Method for connecting filter drum and built-in filter liner of water purifier in rotary inserting and rotary lifting manner, and built-in filter liner

A technology of water purifier and plug-in connection, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. It is difficult to popularize the device more widely, and the axial size is difficult to operate, so as to achieve the effect of simple and fast connection or separation operation, avoiding inconvenience and service expenses, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

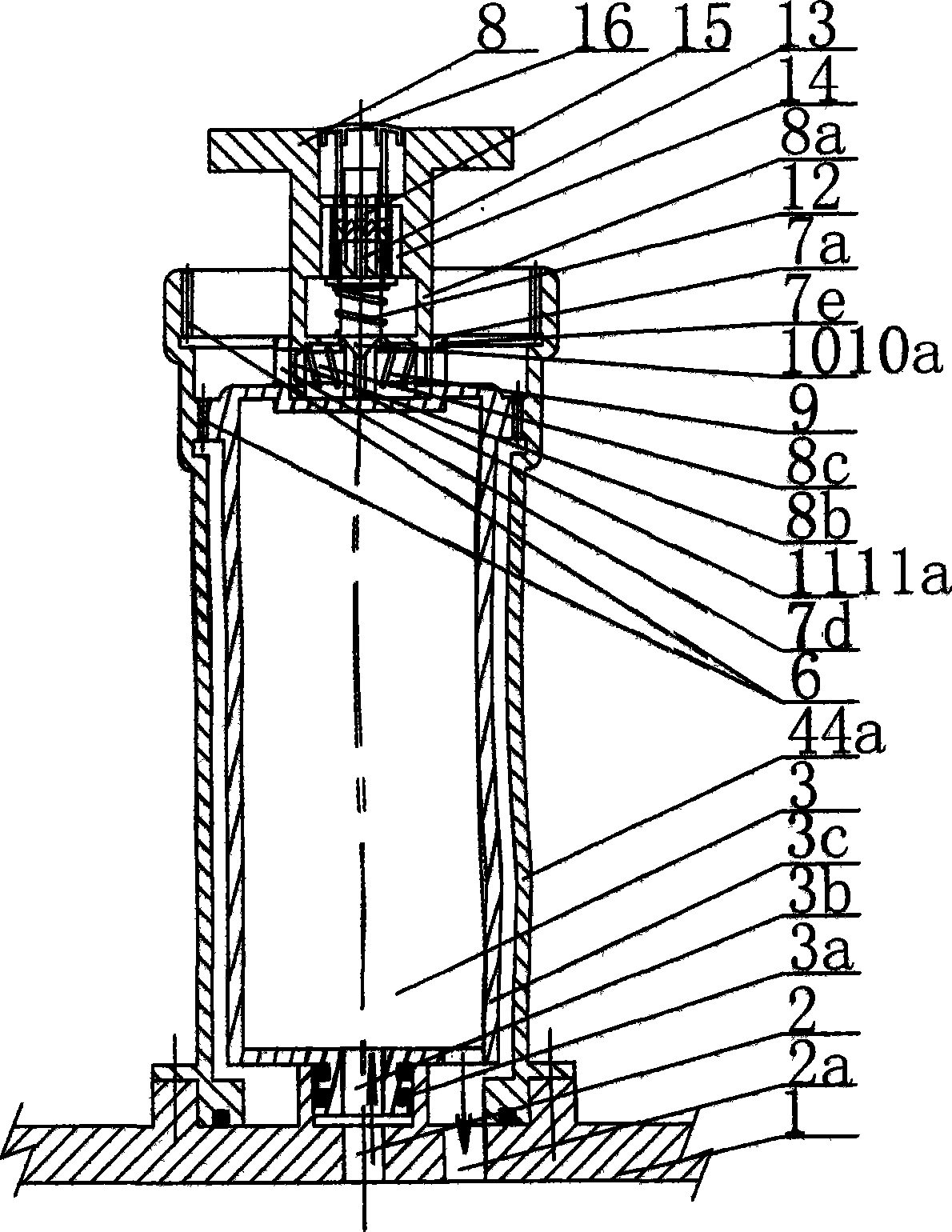

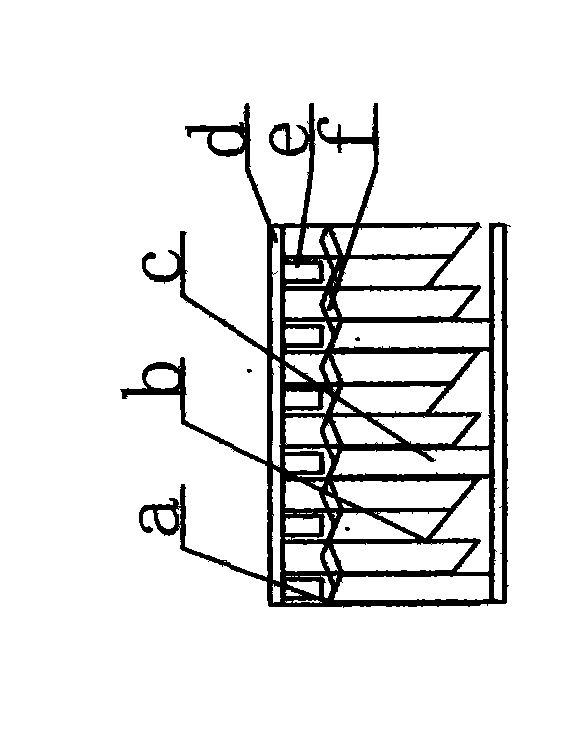

[0036] Example 1. figure 1 , 2 A preferred embodiment of the invention is shown.

[0037] When plugging in the built-in closed filter gall 3, the polygonal plug-in structure 7a provided on the lower bracket 8a of the handle mechanism 8 and the polygonal plug-in structure 7a of the externally convex member 7e of the built-in closed filter gall 3 are inserted into each other, and the radial holes of the two parts 7d and 8b also correspond to each other. Press the button 16 located in the center of the handle mechanism 8 to make the position switching gear lever 15 move downward along the axial guide groove of the one-way ratchet outer cover 14 fixed on the bracket 8a, and push the one-way ratchet which is in the incomplete engagement state f The swivel 13 also moves downwards accordingly until its ratchet tooth tip is completely engaged when it is lower than the lower end of the one-way ratchet overcoat 14: under the action of the upward rebound force of the locking spring 12,...

