Meat grinder with blending function

A meat grinder, functional technology, applied in the field of meat grinder, can solve the problems of poor agglomeration of meat stuffing, firewood loose meat texture, etc., and achieve the effect of good water holding capacity, strong agglomeration ability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

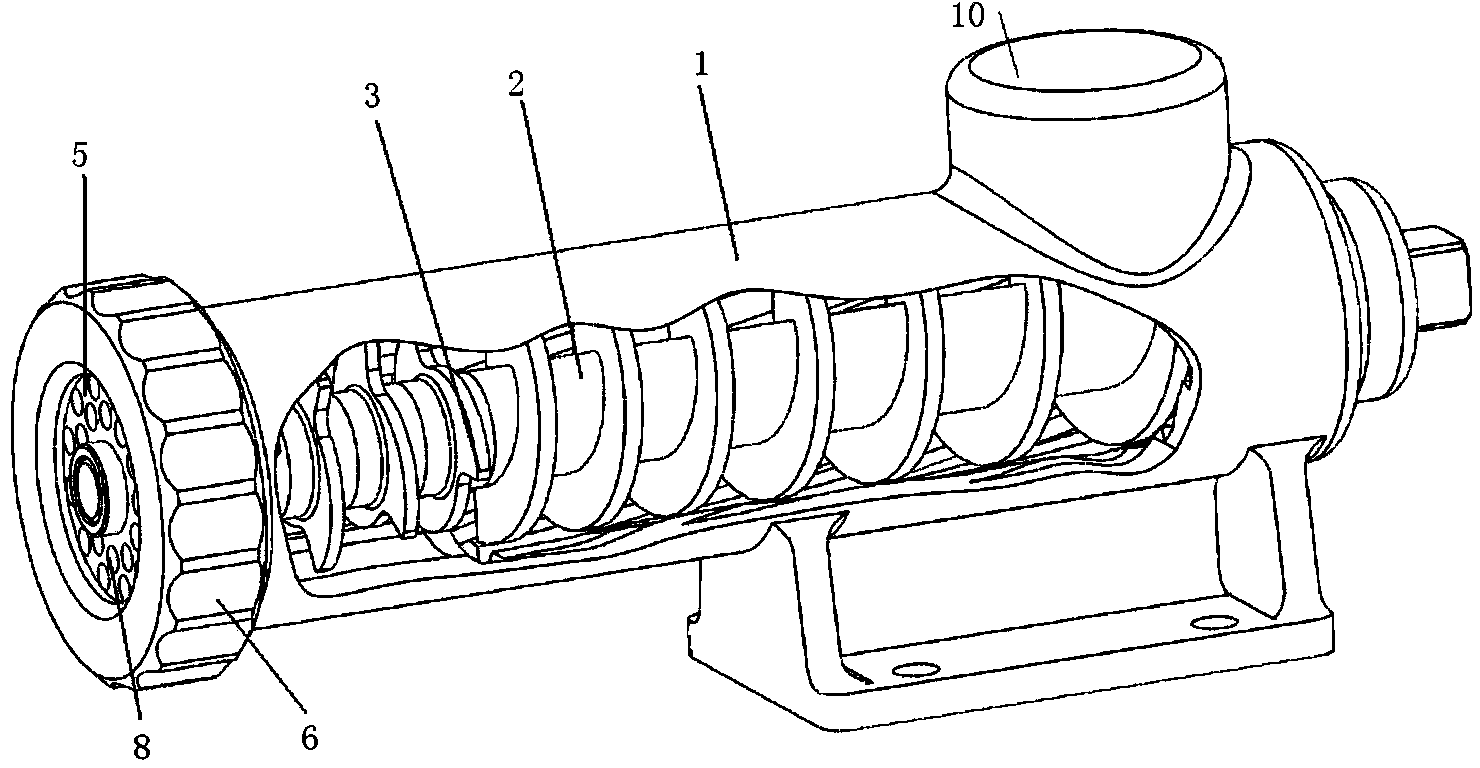

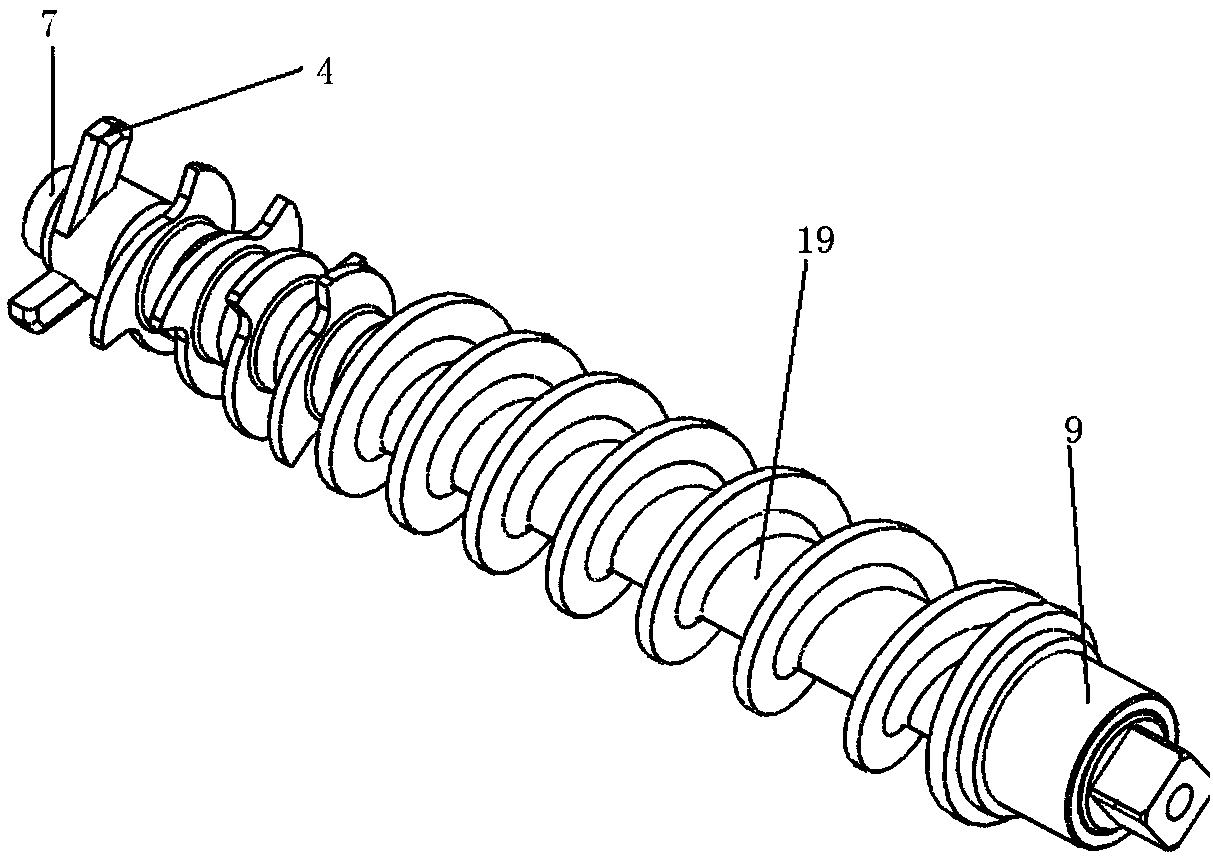

[0033] A meat grinder with crushing function is composed of barrel 1, screw rod 2, beating claw wheel 3, cutter 4, hole plate 5, gland 6, front positioning bushing 7, and rear positioning bushing 9.

