Manufacturing process of radial superconducting shimming coils

A shim coil and manufacturing process technology, applied in superconducting magnets/coils, coil manufacturing, magnetic objects, etc., can solve the problems of difficult mass production, poor manufacturing accuracy, and cumbersome operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

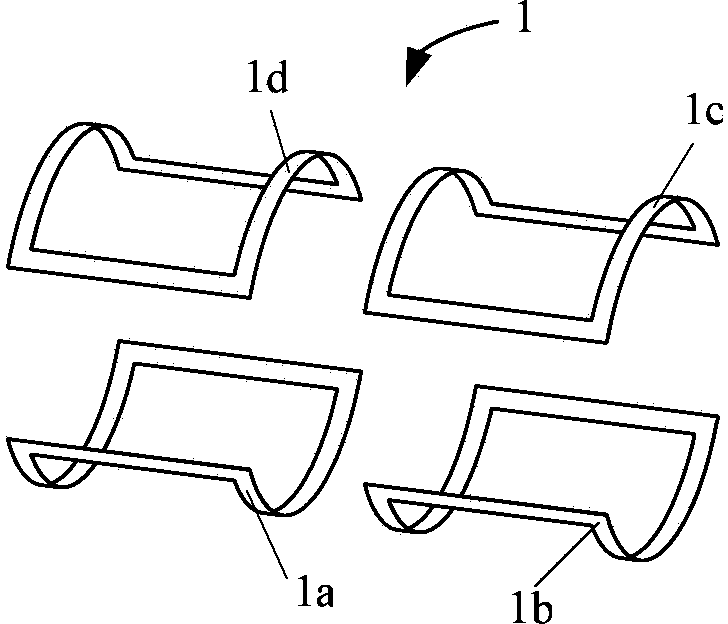

[0020] This embodiment is directed to the manufacturing method of the first radial superconducting shim coil composed of four saddle coils.

[0021] The steps of making the first radial superconducting shim coil in the present invention are as follows:

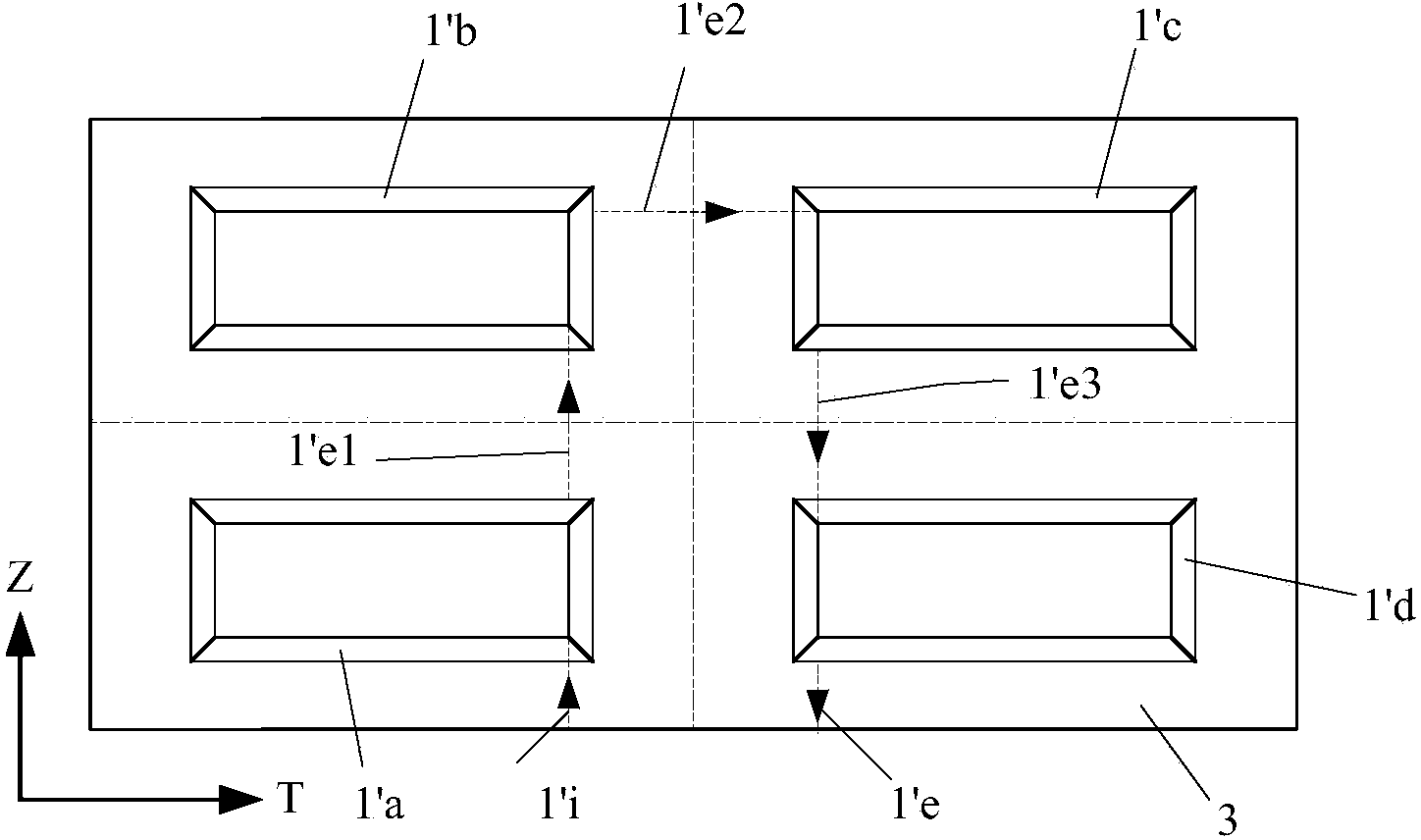

[0022] 1. will figure 1 The radial superconducting shim coil 1 shown in the three-dimensional space is expanded into a rectangular plane, and a rectangular ring of four saddle coils in the plane is drawn, and the radial superconducting shim coil of actual size is printed on the film substrate 3 The planar coil profile, such as image 3 As shown, the rectangular rings 1'a, 1'b, 1'c and 1'd including four saddle coils, and the incoming wire path 1'i, the outgoing wire path 1'e and the wire routing path 1'e1~1 'e3, the material of the film base is a transparent polyester film; the film base 3 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com