Electric equipment control circuit applied to supersonic combustion test

A technology of supersonic combustion and electrical equipment, applied in electrical program control, chemical analysis using combustion, program control in sequence/logic controllers, etc. and other issues to achieve the effect of ensuring the safety of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

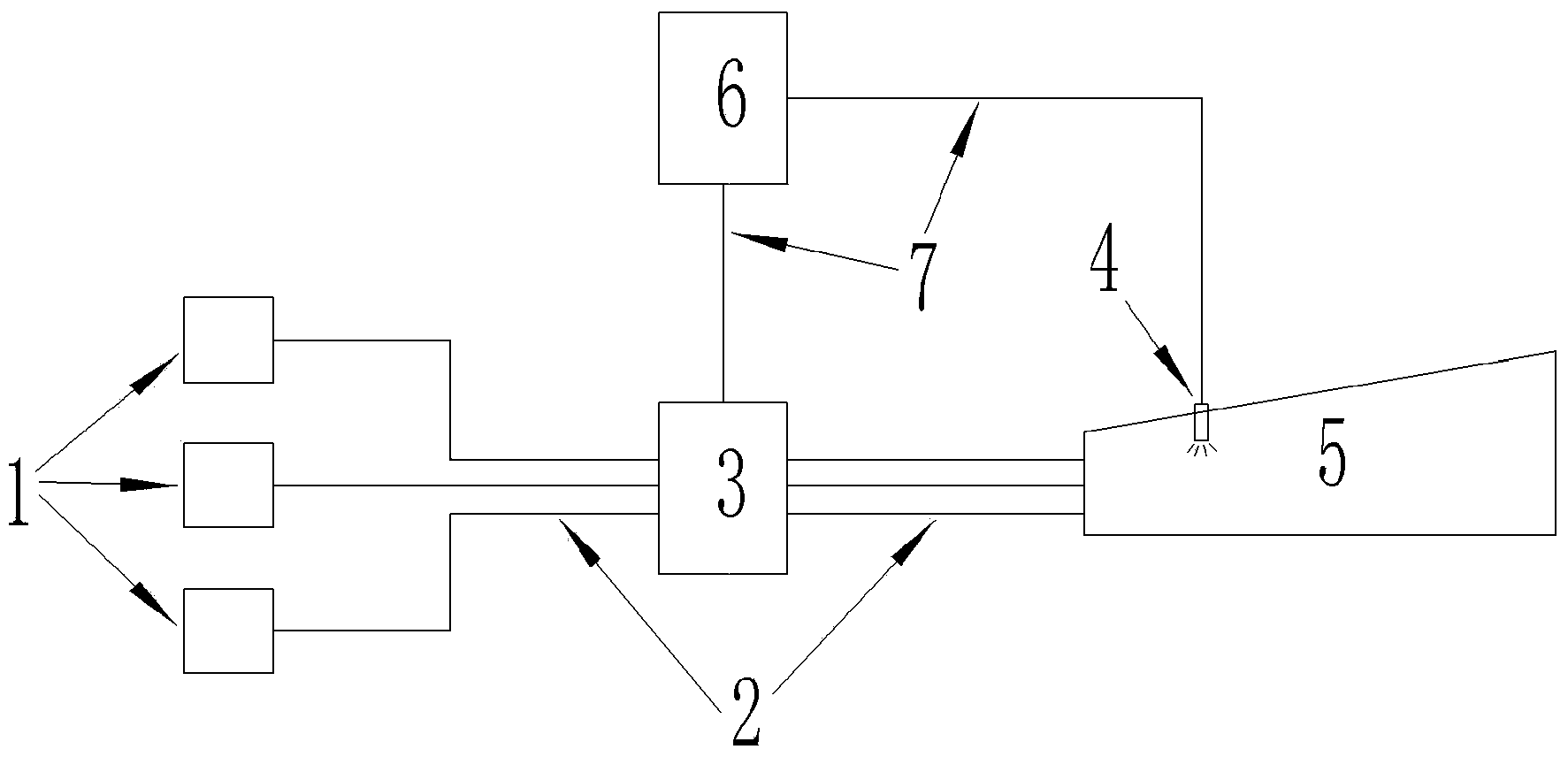

[0040] In order to facilitate the description of this set of control circuits, first a brief introduction is made to the main systems of the supersonic combustion test, such as figure 1shown. Various high-pressure gases and liquids used in the experiment are stored in the high-pressure storage tank 1, such as air, oxygen, hydrogen, ethylene, and aviation kerosene. The gas or liquid in these storage tanks is transported into the supersonic combustion chamber 5 through various high-pressure pipelines 2 . In the experiment, by controlling various valves and pump equipment 3 and the igniter 4, the gas and liquid enter the supersonic combustion chamber 5 in a certain order, ignite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com