Superstrong ultraviolet-proof composite and manfucturing method thereof

A technology of anti-ultraviolet and composite materials, applied in the field of composite materials, can solve the problems such as the use of window stickers is not very wide, the service life of curtains is shortened, and the ultraviolet ray cannot be protected, so as to achieve industrialized large-scale production, good thermal insulation effect, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

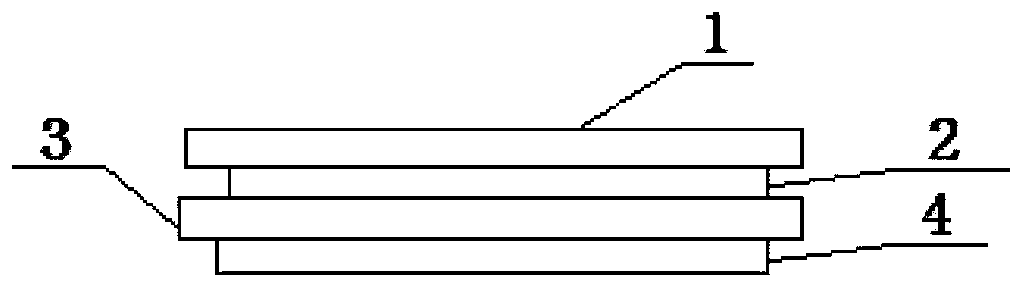

[0014] Such as figure 1 The super-strong anti-ultraviolet composite material shown is composed of bubble film 1, LDPE layer 2, self-adhesive 3, and PVC layer 4 from top to bottom.

[0015] The thickness of the bubble film 1 is 1.2mm; the thickness of the LDPE2 is 35um; the thickness of the PVC layer 4 is 32um.

[0016] The method for making the above-mentioned ultra-strong anti-ultraviolet composite material comprises the following steps:

[0017] a. Paste the self-adhesive 3 on the PVC layer 4;

[0018] b. Extrude LDPE at a temperature of 320-350° C., pour it between the air bubble film 1 and the self-adhesive 3 to bond the two together, and form the LDPE layer 2, which is the super-ultraviolet-resistant composite material.

Embodiment 2

[0020] Such as figure 1 The super-strong anti-ultraviolet composite material shown is composed of bubble film 1, LDPE layer 2, self-adhesive 3, and PVC layer 4 from top to bottom.

[0021] The thickness of the bubble film 1 is 0.4mm; the thickness of the LDPE2 is 20um; the thickness of the PVC layer 4 is 15um.

[0022] The method for making the above-mentioned ultra-strong anti-ultraviolet composite material comprises the following steps:

[0023] a. Paste the self-adhesive 3 on the PVC layer 4;

[0024] b. Extrude LDPE at a temperature of 320-350° C., pour it between the air bubble film 1 and the self-adhesive 3 to bond the two together, and form the LDPE layer 2, which is the super-ultraviolet-resistant composite material.

Embodiment 3

[0026] Such as figure 1 The super-strong anti-ultraviolet composite material shown is composed of bubble film 1, LDPE layer 2, self-adhesive 3, and PVC layer 4 from top to bottom.

[0027] The thickness of the air bubble film 1 is 2mm; the thickness of the LDPE2 is 50um; the thickness of the PVC layer 4 is 50um.

[0028] The method for making the above-mentioned ultra-strong anti-ultraviolet composite material comprises the following steps:

[0029] a. Paste the self-adhesive 3 on the PVC layer 4;

[0030] b. Extrude LDPE under the condition of 320-350°C, pour it between the air bubble film 1 and the self-adhesive 3 to make the two leached together to form the LDPE layer 2, which is the super-ultraviolet-resistant composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com