Production method of mortar concrete admixture

A technology for mortar concrete and production methods, which is applied in the fields of organic chemistry, hydrolysis preparation, and halogen introduction preparation, etc., and can solve problems such as complicated process and difficult quality control and guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Embodiment 1: the production of mortar concrete admixture

[0092] The implementation steps of this embodiment are as follows:

[0093] A. Hydrolysis reaction

[0094] Using the analysis method described in this manual, the chemical composition of the distillation residue effluent obtained by Ningbo Huanyang Chemical Co., Ltd. during the production of dichloropropanol by the glycerol method was determined, and the results are listed in Table 4.

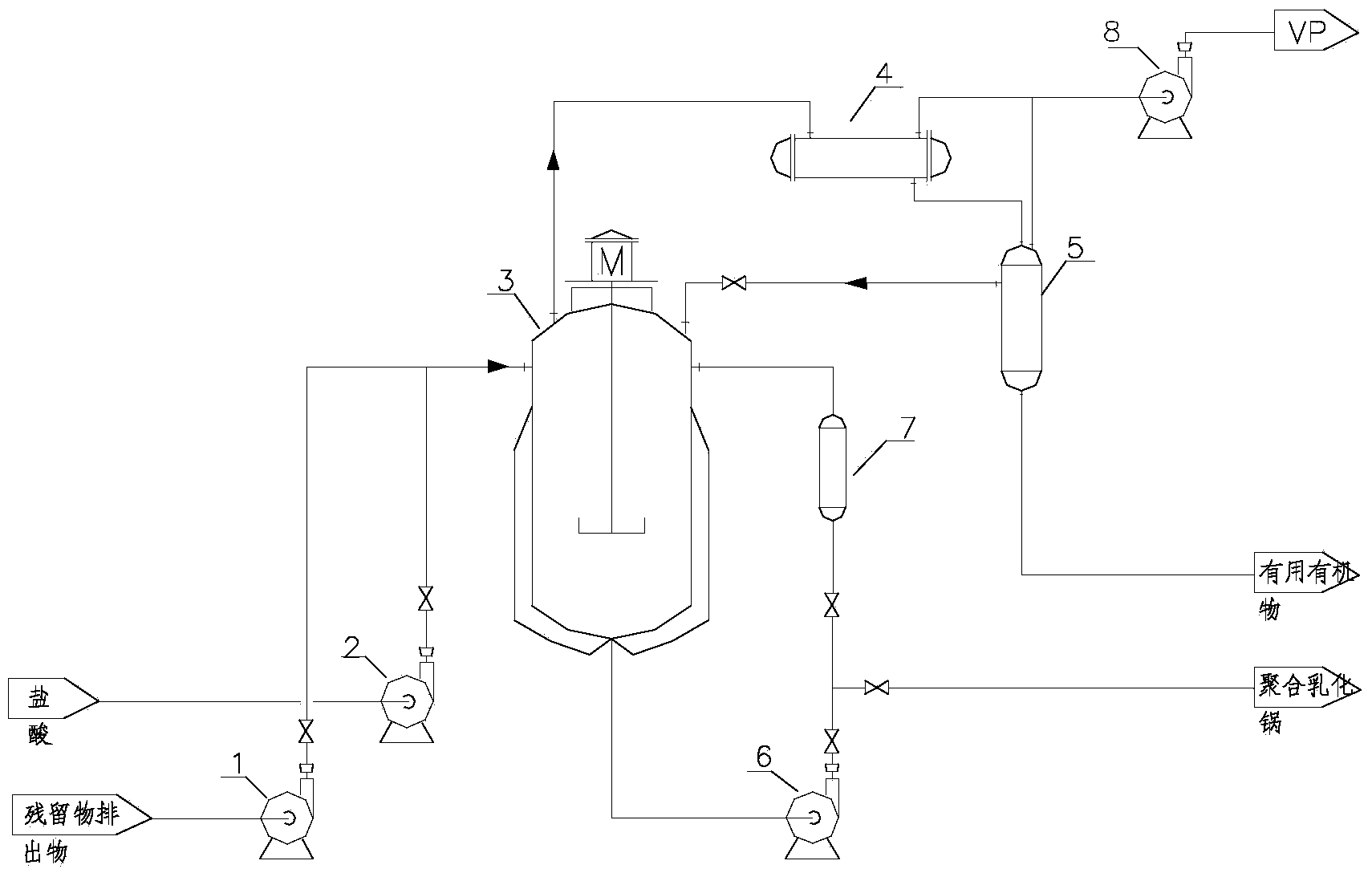

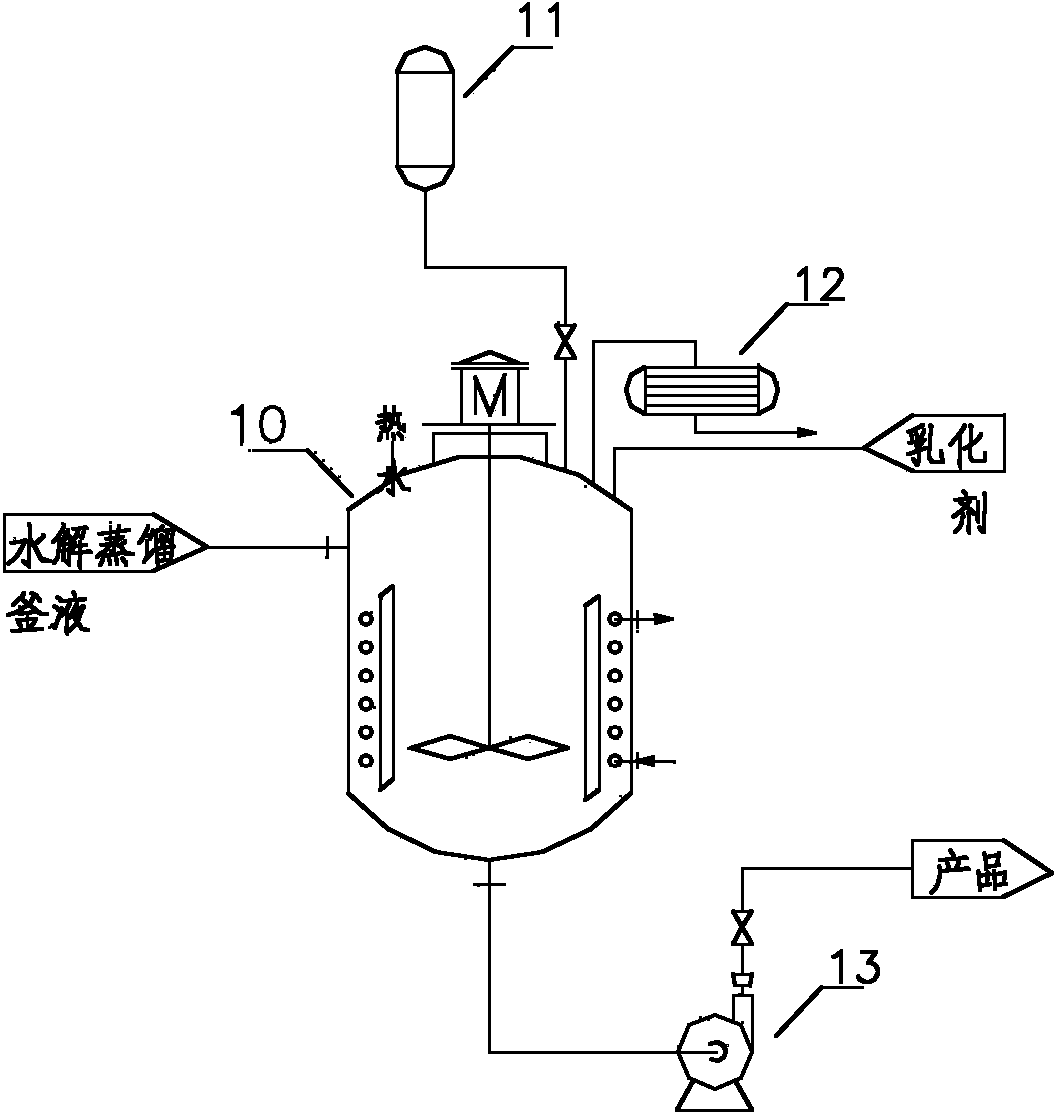

[0095] Let the said distillation residue effluent be sent to the hydrolysis reaction kettle 3 sold by Suzhou Fadell Glass-lined Equipment Co., Ltd. under the trade name glass-lined stirring vessel by the pipeline through the pump 1, and let the 13% hydrochloric acid aqueous solution by weight be The pipeline is sent to the above-mentioned hydrolysis reaction kettle 3 through the pump 2, and the distillation residue discharge and the hydrochloric acid aqueous solution are stirred according to their weight ratio of 1:0.54 at a t...

Embodiment 2

[0106] Embodiment 2: the production of mortar concrete admixture

[0107] The implementation steps of this embodiment are as follows:

[0108] A. Hydrolysis reaction

