Fixing device for transmission electron microscope samples

A technology for electron microscopes and fixtures, applied in circuits, discharge tubes, electrical components, etc., and can solve problems such as flat-blade screws, lost samples, and dropped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

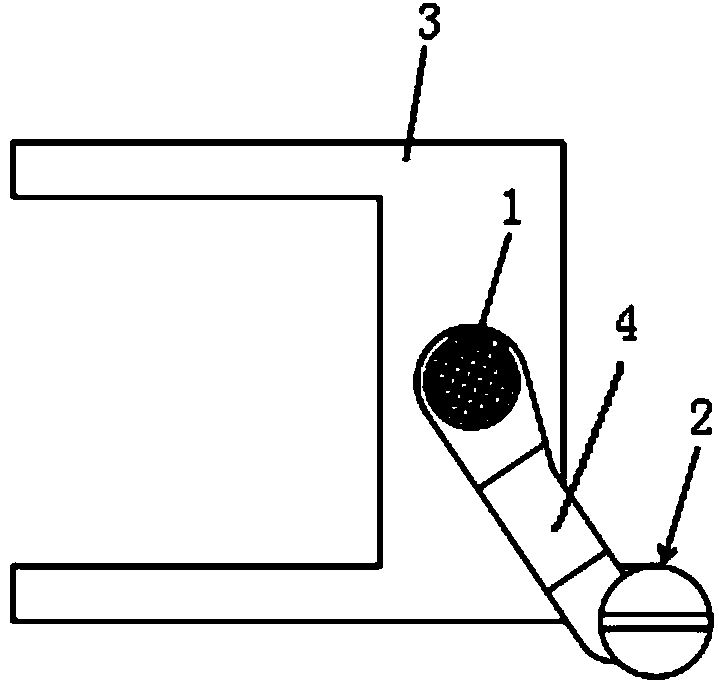

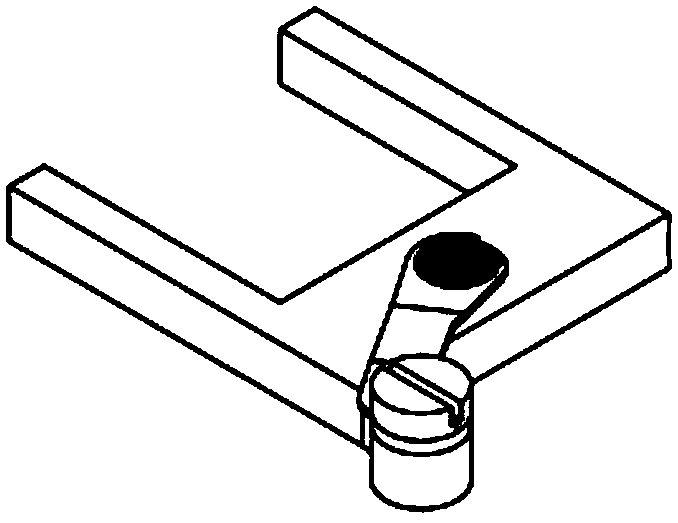

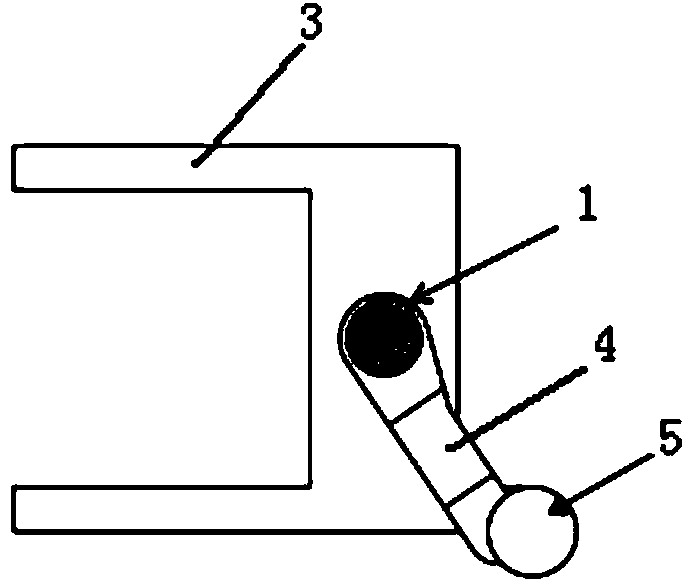

[0017] see Figure 2a , 2b as well as image 3 , the fixing device of the transmission electron microscope sample involved in the present invention includes: a sample rod 3 for carrying the sample 1, a spring screw 5 fixedly connected to the sample rod 3, and a shrapnel 4, and the spring screw 5 passes through The first end of the elastic piece 4 . The spring screw 5 has a locked state and a released state. When the spring screw 5 is in the locked state, the second end of the shrapnel 4 abuts against the sample 1. At this time, the spring of the spring screw 5 itself The pressure is transmitted to the shrapnel, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com