Heater for electrically heating cigarettes

A technology for electrically heating cigarettes and heaters, applied in the field of low-temperature cigarettes, can solve the problems of insufficient immediacy, complex heater manufacturing process, low heating efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

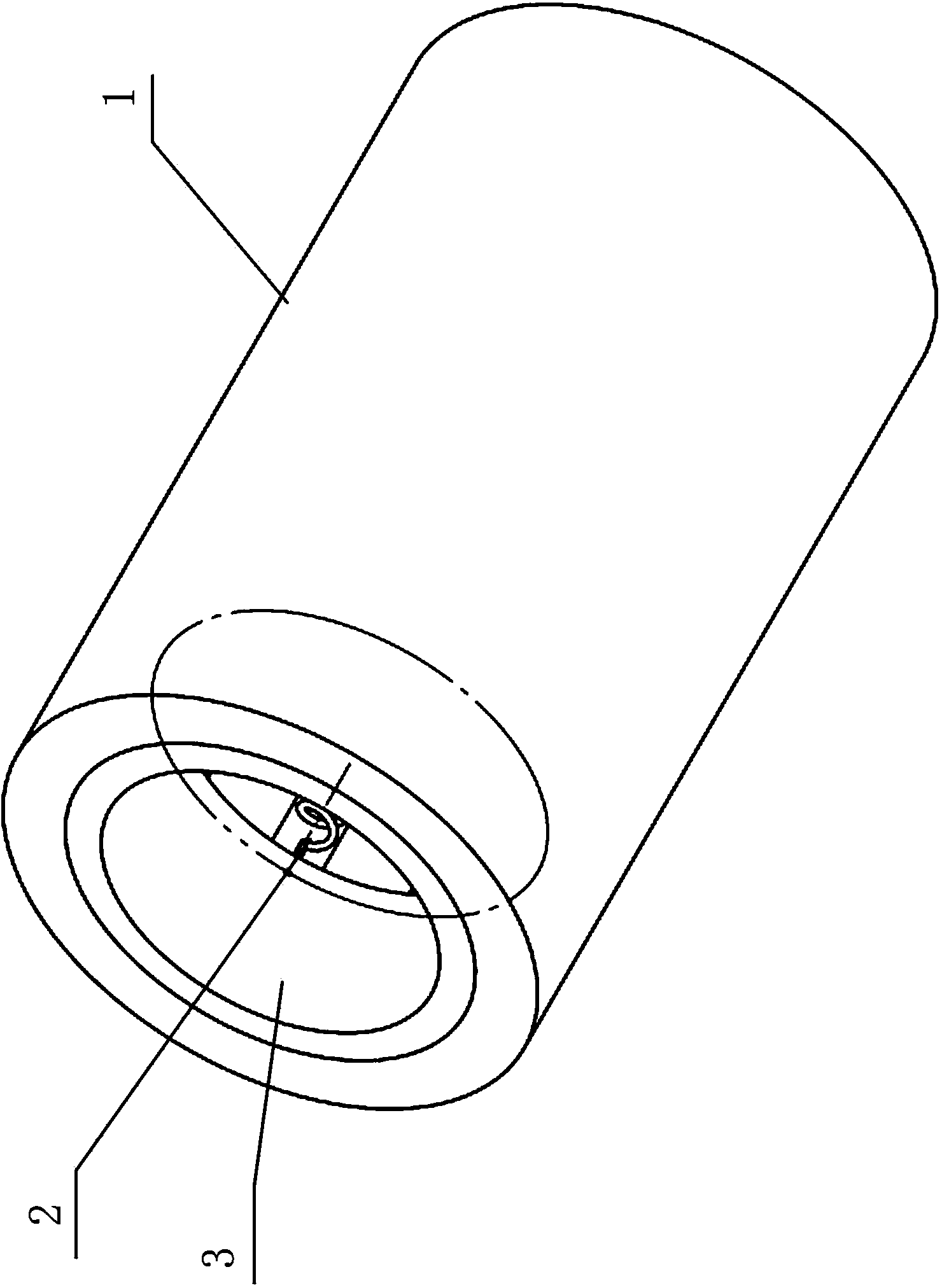

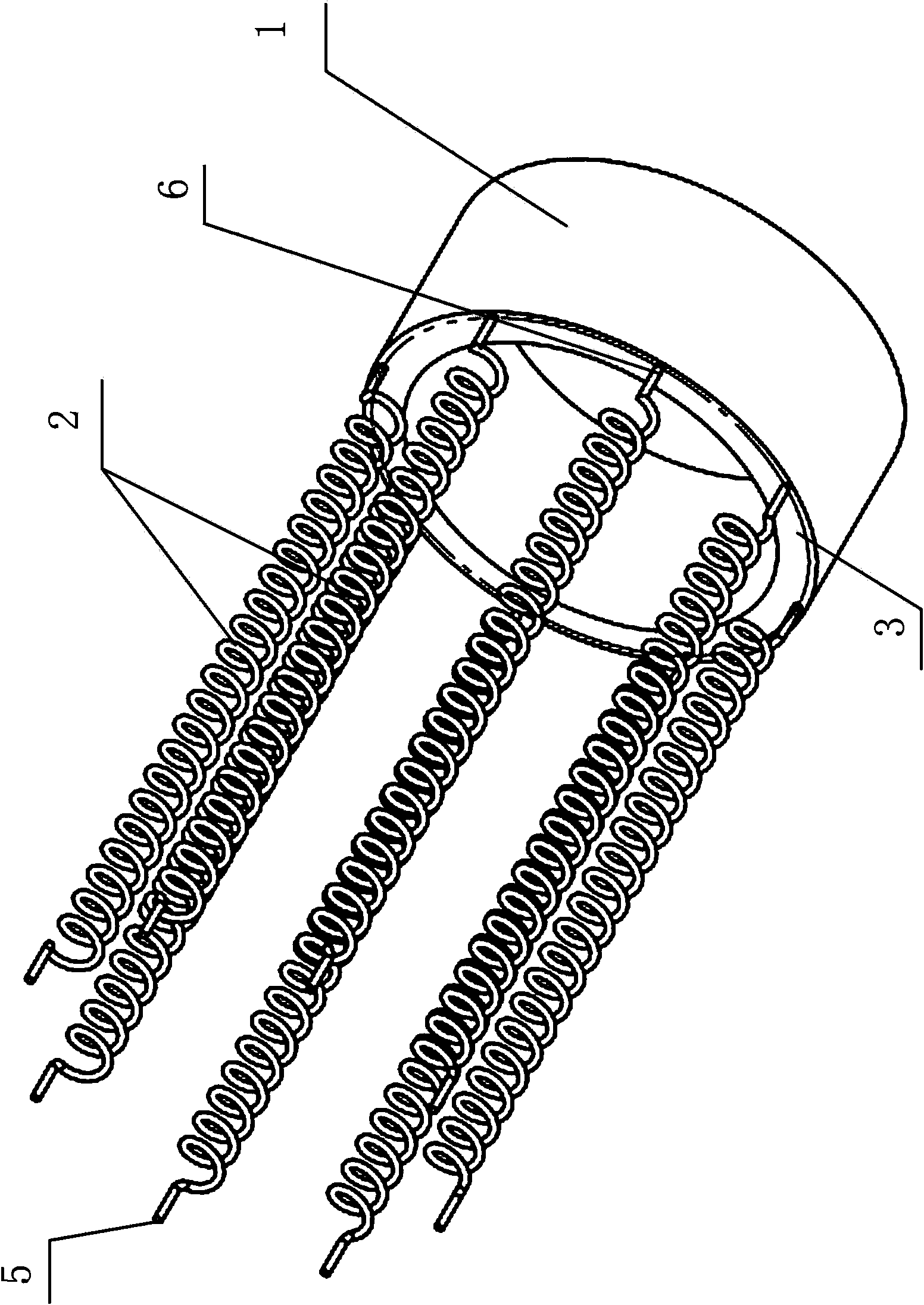

[0023] The heater of the present invention is composed of a housing 1 made of insulating material, several independent resistance heating wires 2 fixed inside the housing, and a common terminal 3 connected to each resistance heating wire 2. The conductive material is composed of three parts, each resistance heating One end of each resistance heating wire 2 is connected to the common terminal 3, and the other end of each resistance heating wire 2 is connected to one pole of the power supply through the control system switch. The common terminal is a conductive material, and the end of the common terminal 3 is connected to the power supply.