[0109] Using the analytical method described in this manual, the chemical composition of the distillation residue effluent obtained by Ningbo Huanyang Chemical Co., Ltd. during the production of dichloropropanol by the glycerol method was determined, and the results are listed in Table 5.

[0110] Let the said distillation residue effluent be delivered by pipeline through pump 1 in the hydrolysis reactor 3 sold by Shandong Taiji Glass-lined Equipment Co. Send it to the above-mentioned hydrolysis reaction kettle 3 through the pump 2, and the distillation residue discharge and the hydrochloric acid aqueous solution are in a weight ratio of 1:0.58, under the condition of stirring at a temperature of 110°C and an anchor stirring speed of 90r / min Carry out hydrolysis reaction 16h, this hydrolysis reaction material ...

Embodiment 3

[0119] Embodiment 3: the production of mortar concrete admixture

[0120] The implementation steps of this embodiment are as follows:

[0121] A. Hydrolysis reaction

[0122] Using the analysis method described in this manual, the chemical composition of the distillation residue effluent obtained by Ningbo Huanyang Chemical Co., Ltd. during the production of dichloropropanol by the glycerin method was determined, and the results are listed in Table 6.

[0123]Let the said distillation residue effluent be sent to the hydrolysis reactor 3 sold by Suzhou Fadell Glass-lined Equipment Co., Ltd. under the trade name glass-lined stirring vessel by the pipeline through the pump 1, and let 10% hydrochloric acid by weight The aqueous solution is sent to the above-mentioned hydrolysis reaction kettle 3 through the pump 2 through the pipeline, and the distillation residue discharge and the hydrochloric acid aqueous solution are stirred at a temperature of 112 ° C and an anchor stirring s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com