A Method of Improving the Accuracy of Steel Coil Weight Calculation

A technology of calculating precision and steel coil, applied in the direction of calculation, special data processing applications, instruments, etc., can solve the problems of increasing processing workload and time, inability to accurately calculate strip length, unstable speed measurement, etc., to reduce processing work. measure, improve the accuracy of calculations, and address the effects of being overweight or underweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Set the coiled strip thickness to 2mm and width to 1250mm, when the measured Pj value is 256, when the measured Pzl value is 853:

[0030] D. j =1.89×400× =1.89×400× ≈2519mm

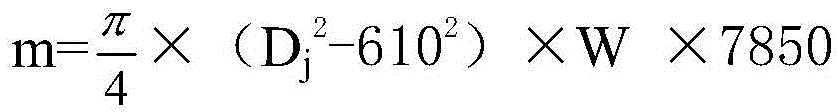

[0031] Steel coil weight m= ×(D j 2 -610 2 )×W×7850

[0032] = ×(2.519 2 -0.610 2 )×1.250×7850

[0033] ≈46034 kg.

Embodiment 2

[0035] Set the thickness of the coiled strip to 0.7mm and the width to 1250mm, use a new steering roll, K is 1.033, when the measured value of Pj is 256, and when the value of Pzx is 462:

[0036] D. j =K×1.64×600× =1.033×1.64×600× ≈1776mm

[0037] Steel coil weight m= ×(D j 2 -610 2 )×W×7850

[0038] = ×(1.776 2 -0.610 2 )×1.250×7850

[0039] ≈21441 kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com