[0034] The rear section of the barrel 1 is provided with a feed port 10, the front section of the barrel 1 is provided with a hole plate positioning groove 11, the rear section of the inner wall of the barrel 1 is provided with 8 spiral conveying rifling lines 12 circumferentially, and the front section of the barrel 1 is provided with 6 The raised axially extrudes the rifling 13.

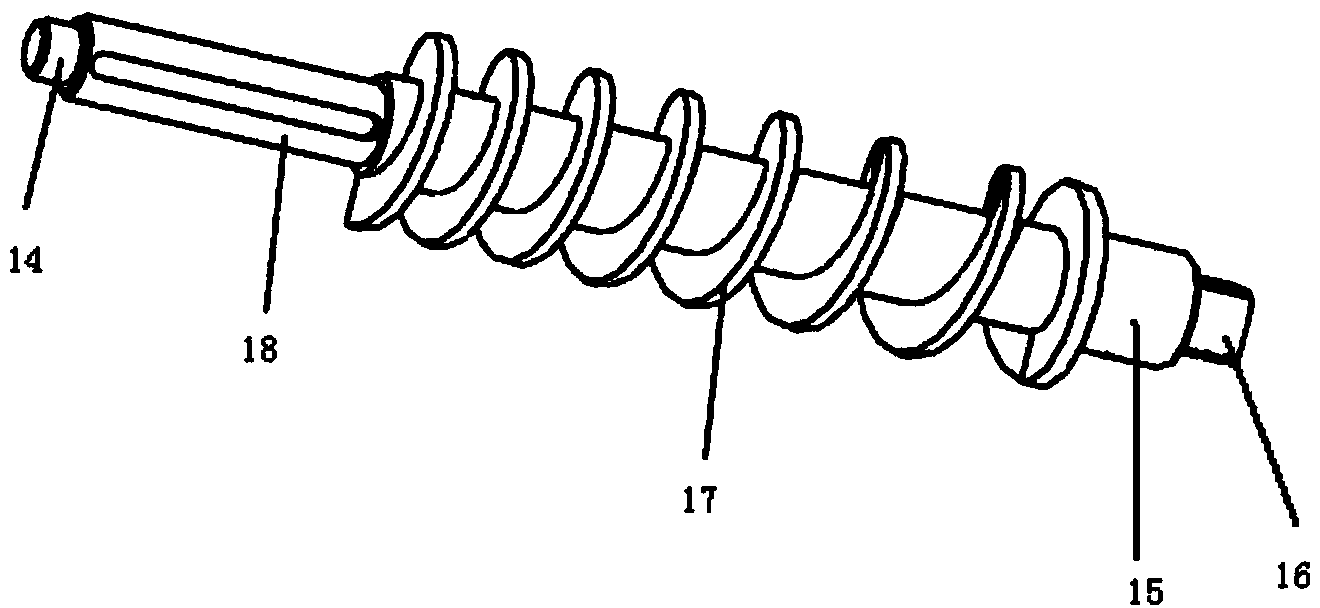

[0035] The front end of the screw rod 2 is provided with a front positioning journal 14, and the rear end is provided with a rear positioning journal 15 and a shaft head 16 for transmitting power. Fixed journal 18.

[0036] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com