Structure of compensation filter device in multi-sequence laser shadow photography

A technology for compensating filter devices and laser shadows. It is applied to filters, cameras, installations, etc. for photographic purposes. Satisfy the effect of normal sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

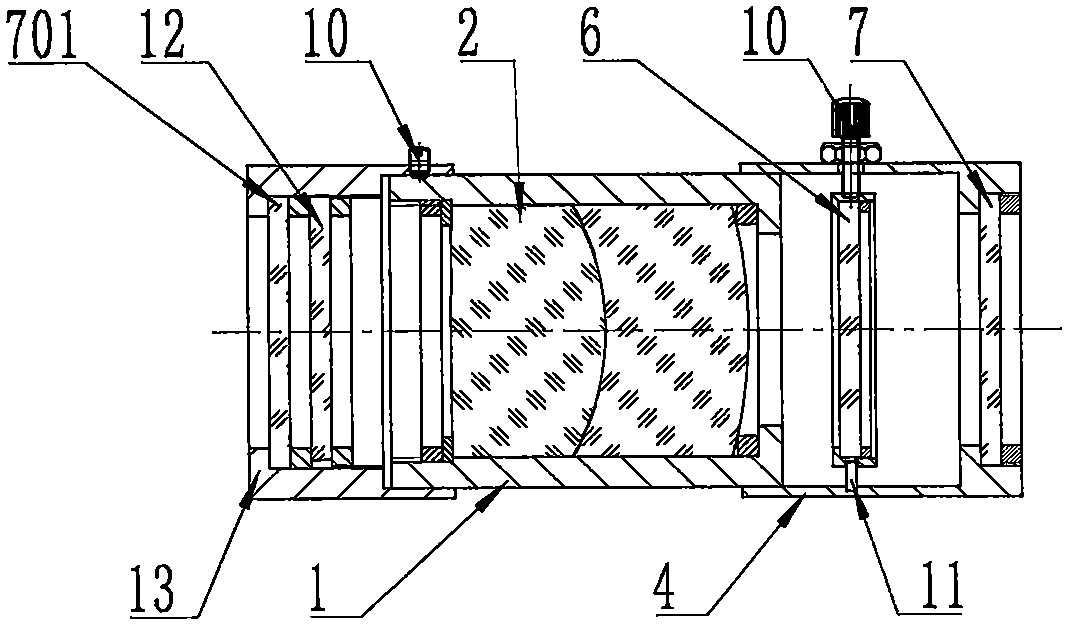

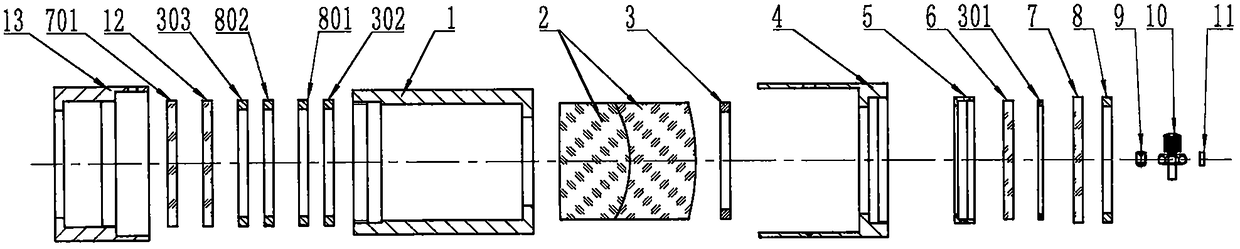

[0020] A compensation filter device structure in multi-sequence laser shadow photography, such as figure 1 and figure 2 As shown, it includes a main body sleeve 1, an imaging objective lens 2, a first gasket 3, a filter adjusting cylinder 4, a filter fixing cylinder 5, a filter 6, a second gasket 301, a first protective window glass 7, a second A pressure ring 8, a limit nail 9, a locking screw 10, a limit rod 11, a third washer 302, a second pressure ring 801, a third pressure ring 802, a fourth washer 303, a density gradient filter 12, the first Two protective window glass 701 and density gradient filter adjustment cylinder 13;

[0021] The front and rear ends of the main body sleeve 1 are respectively placed with the first protective window glass 7 and the second protective window glass 701, and the second protective window glass 701 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com