Cleaning head device and on-line cleaning robot of condenser

A technology for cleaning robots and cleaning heads, which is applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc. It can solve the problems of high accuracy requirements for cleaning nozzles and cooling pipes, reduce equipment material resources, facilitate mobile positioning, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

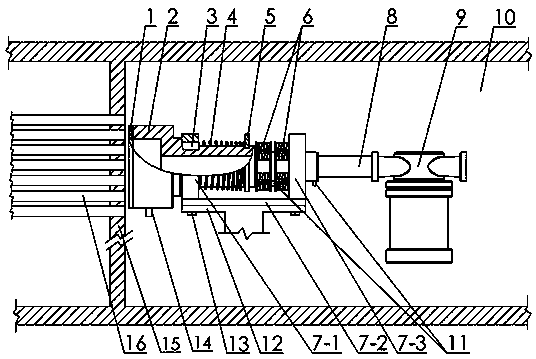

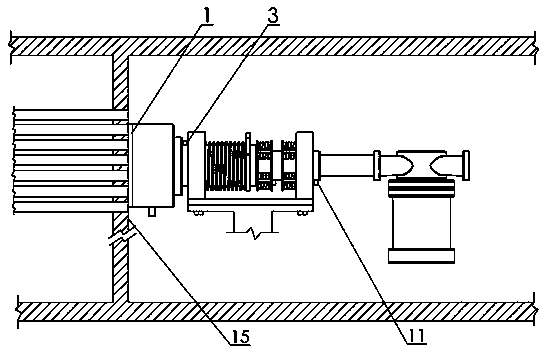

[0024] figure 1 A specific embodiment of the present invention is introduced, a cleaning head device and an online cleaning robot with a cleaning head device are introduced in detail, figure 1 It is shown that in the non-cleaning state, the online cleaning robot is in a non-contact state with the condenser tube sheet.

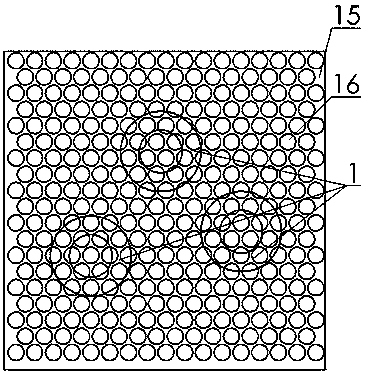

[0025] The cleaning head device is composed of a sealing gasket 1, a cleaning nozzle 2, a mechanical arm connection device, a return spring 4, and an electrified solenoid 6. Among them: the cleaning nozzle 2 is a combination of large and small pipe diameters, the front end is the front straight pipe of the large diameter end, the rear end is the rear end straight pipe of the small diameter end, and the large diameter end is based on the cooling pipe 16 on the condenser tube plate 15 The array is selected as a circle or a square or a rhombus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com