Open separation system

A sorting system and sorting machine technology, applied in the field of sorting systems, can solve problems such as increasing operating costs, increasing models, and increasing investment, and achieves the effects of solving fan wear, blocking pipe problems, and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

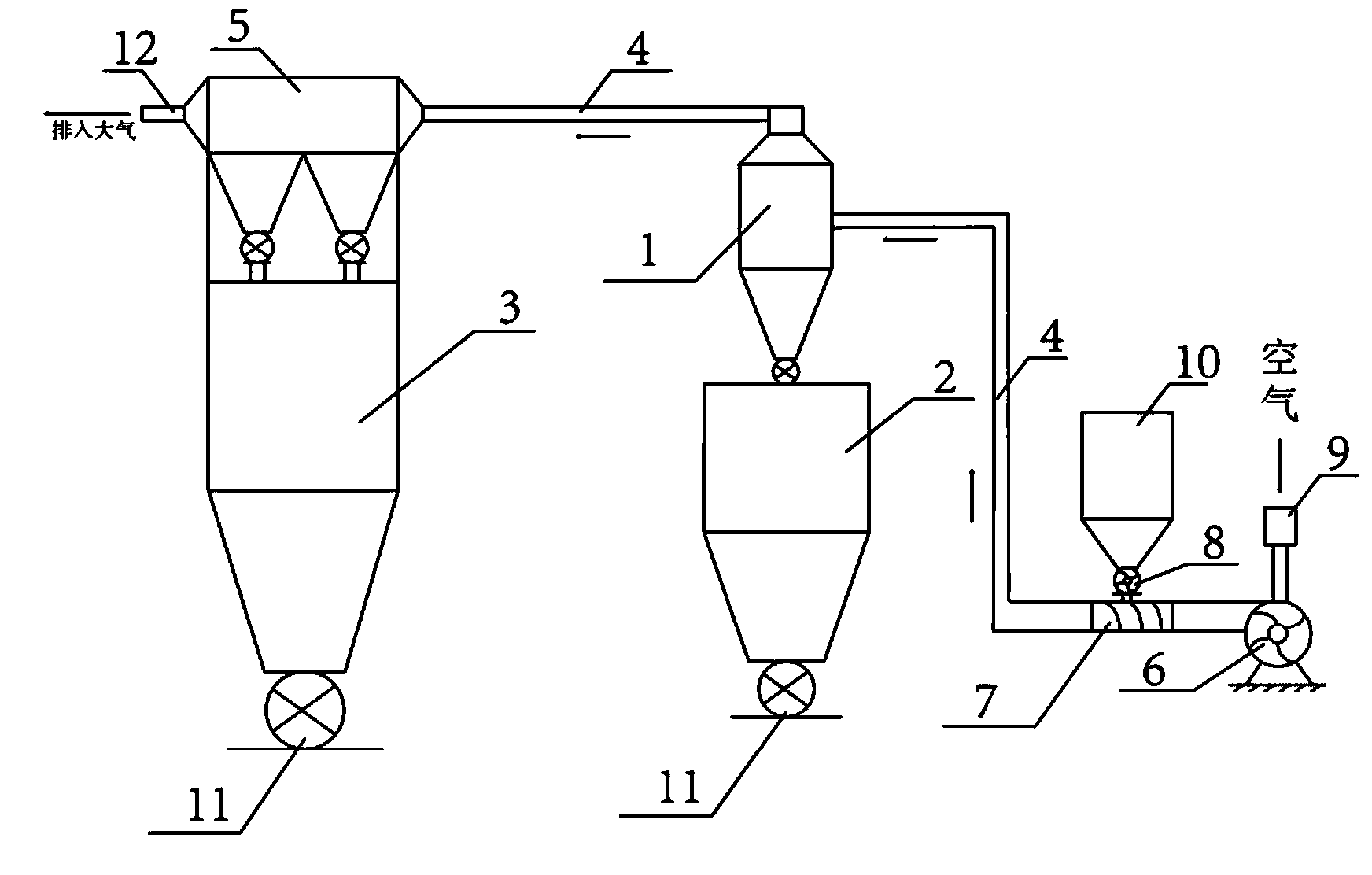

[0008] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

[0009] Referring to the accompanying drawings, the present invention includes a sorting machine, which is characterized in that: the lower end of the sorting machine 1 communicates with the coarse ash bin 2, and the upper end communicates with the bag dust collector 5 through the ash conveying pipe 4, and the bag dust collector The lower end communicates with the fine ash bin 3 , and the separator 1 communicates with the main fan 6 through the ash conveying pipe 4 and the ash gas mixer 7 , and the ash gas mixer communicates with the raw material bin 10 through the feeder 8 .

[0010] The fly ash enters the ash gas mixer 7 connected with the ash conveying pipe 4 through the raw material bin 10 and the feeder 8, and the main fan 6 also sends the inhaled air into the ash gas mixer 7 to stir and mix the fly ash. The dust-laden air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com