Ultrafine powder heavy bag packaging machine

A packaging machine and ultrafine powder technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problem of excessive dust and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

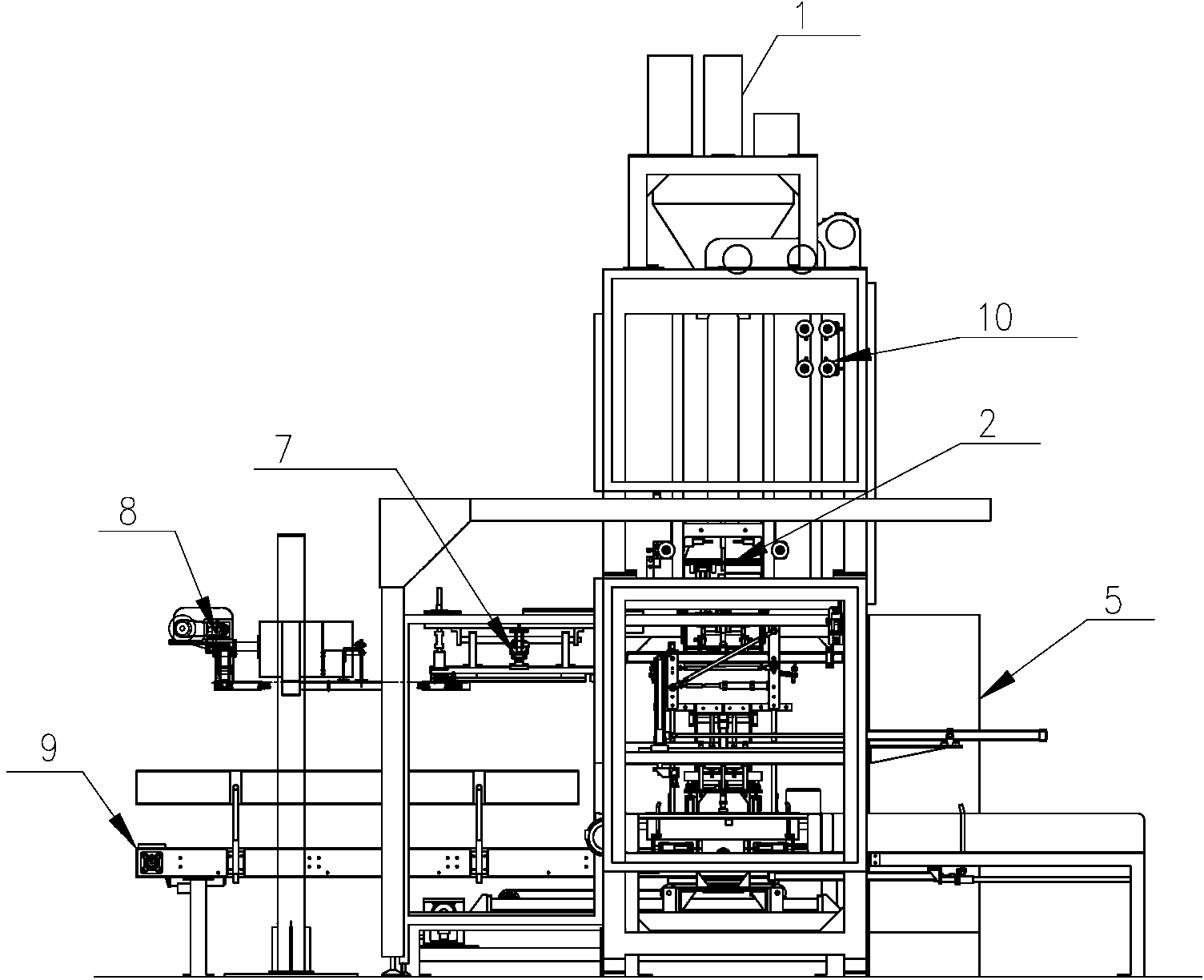

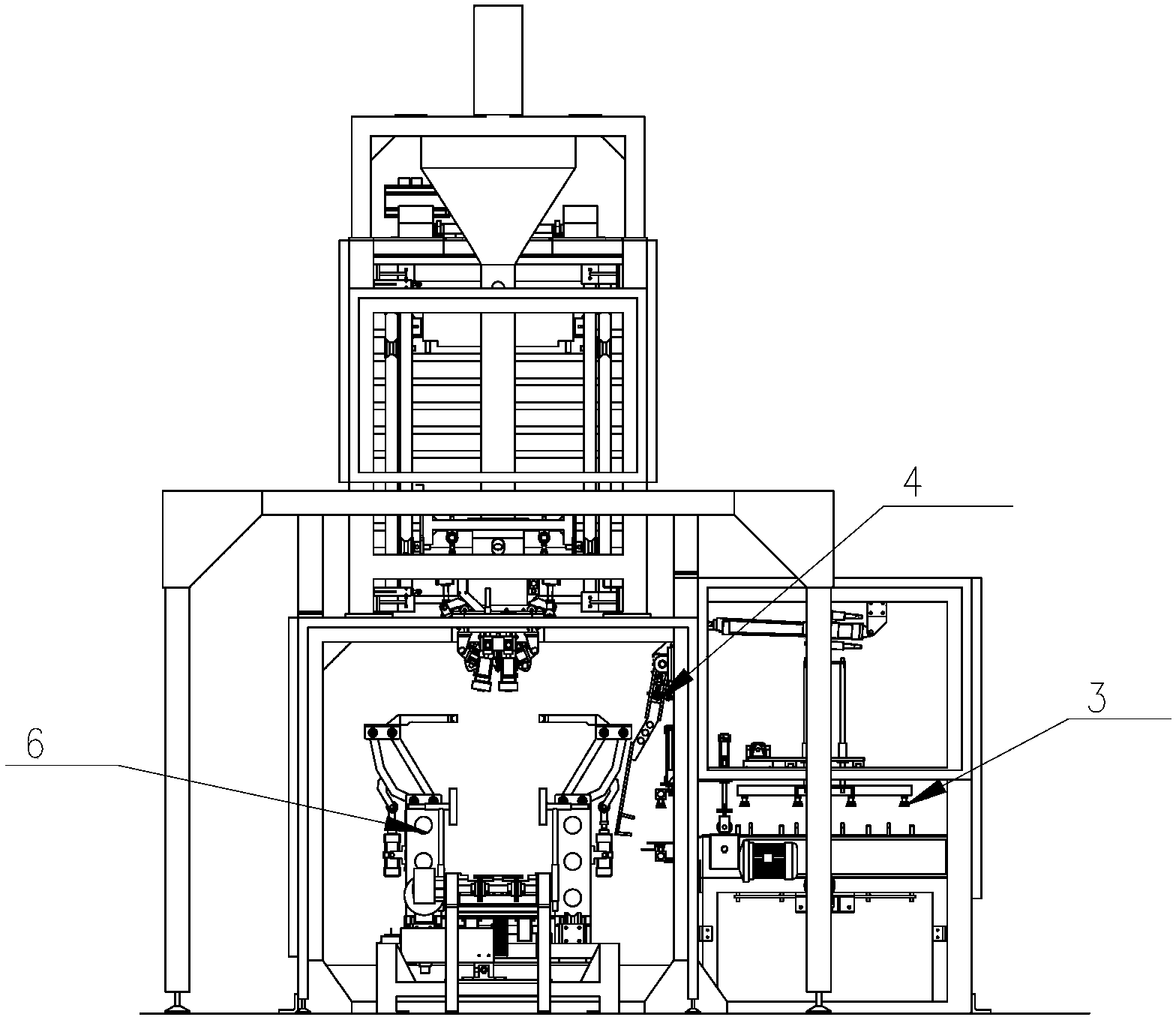

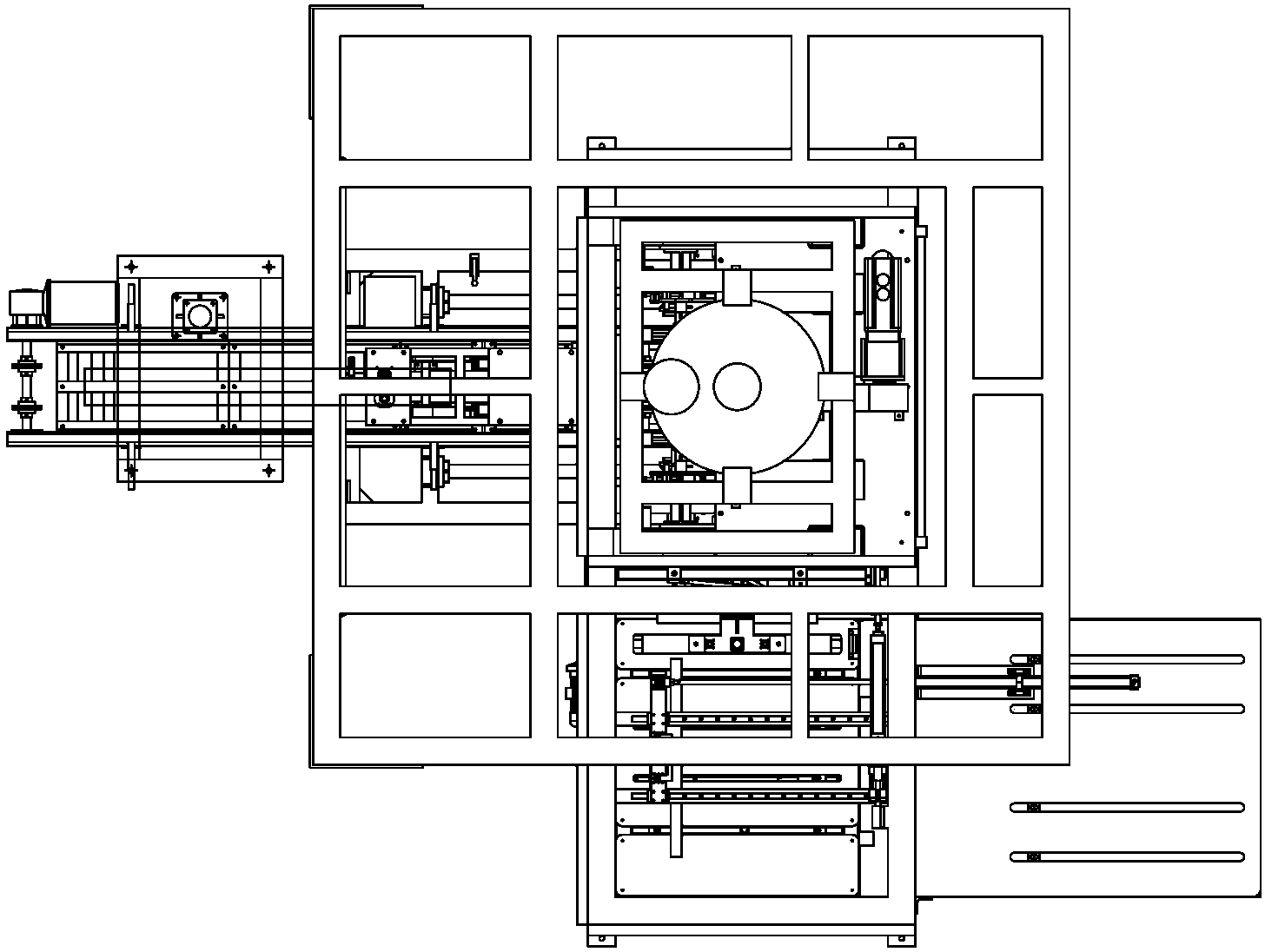

[0013] see figure 1 , 2 3. Ultrafine powder heavy bag packaging machine, including a frame, a vertical screw feeder 1 is installed on the upper part of the frame, a lifting bag carrying mechanism 2 is installed in the middle of the frame, and a bag picking mechanism 3 is installed on the right side of the frame , the upper bag manipulator 4 and the control cabinet 5, the bag holding mechanism 6 is provided below the lifting bag carrying mechanism 2, and the pocket guide mechanism 7, bag sewing machine 8 and sewing bag conveying line 9 are provided on the left side of the frame.

[0014] Lifting bag-carrying mechanism 2 includes a bag-carrying mechanism and a lifting mechanism. The bag-carrying mechanism is suspended directly below the discharge port of the powder packaging machine through a steel cable, and the steel cable bypasses the fixed position on the powder packaging machine. The pulley is connected with the lifting mechanism, and the bag carrying mechanism is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com