Multifunctional integrated valve

An integrated valve body technology, applied in the field of integrated valves and water outlet pipelines after water pumps, can solve problems such as cumbersome installation, large space occupation, and mutual impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

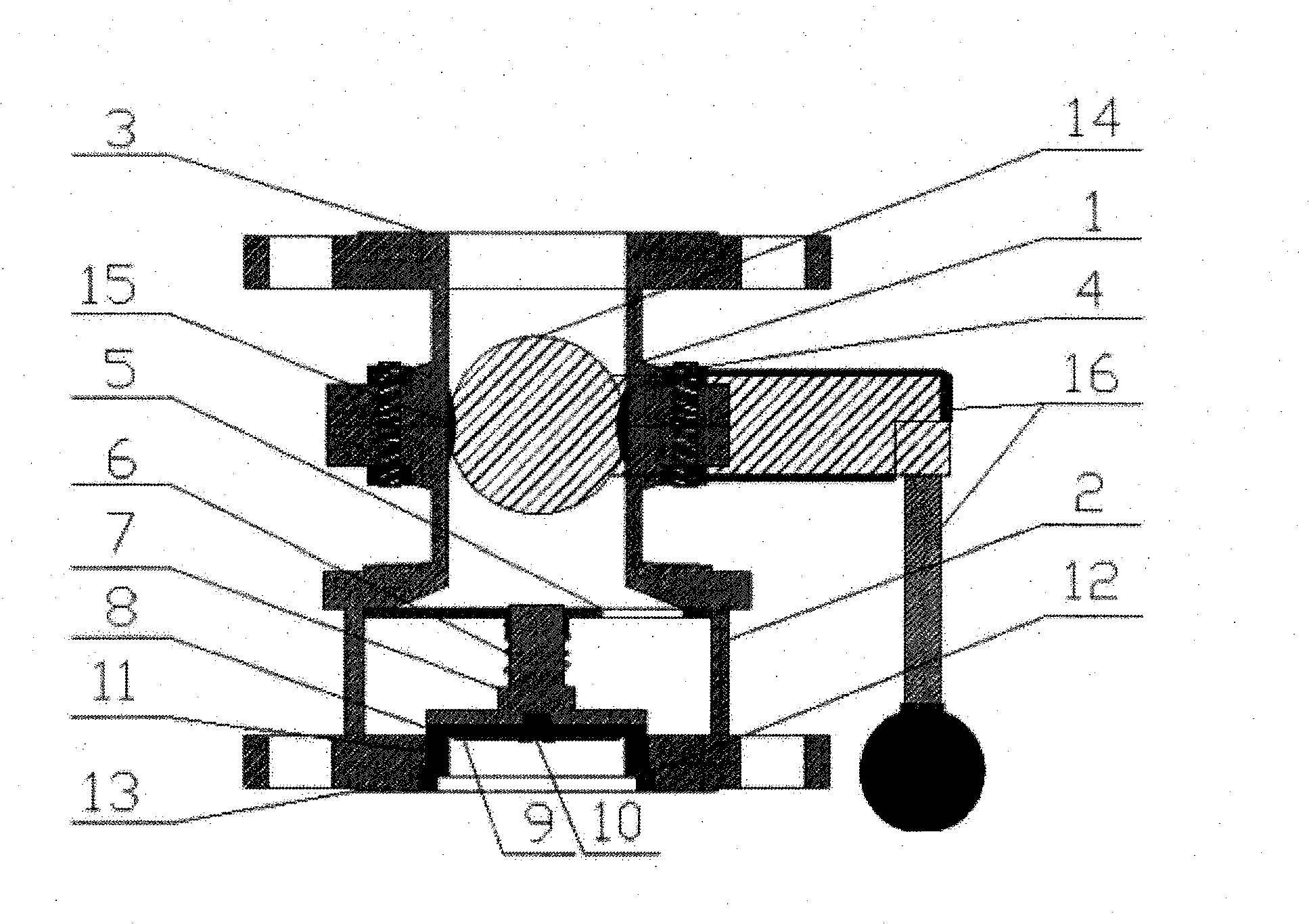

[0007] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0008] As shown in the figure, the valve is integrated, the upper and lower valve bodies (1), (2) are connected by connecting bolts (4), the upper and lower flanges (3), (13) are connected to the pipeline, and the lower flange (13) is threaded structure, the rotatable bonnet (11) is connected with it through threads, and the rotatable bonnet (11) can be opened to inspect and repair the check valve core (7). The check valve core (7) is built into the lower valve Inside the body (2), the contact part between the check valve spool (7) and the rotatable bonnet (11) is lined with a silicone gasket (8), between the check valve spool (7) and the positioning plate (5) Equipped with spring (6). Through the handle and connecting rod (16), the opening and closing of the valve disc (14) can be operated, and the connecting bolt (4) can be loosened to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com