A rotary four-station clean grouting machine

A four-station, grouting machine technology, applied in the field of semi-solid metal processing, can solve the problems that are difficult to break through and have not made great breakthroughs in industrial applications, and achieve the effect of clean injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

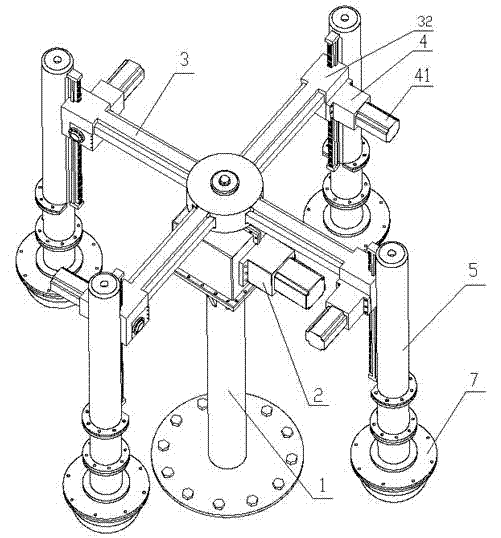

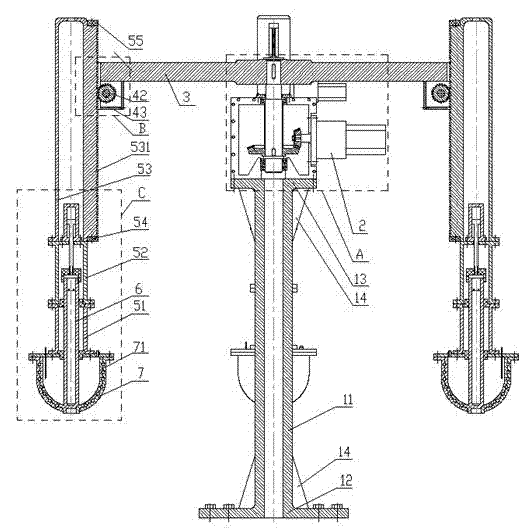

[0030] as attached figure 1 and 2 As shown, the rotary four-station clean grouting machine of the present invention mainly includes a frame 1, a rotary power assembly 2, a rotary support 3, and four sets of lifting and retrieving mechanisms.

[0031] Described frame 1 comprises main pillar 11, installation base 12 and installation platform 13 and is formed, and installation base 12 is fixed on the bottom of main pillar 11 by reinforcing rib 14, and it is fixed on required position by screw, and installation platform 13 is by reinforcing rib 14 is fixed on main pillar 11 tops.

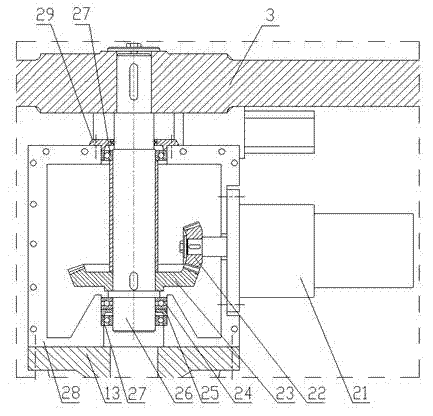

[0032]The rotary power assembly 2 includes a first servo drive motor 21, a deceleration support box 28 and an output shaft system. The first servo drive motor 21 is fixed on the side of the deceleration support box 28 and drives the slewing support 3 to rotate; The decelera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com