Solid-liquid filtering device

A technology of solid-liquid filtration and frame body, applied in the direction of fixed filter element filter, filtration separation, gravity filter, etc., can solve the problems of low operation efficiency and high labor intensity, improve operation efficiency, reduce labor intensity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

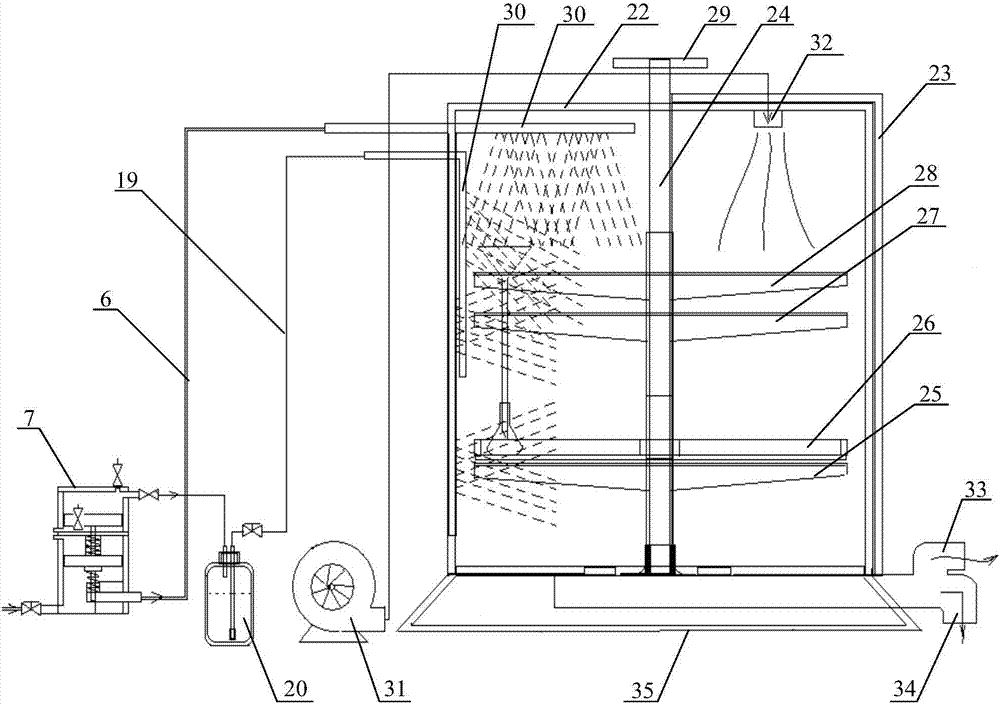

[0032] like figure 1 , 2 As shown, the solid-liquid filtering device of the present invention includes a frame body 22. The frame body 22 in this embodiment is cylindrical as a whole, and the frame body 22 can also be in other shapes. The frame body 22 has a cavity inside, and the cavity in this embodiment is also cylindrical as a whole. A base 35 is also provided at the bottom of the frame body 22 , and an opening is provided on the side wall of the frame body 22 . The opening of the frame body 22 is provided with a door body 23 that closes the opening. The door body 23 can be connected to the frame body 22 through hinges, or can be connected to the frame body 22 by means of a push-pull structure. The frame body 22 is independent of each other. When the door needs to be closed, the door body 23 is fastened to the opening of the frame body 22, and when the door needs to be opened, the door body 23 can be directly removed.

[0033] Inside the frame body 22 is a tray device fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com