Embodiment 2

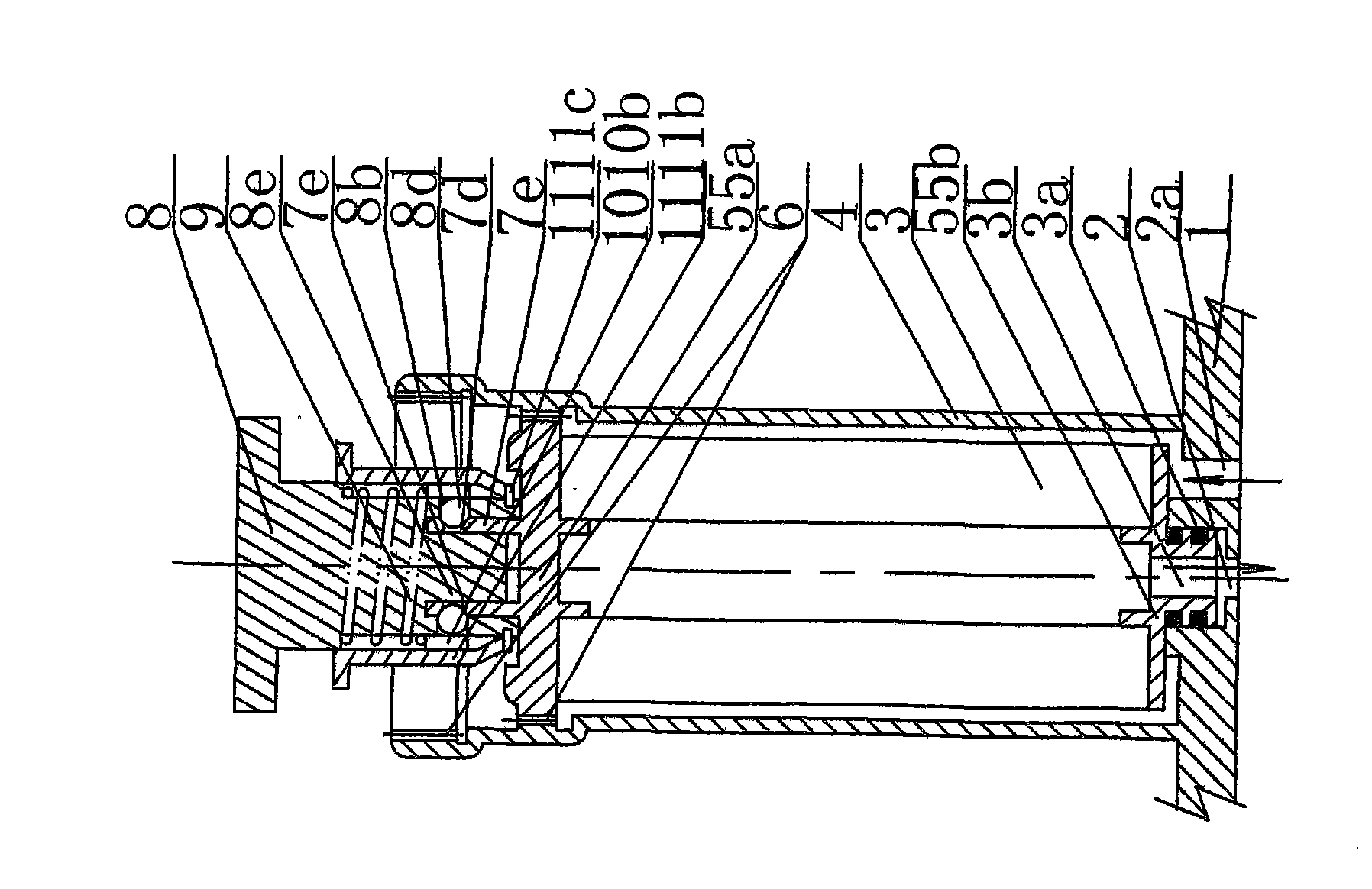

[0045] Example 2. image 3 A second embodiment of the invention is shown.

[0046] exist image 3 On the basis of the structure, when the built-in bare bladder 3 is plugged in, the limit sleeve 11b as the handle mechanism limiter 11 is pulled up, and the polygonal insertion structure 7a provided on the lower bracket 8e of the handle mechanism 8 is connected to the outside of the built-in bare bladder 3. The polygonal insertion structures 7a of the male member 7e are inserted into each other, and the radial holes 7d and 8b of the two parts also correspond to each other. The front end of the ball 8d located in the through hole 8b on the wall of the lower bracket 8e is pushed into the through hole of the lower bracket 8e when it encounters the protruding member 7e of the built-in bare bladder 3, and its rear end moves outward to the lower end of the push sleeve 10b and The reset position in the groove between the limit sleeves 11b. At this time, the handle mechanism 8 and the ...

Embodiment 3

[0050] Example 3. Figure 4 A third embodiment of the present invention is shown.

[0051] Figure 4 Among them, the one-piece filter cartridge 4 and the built-in bare tank 3 are connected and screwed together by a screw screw structure 6 . The top surface of the upper end cover 5a of the built-in bare bladder 3 is provided with an outwardly protruding member 7f with a threaded connection structure 7g. The lower bracket 8f of the handle mechanism 8 and the built-in naked bladder 3 are inserted into each other with the polygonal plug-in structure 7a. The handle mechanism 8 is also provided with a threaded connection piece 8g connected to the built-in bare bladder 3 threaded connection structure 7g. The threaded connector 8g is sleeved on the lower support 8f and can move up and down. The lower bracket 8f is inserted into the handle mechanism 8 and connected by a pin 8h to form a single body.

[0052] When inserting the built-in closed filter gallbladder 3, the polygonal pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com