Cross wedge rolling precision forming method of axle shaft sleeve

A technology of precision forming and cross wedge rolling, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of axial movement, difficulty of economical rolling of half shaft casing in cross wedge rolling, end flattening, etc. , to achieve the effect of small machining allowance, meeting performance requirements and small wall thickness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

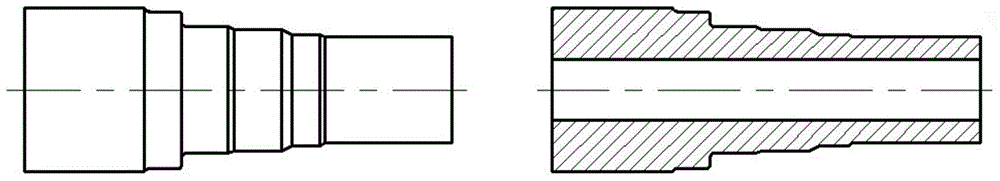

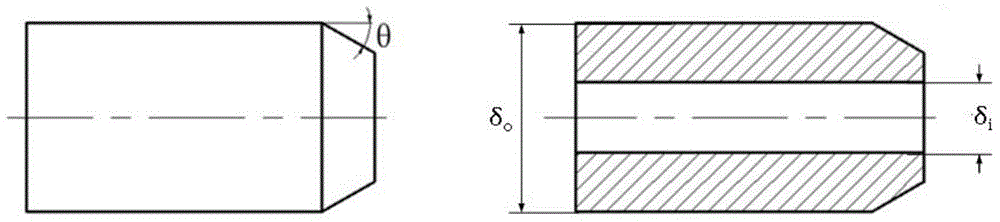

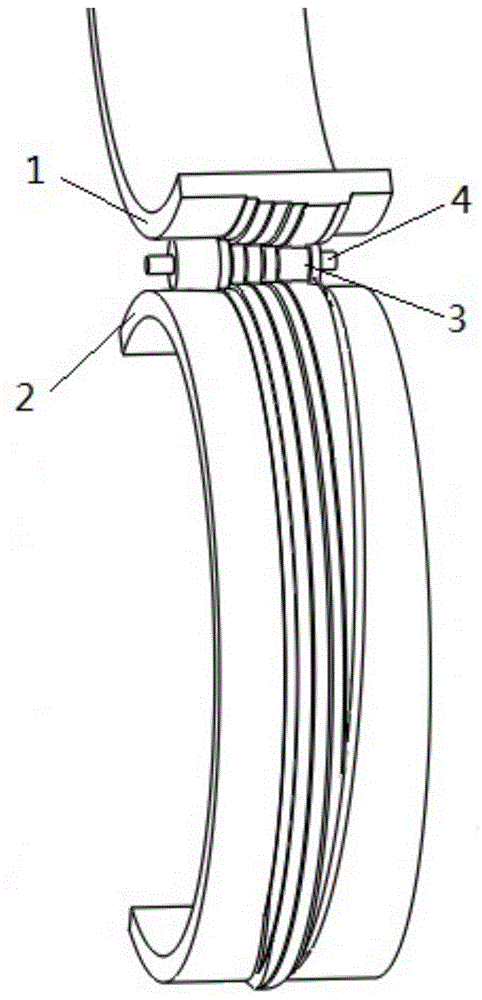

[0028] The rolling of the hollow casing of the automobile half shaft is completed by the cross wedge rolling forming process. Take a blank with a 30° cone angle at one end (such as figure 2 ) to 1000°C, penetrate the mandrel, the difference between the diameter of the mandrel 4 and the inner diameter of the billet is about 1mm, and send it into the two molds——between the upper roller and the lower roller through the axial pusher device. The billet with the mandrel makes a rotary motion under the action of the mold, and the rolled piece 3 is rolled into shape, such as image 3 shown. After forming, the rolled piece 3 is pushed out from between the two dies by the axial pusher device, and the mandrel 4 is pushed out to obtain Figure 6 The whole process of the shown hollow semi-shaft casing blank is completed on a cross wedge rolling mill and a pair of molds.

[0029] Figure 4 , Figure 5 It is the die expansion diagram and the groove diagram of the implementation example...

Embodiment 2

[0031] Using the cross wedge rolling forming process to complete the hollow casing of the automobile half shaft (such as figure 1 ) for rolling. Take a blank with a 25° cone angle at one end (such as figure 2 ) to 900°C, penetrate the mandrel, the difference between the diameter of the mandrel and the inner diameter of the billet is about 1 mm, and send it between the two molds through the axial pushing device. The billet with the mandrel makes a rotary motion under the action of the die, and the rolled piece is rolled into shape, such as image 3 shown. After the forming is completed, the rolled piece is pushed out from between the two dies by the axial pusher device, and the mandrel is ejected to obtain Figure 6 Hollow half shaft bushing blanks shown.

[0032] Figure 4 , Figure 5 It is the die expansion diagram and the groove diagram of the implementation example of the automobile semi-axle casing blank formed by cross wedge rolling. The diameter of the top circle...

Embodiment 3

[0034] Using the cross wedge rolling forming process to complete the hollow casing of the automobile half shaft (such as figure 1 ) for rolling. Take a blank with a 35° cone angle at one end (such as figure 2 ) to 1150°C, penetrate the mandrel, the difference between the diameter of the mandrel and the inner diameter of the billet is about 1 mm, and send it between the two molds through the axial pushing device. The billet with the mandrel makes a rotary motion under the action of the die, and the rolled piece is rolled into shape, such as image 3 shown. After the forming is completed, the rolled piece is pushed out from between the two dies by the axial pusher device, and the mandrel is ejected to obtain Figure 6 Hollow half shaft bushing blanks shown.

[0035] Figure 4 , Figure 5 It is the die expansion diagram and the groove diagram of the implementation example of the automobile semi-axle casing blank formed by cross wedge rolling. The diameter of the top circle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com