Orientation atomizing device for cotton operation

A technology for working and cotton, applied in the field of mist mist in cotton fields, can solve the problems of heavy labor, pesticide loss, pesticide poisoning, etc., to protect the ecological environment, reduce the loss of liquid medicine, and improve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

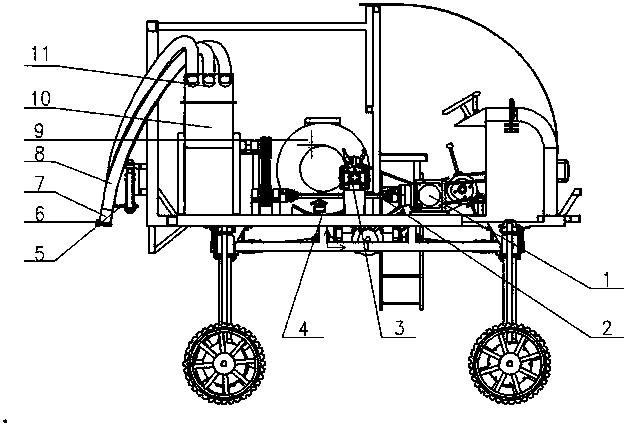

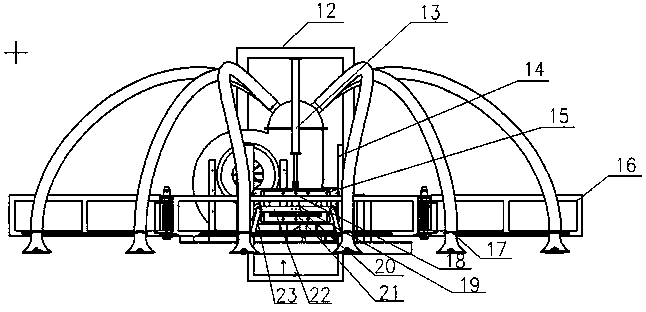

[0023] Implementation case: the present invention uses the cotton field self-propelled high-gap universal frame to combine the power system, transmission system, high-pressure spray system, multi-channel air delivery system, directional mist device, etc. through rational arrangement and layout; the actual When working in the field, this directional misting device for cotton operations will make corresponding adjustments according to the on-site growth conditions of local cotton. When the growing height of cotton becomes larger, the hydraulic cylinder (13) on the rectangular fixed frame (12) will be lifted accordingly according to the degree of change in the growing height of cotton, so as to always maintain the energy of the airflow blown from the duckbill air outlet (7). Make the fog droplets blow to the target under stress, and at the same time, the airflow can turn the branches and leaves, so that the back, surface and top and bottom of the leaves of the crops can be evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com