In-situ reduction system for gas-phase pollutants at refuse landfill based on intercalation function layer

A landfill and functional layer technology, which is applied in the construction of intercalated functional layers in landfills, in-situ reduction of methane, malodorous gases, and in-situ reduction systems for gas phase pollutants in landfills, can solve the problem of Increase the cost of raw materials, the air is not easy to enter the interior of the garbage dump, etc., to achieve the effect of rich pore structure, long service life, and accelerated activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1. Construction of a new type of landfill intercalation functional layer in-situ deodorization system

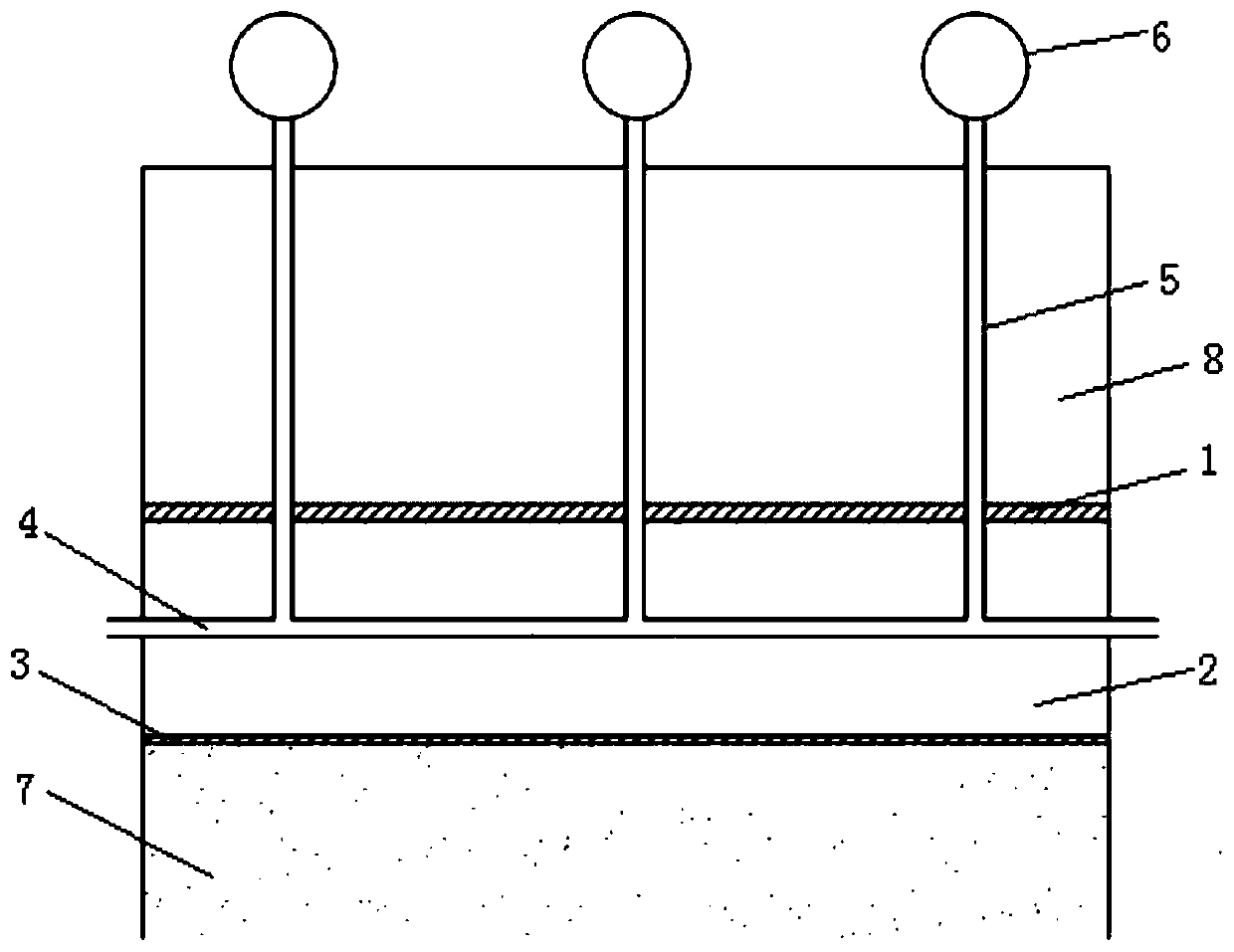

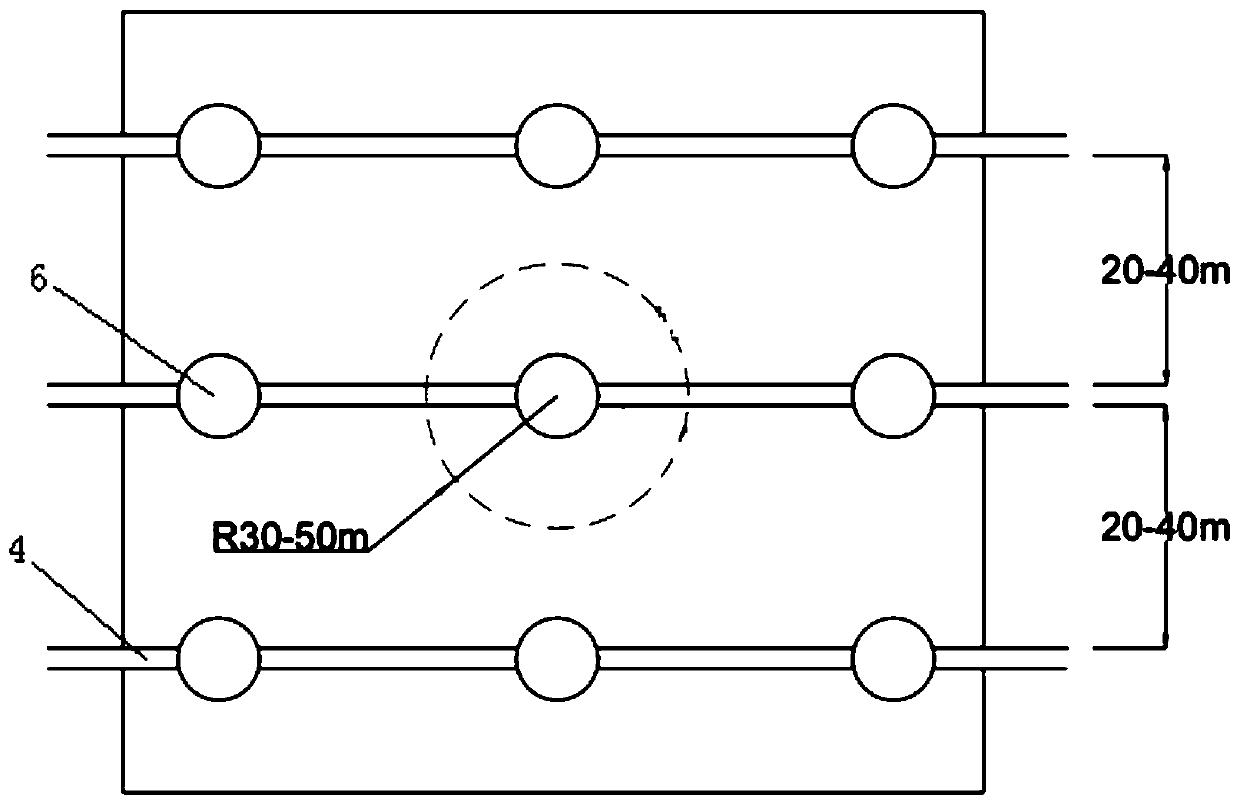

[0036] An in-situ reduction system for gaseous pollutants in landfills, such as figure 1 and figure 2 As shown, the intercalation type functional layer is included above the garbage dump body 7 of the landfill and below the closure covering system 8 . The intercalated functional layer includes a non-woven breathable film layer 3, a functional packing layer 2 and a HDPE film layer 1 arranged in sequence, and a non-powered automatic air exchange system is also arranged in the functional packing layer 2.

[0037] The preparation of the functional filler layer 2: First, take the garbage from the Laogang landfill for about 8-12 years, and after roughly sieving, the particle size is 6 -1×10 7 pieces / g of mineralized waste; the sludge charcoal is directly fired from the remaining sludge from the sewage plant at 500°C under anaerobic conditions; then the fired slud...

Embodiment 2

[0041] Example 2. Construction of a new type of landfill intercalation functional layer in-situ deodorization system