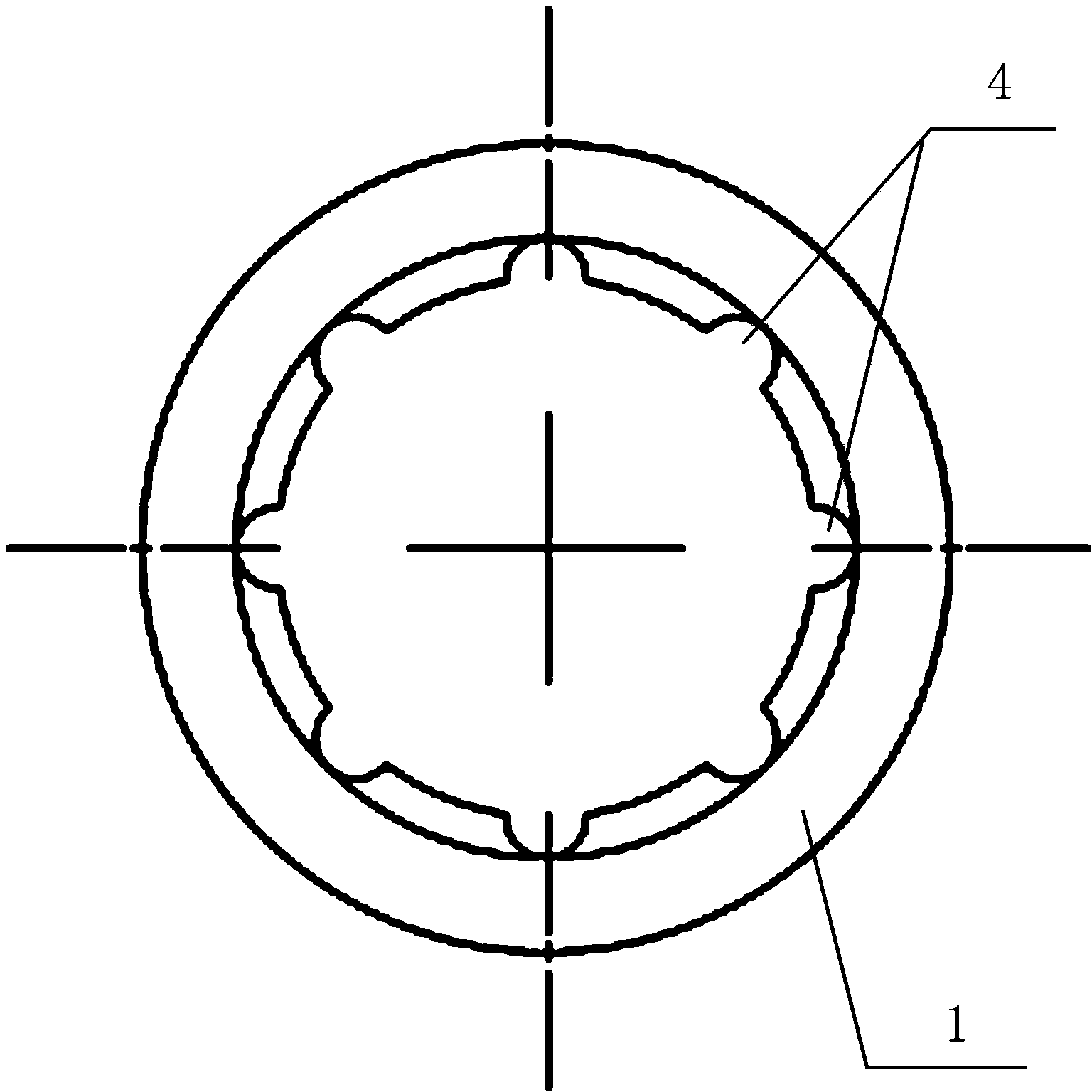

[0024] The shape of the resistance heating wire is polygonal, circular spiral or Great Wall.

[0025] The number of resistance heating wires 2 in each heater is 4-16, and the optimal number is 8. Each resistance heating wire 2 is arranged at the same interval and evenly distributed in the groove 4 on the inner wall of the insulating shell. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com