Method for sterilizing laundry, and washing-drying unit

A drying unit, clothing technology, applied in washing devices, household dryers, control devices of washing machines, etc., can solve problems such as failure to achieve success and cannot be realized in practice, and achieve the effect of small damage and shrinkage prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

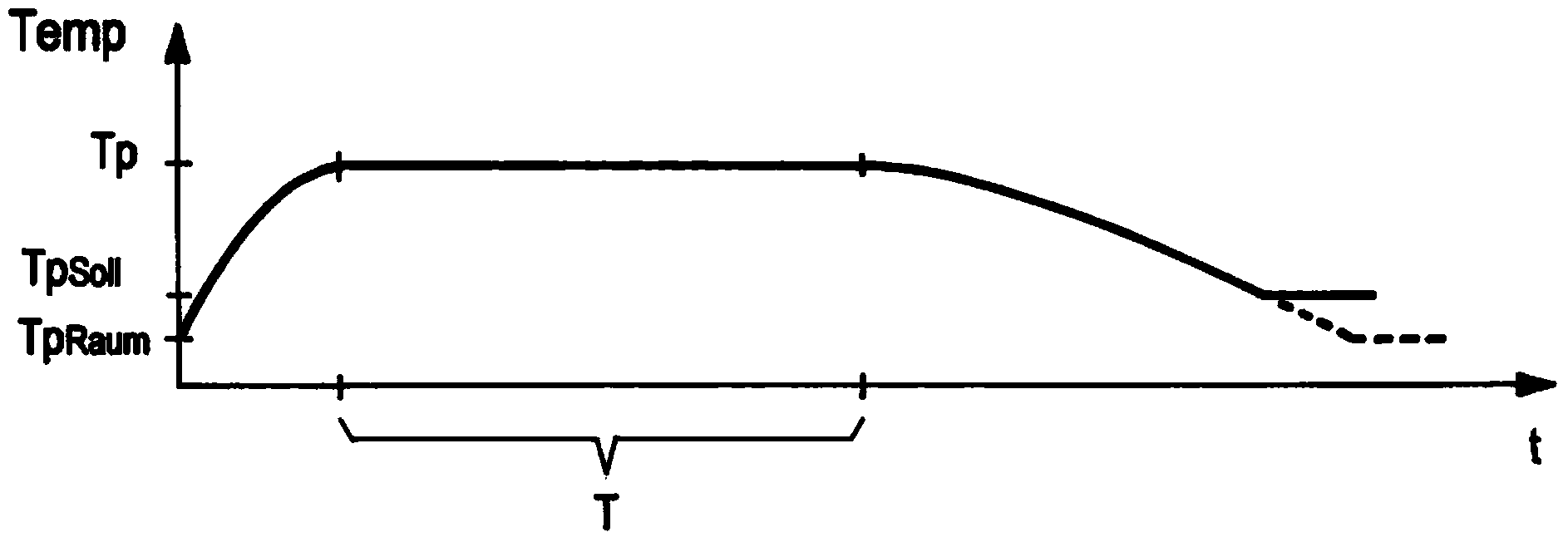

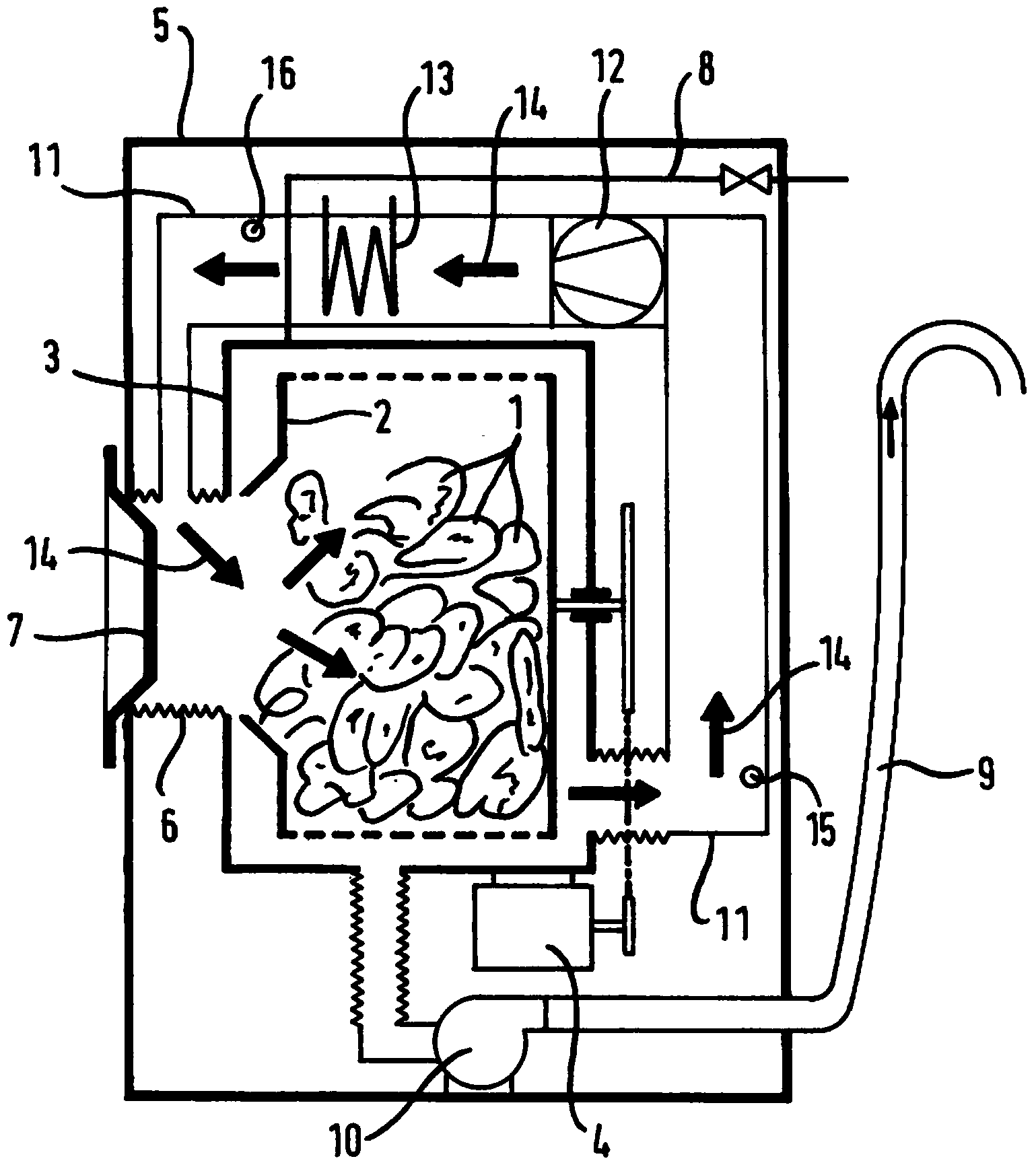

[0029] In this method, the laundry to be washed, ie the laundry items to be washed, is heated by means of a flow of process air while still in a dry state, ie before the actual washing process starts. The heating is carried out to a defined temperature Tp, which is specified in a fixed manner or can be preselected by the device performing the heating. Here, said defined temperature Tp is advantageously pre-selected to fall within the range of 60°C-120°C, especially 70°C-90°C inclusive. Once a defined temperature Tp is reached, the laundry is exposed to this temperature for a predetermined time period T, wherein the specified time period T is in the range of five to twenty-five minutes, especially in the range of ten to twenty minutes (including endpoints). Said time period T is specified in a fixed manner or is preselected by the means for heating. The heating in the stream of hot air performs the desired disinfection, in particular almost completely kills the microorganisms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com