Postprocessing system control method, postprocessing electronic control unit and controller

A technology of electronic control unit and control method, which is applied in the direction of electric control of exhaust treatment device, diagnostic device of exhaust treatment device, exhaust treatment, etc., to achieve the effect of improving the efficiency of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

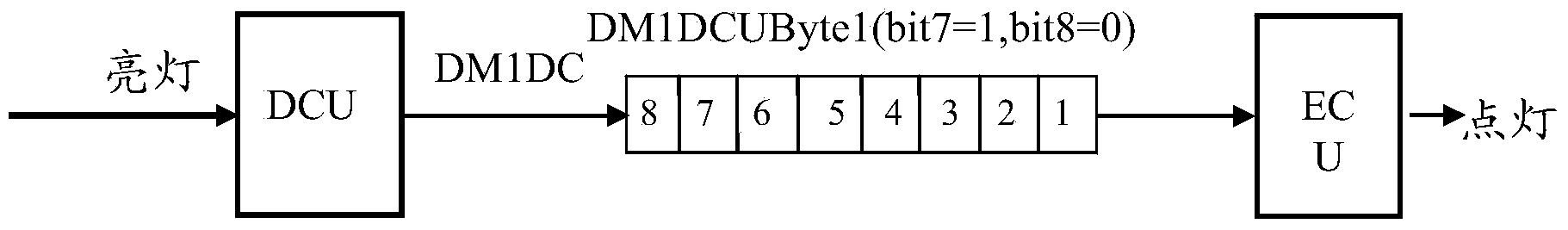

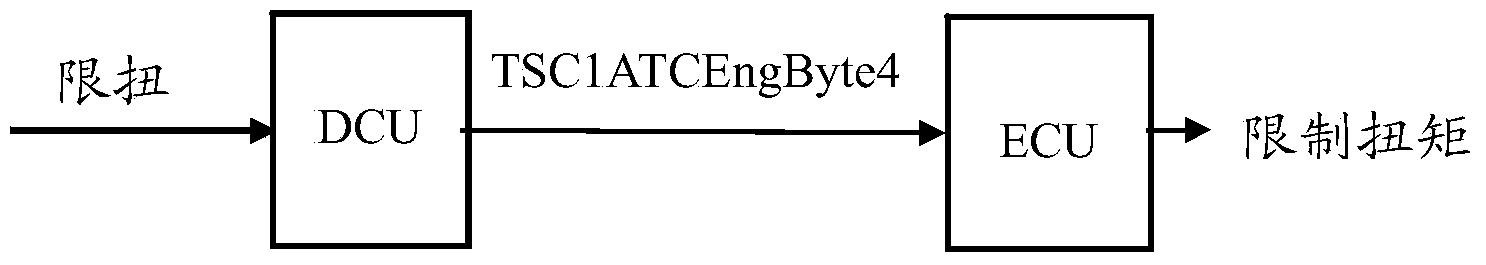

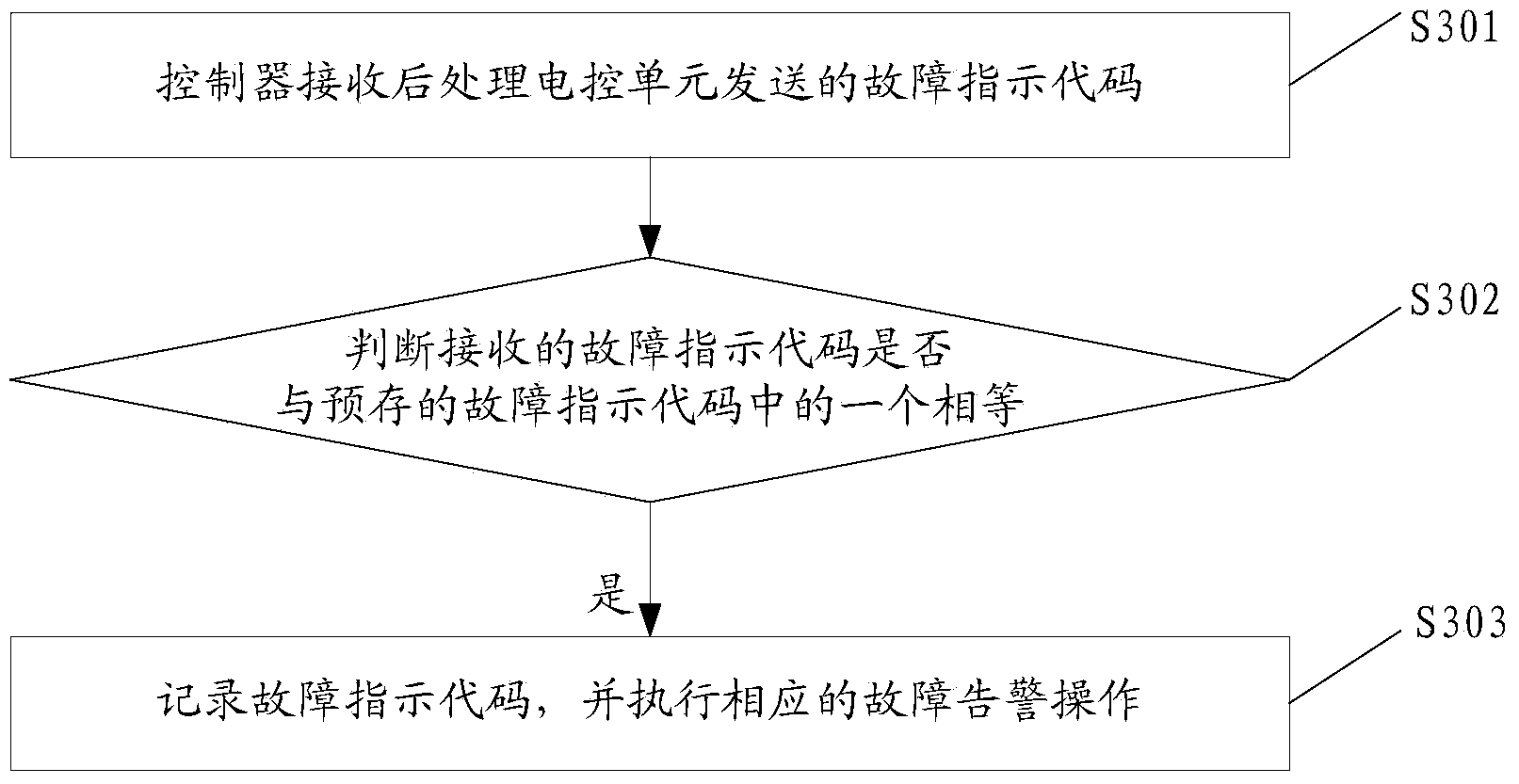

[0037] In the existing after-treatment system troubleshooting, when the after-treatment system fails and needs to be turned on and the torque is limited, the service personnel connect to the ECU through INCA (a kind of engine calibration software) to check the fault management memory (DSM) to determine the specific fault At this time, since the fault is not reported in the fault management system (DSM) of the ECU, the service personnel cannot immediately confirm that it is a fault in the post-processing system, resulting in low efficiency in fault elimination and fault repair. The control method of the post-processing system provided by the present invention, the post-processing electronic control unit and the controller can find out the fault point in time by setting the fault code, and then repair the fault point to improve the repair efficiency. In the following, a method for controlling an aftertreatment system provided by the present invention will firstly be introduced in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com