Off-line cleaning device for a counter-current electrostatic desalination membrane block

A cleaning device and electrostatic desalination technology, applied in the direction of semi-permeable membrane separation, membrane technology, separation methods, etc., can solve the problems of membrane module waste, product water quality deterioration, lack of membrane module cleaning technology, etc., to achieve fast and convenient installation And disassembly, cleaning effect excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

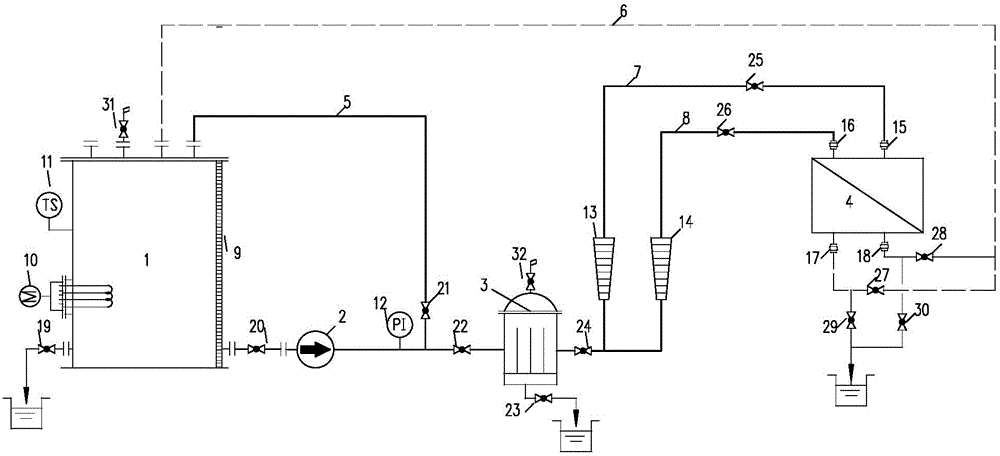

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] see figure 1 , the present invention comprises that the side wall is provided with a water outlet, and the top is provided with a solution tank 1 with a bypass inlet and a return inlet, and the water outlet of the solution tank 1 passes through the solution tank water outlet valve 20, the cleaning water pump 2, the filter inlet valve 22 and cleaning The filter 3 is connected, and the outlet of the cleaning water pump 2 is provided with a pressure gauge 12 for detecting the outlet pressure of the cleaning water pump 2; the bypass inlet on the top of the solution tank 1 is connected with a return bypass 5 with a bypass valve 21, and the return flow The bypass 5 is connected to the pipeline between the cleaning water pump 2 and the cleaning filter 3; the outlet main pipe of the cleaning filter 3 is provided with a filter outlet valve 24, and the main wate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap