A dynamic prediction method for surface subsidence in solid filling mining

A technology of solid filling and surface subsidence, which is applied in the direction of filling, calculation, and ground mining, can solve problems such as building damage, large error in prediction results, and large differences in rock movement mechanisms, so as to achieve wide practicability and reduce mining costs. The effect of low dynamic damage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

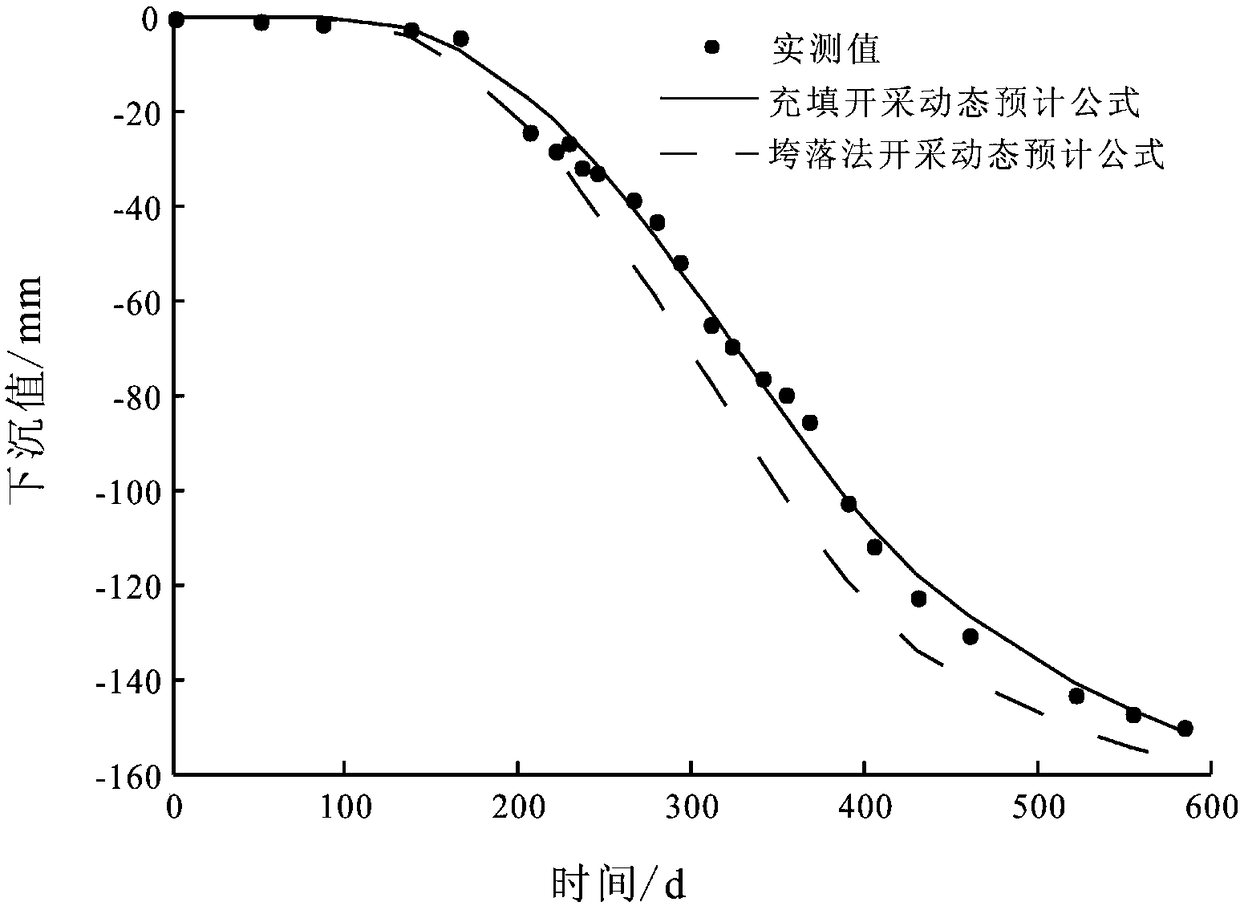

[0026] Take a solid filling face in a certain mine as an example:

[0027] 1) Determine the estimated parameters according to the geological conditions of the mining area

[0028] The average mining thickness of the coal seam is m=2.7m, and the average mining depth is H 0 = 440m, strike length L = 315m, and the estimated inclination length of the working face is l = 115m. Mining began in October 2012 and ended in December 2013. The average mining speed is about v = 0.8m / d, and the final filling rate η is 70%;

[0029] According to the average mining thickness m of the coal seam and the final filling rate η, calculate the equivalent mining thickness m e =m(1-η)=810mm;

[0030] The influence coefficient of rock movement time is c 1 =0.0059, the time influence coefficient c of the filling body 2 Take 0.02, sinking coefficient q=0.52, main influence tangent tanβ=2.2;

[0031] According to the main influence tangent and average mining depth, the main influence radius r=H can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com