[0042] An in-situ reduction system for gaseous pollutants in a landfill site, comprising setting an intercalation-type functional layer above the garbage pile of the landfill site and below the closure covering system. The intercalated functional layer includes a non-woven breathable film layer, a functional packing layer and an HDPE film layer arranged in sequence, and a non-powered automatic air exchange system is also arranged in the functional packing layer.

[0043] The preparation of the functional packing layer: Firstly, the garbage from the Laogang landfill for about 8-12 years is taken, and after roughly screening, the particle size is 6 -1×10 7 pieces / g of mineralized waste; the sludge charcoal is directly fired from the remaining sludge from the sewage plant at 400°C under anaerobic conditions; then the fired sludge charcoal is buried in the mineral...

Embodiment 3

[0047] Example 3. Construction of a new landfill intercalation functional layer in-situ deodorization system

[0048] An in-situ reduction system for gaseous pollutants in a landfill site, comprising setting an intercalation-type functional layer above the garbage pile of the landfill site and below the closure covering system. The intercalated functional layer includes a non-woven breathable film layer, a functional packing layer and an HDPE film layer arranged in sequence, and a non-powered automatic air exchange system is also arranged in the functional packing layer.

[0049] The preparation of the functional packing layer: Firstly, the garbage from the Laogang landfill for about 8-12 years is taken, and after roughly screening, the particle size is 6 -1×10 7 pieces / g of mineralized waste; the sludge charcoal is directly fired from the remaining sludge from the sewage plant at 300°C under anaerobic conditions; then the fired sludge charcoal is buried in the mineralized was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com