Tube bending device and tube bending method

A technology of bending device and bending roller, which is applied in the field of pipe bending device and pipe bending, can solve the problems of large-scale and cost-increasing, undisclosed bending processed pipes, and the scheme of applying torsion, etc., and achieves easy operation and maintenance, Realization of miniaturization, simplification, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

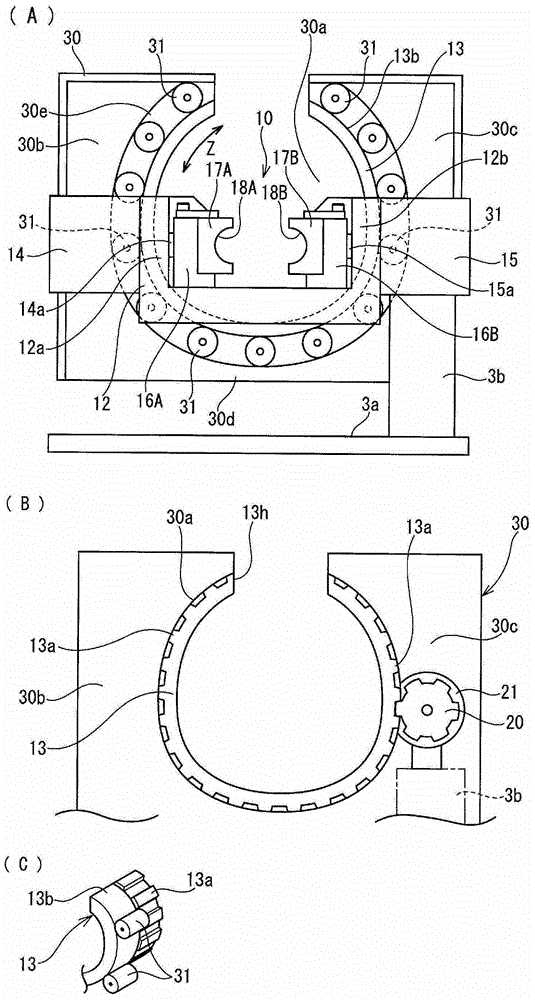

[0056] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

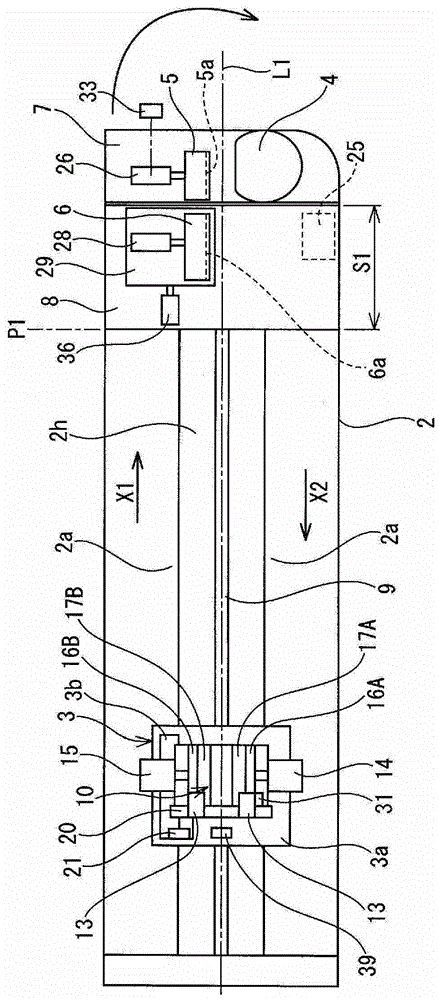

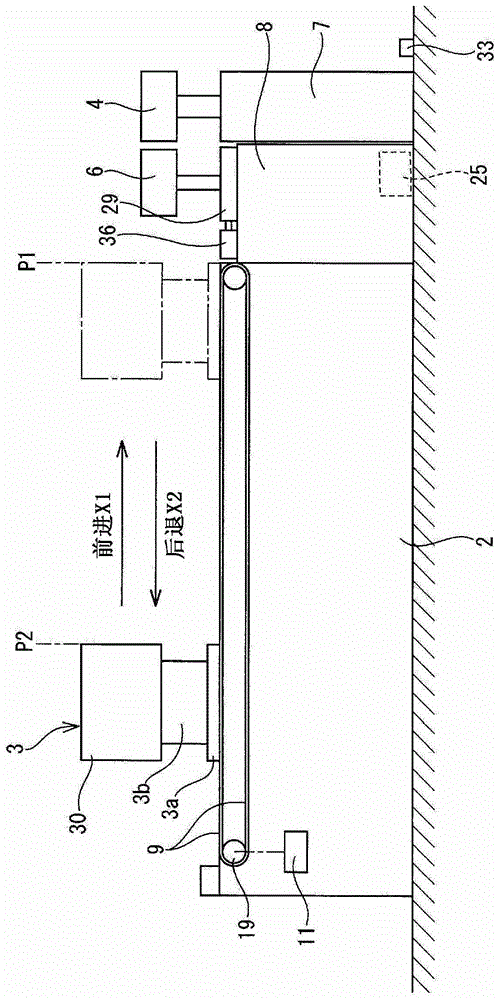

[0057] like figure 1 As shown, the overall structure of the bending device is provided with a conveyance path 2a along the longitudinal direction on the upper surface of the substantially rectangular shape of the base 2 fixed on the ground. The mobile trolley 3 mounted on the conveyance path 2a is advanced in the direction of the arrow X1 and stopped at the front end stop position P1, and the front end upper surface of the base 2 at a certain distance S1 from the front end stop position P1 is set to rotate. Free bending table 7, on the upper surface of the bending table 7, the bending roll mold 4 and the fastening mold 5 are arranged oppositely, and the pressure mold is arranged on the side between the bending table 7 and the front end stop position P1 6.

[0058] The mobile trolley 3 retreats from the front end stop position P1 in the direction of the arrow X2 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com