Hard film, and polarized plate and image display device including same

A hard coating, hard coating technology, applied in optics, coatings, optical components, etc., can solve the problems of hard coating cracking, showing peeling, etc., to prevent interface reflection, prevent interference fringes, improve The effect of lightfast adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

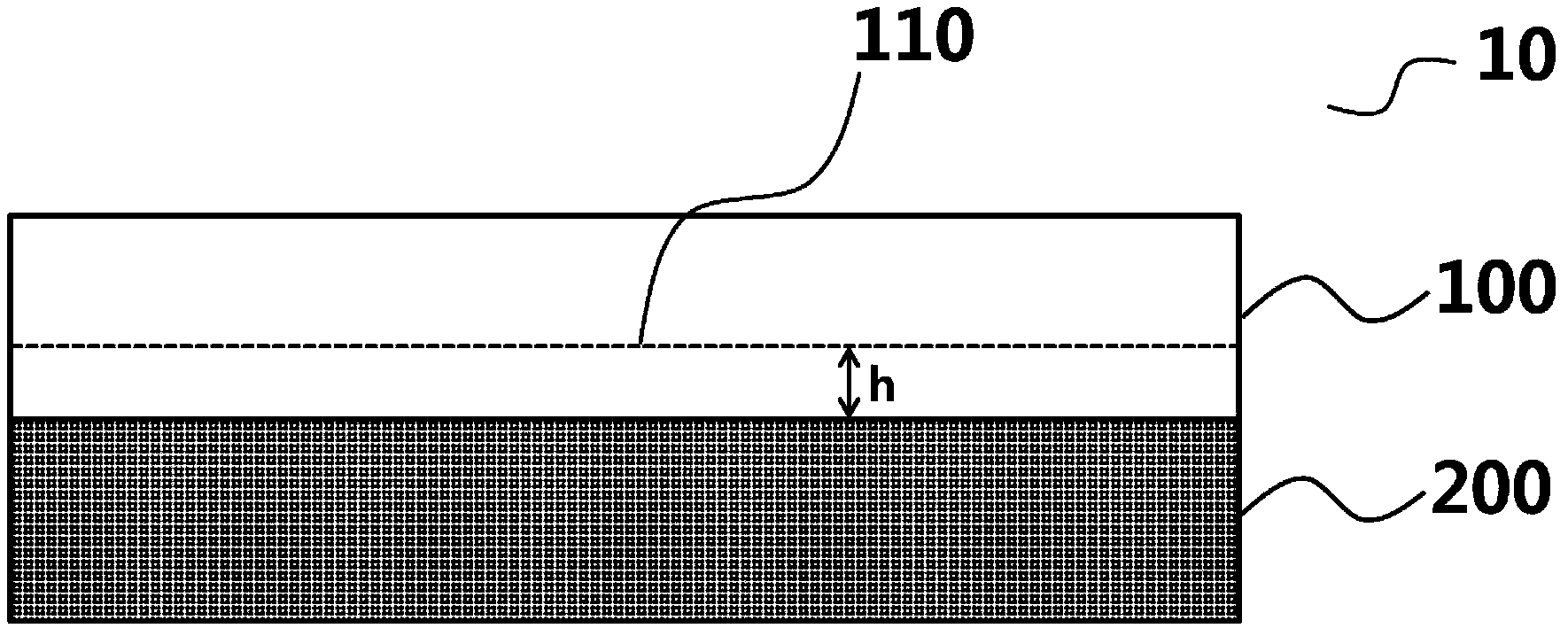

Image

Examples

Embodiment 1-6 and comparative example 1-4

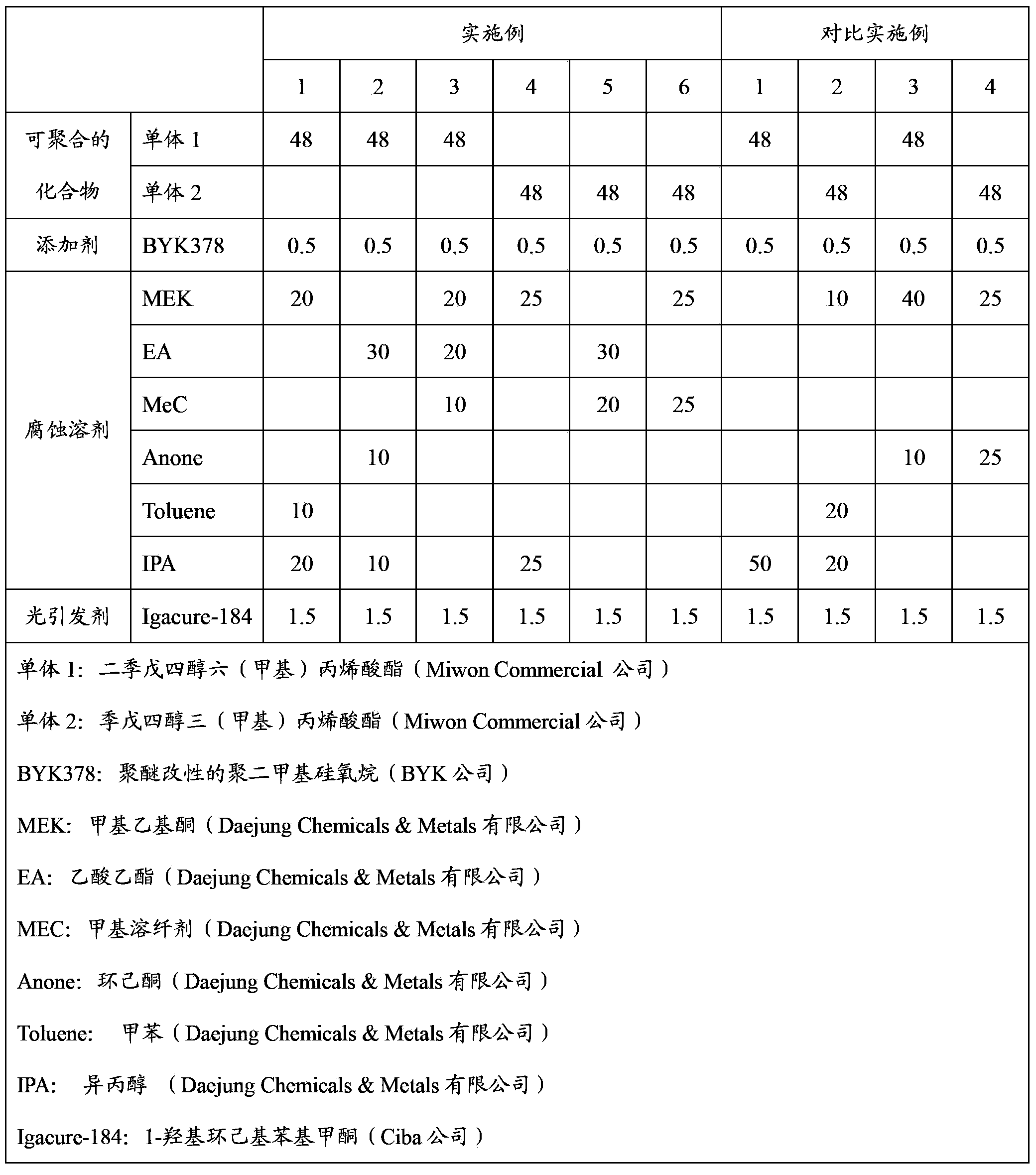

[0060] A composition for forming a hard coat layer was prepared using the components given in Table 1 below.

