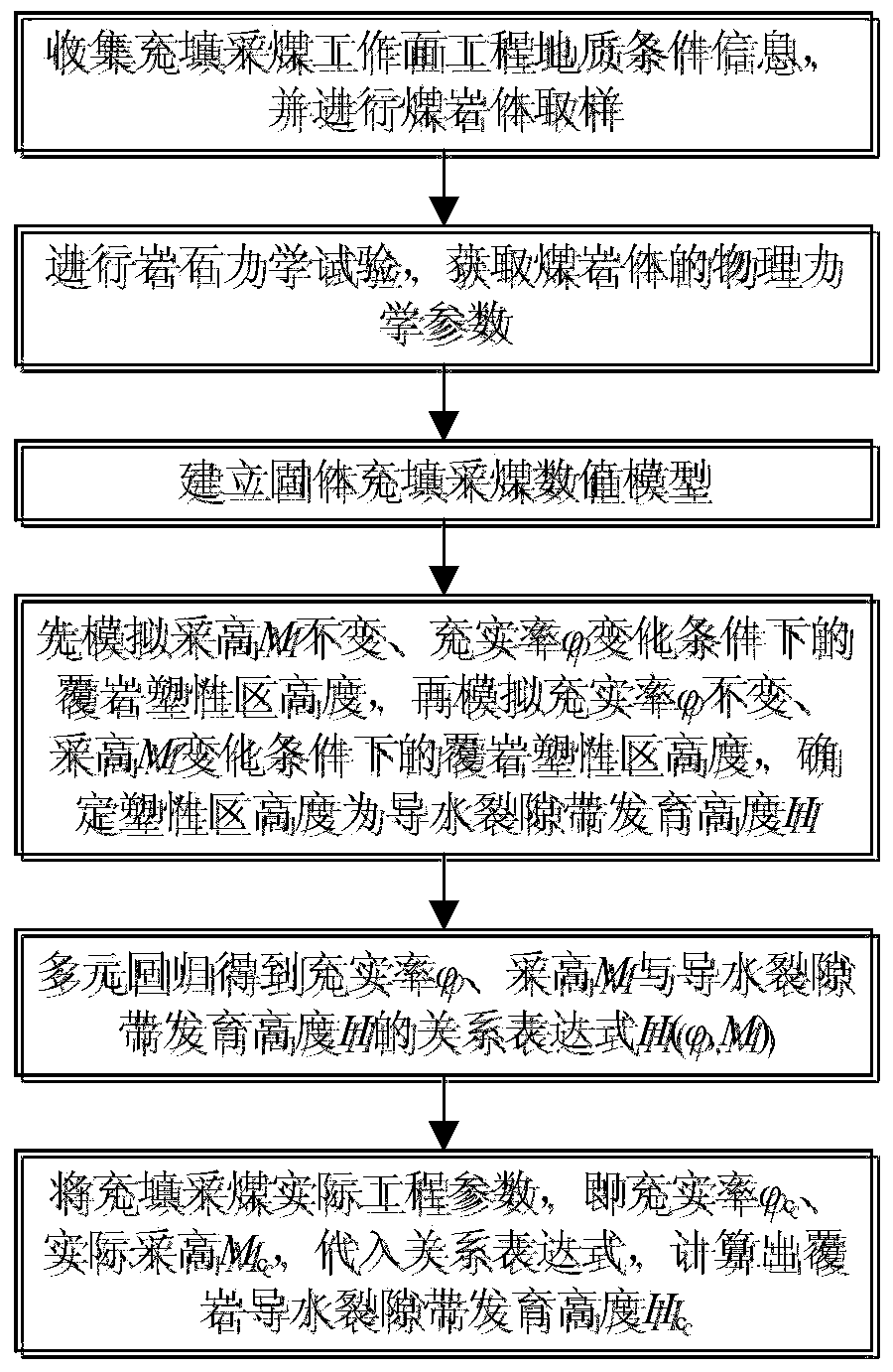

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, taking a certain coal mine as an example, the specific implementation steps are as follows:

[0028] (1) Conduct on-site investigations on the first mining face of solid filling coal mining in the coal mine, collect information on the engineering geological conditions of the working face, and take samples of coal and rock masses;

[0029] (2) The coal rock mass obtained by sampling was made into a standard sample, and the physical and mechanical parameters of the coal rock mass were obtained through rock mechanics tests, as shown in Table 1;

[0030] Table 1

[0031]

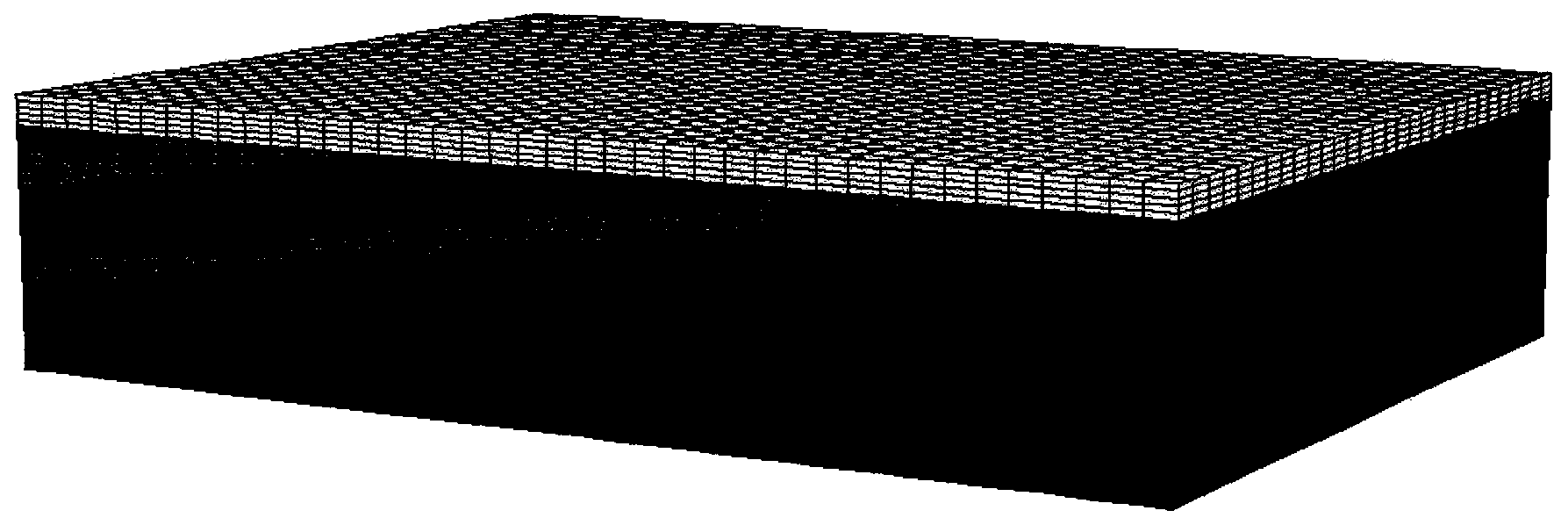

[0032] (3) According to the engineering geological conditions of the filling coal mining face and the physical and mechanical parameters of the coal and rock mass, the FLAC 3D The numerical simulation software establishes the numerical calculation model of solid filling coal mining, such as figure 2 shown;

[0033] The length × width × height of the model is 300m × 200m × 88m; the hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com