Production line for sawing, sorting, and recycling waste storage batteries

A waste battery and production line technology, which is applied in the recycling production line, sorting, and sawing of waste batteries, can solve the problems of air and water pollution, ecological environment damage, and insufficient automation, so as to achieve reuse, avoid contact, and avoid pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and working principles, but it is not intended to limit the protection scope of the present invention.

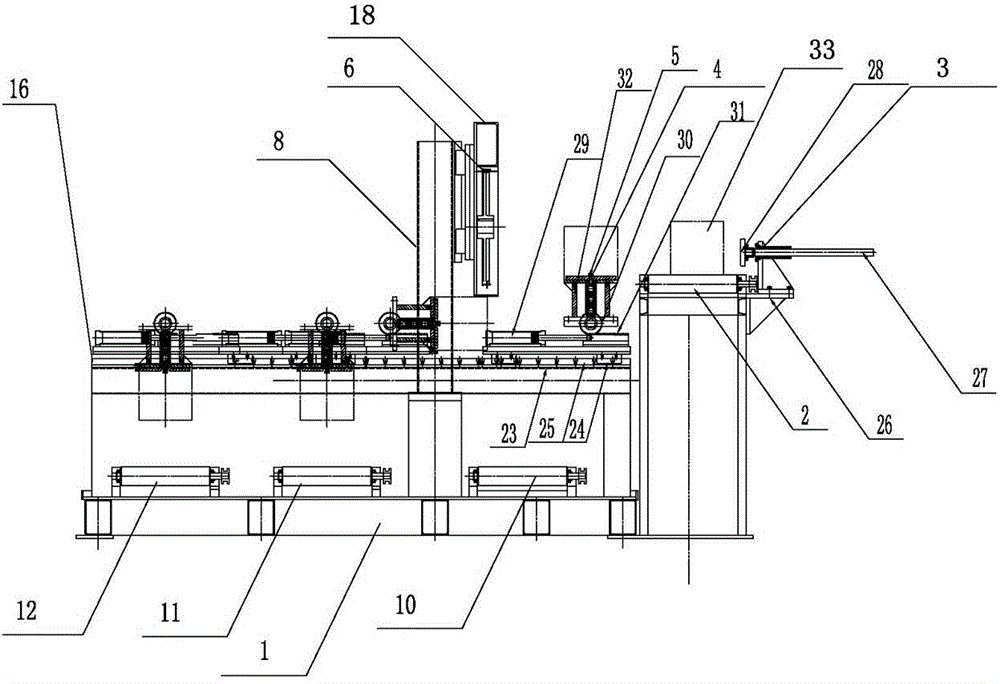

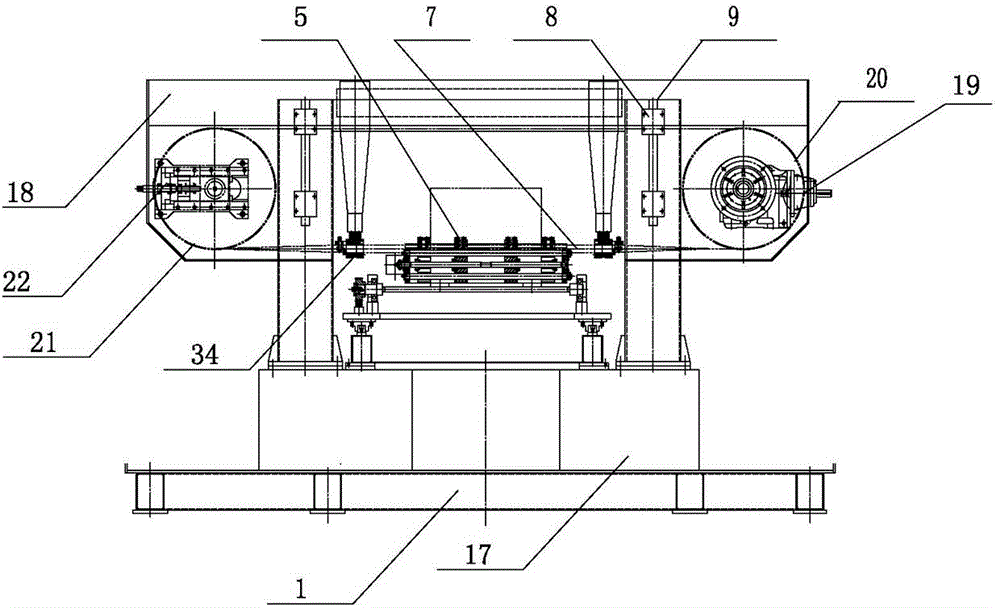

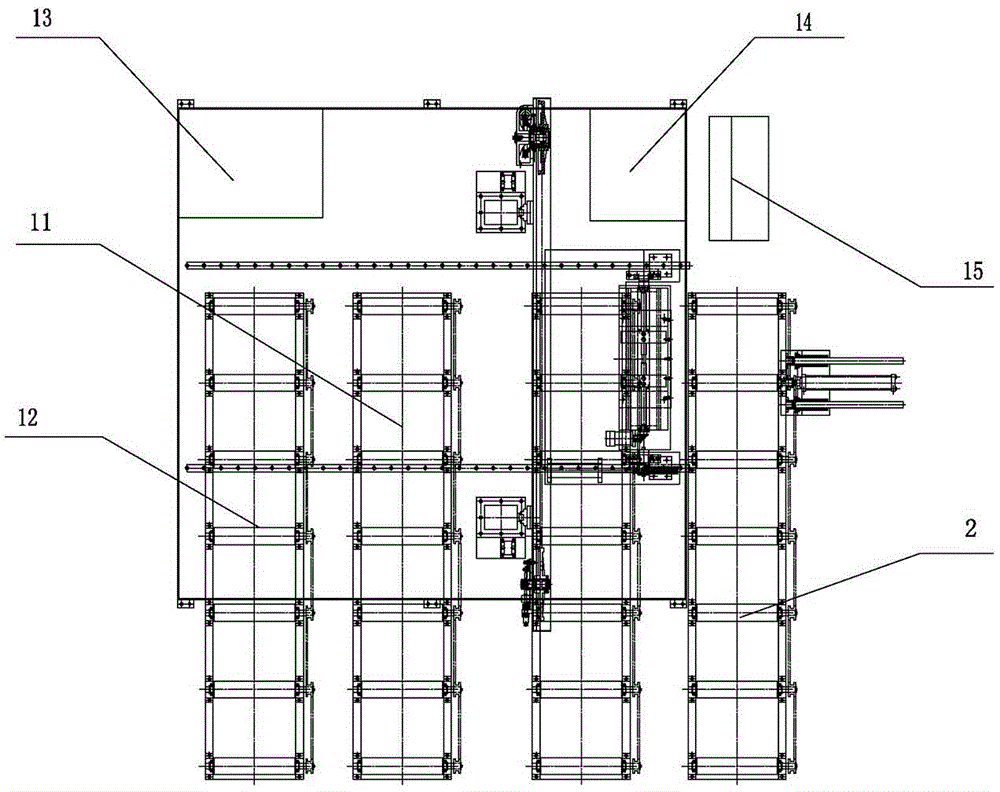

[0020] Such as Figure 1-3 As shown, a waste battery sawing, sorting, and recycling production line includes a base 1, a battery input roller table 2, a sawing device 6 arranged on the base 1, a hydraulic system 14, and an electrical system 15. There are sawing conveying track 16, battery cover collecting roller table 10, plate collecting roller table 11 and battery box collecting roller table 12, the height of battery cover collecting roller table 10, plate collecting roller table 11 and battery box collecting roller table 12 Lower than the height of the sawing conveying track 16, the sawing conveying track 16 is provided with a servo overturning trolley 4, the height of the servo overturning trolley 4 matches the height of the sawing device 6, and the batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com