[0061] Table 1

[0062]

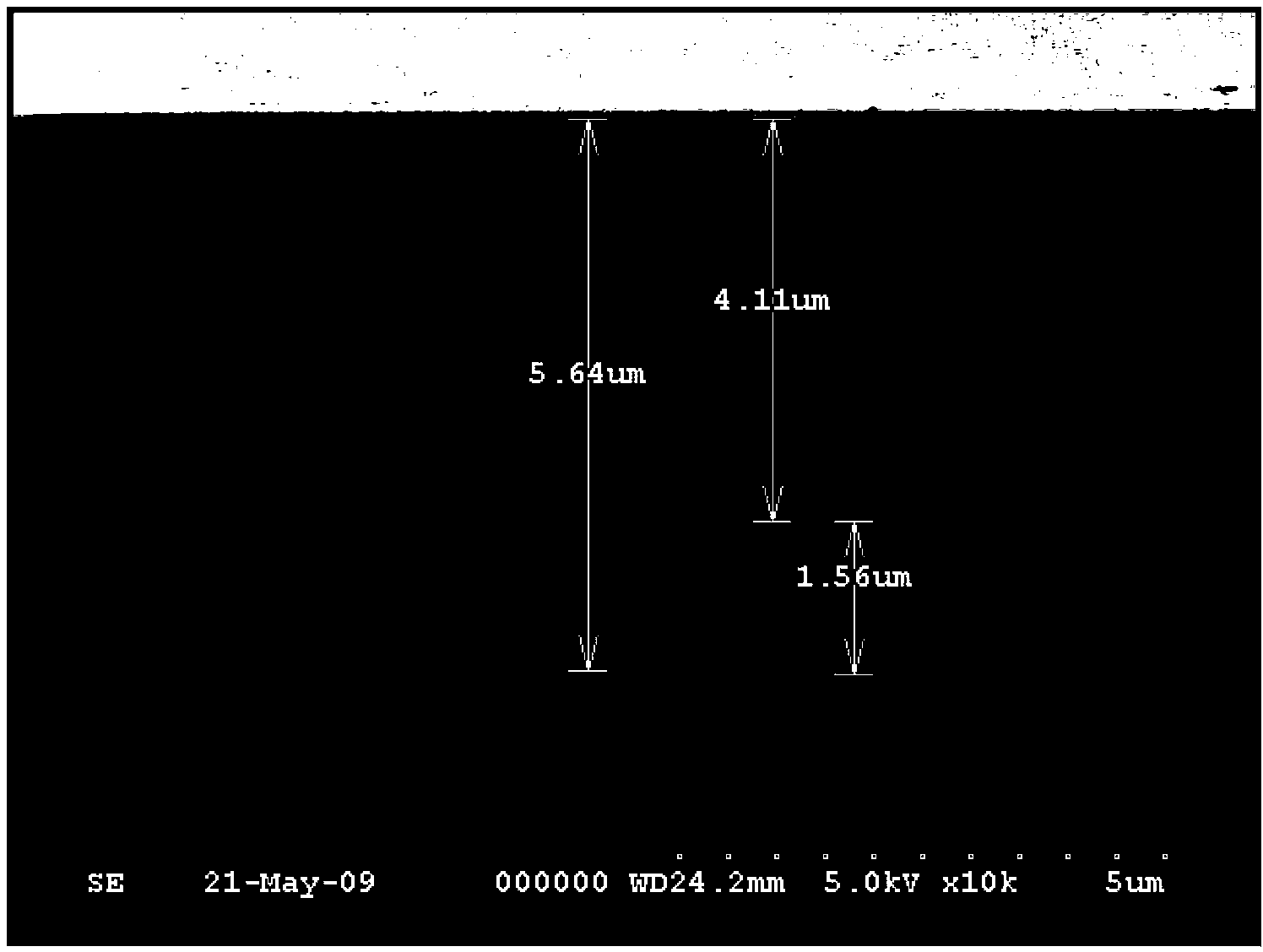

[0063] After stirring the various hard coating compositions prepared in the above Examples and Comparative Examples for 1 hour, the compositions were applied on a transparent base film (80 μm, TAC) up to 7 μm using a Mayor bar (a gravure coater) thickness, then, dried at 70°C for 2 minutes, followed by passing at 520mJ / cm 2 Cured under ultraviolet light to prepare a hard coating with a hard coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com