Angle-adjustable machining tool

A technology for mechanical processing and angle adjustment, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of waste of resources, unsightly appearance, space occupation, etc., reduce enterprise costs, improve production efficiency, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

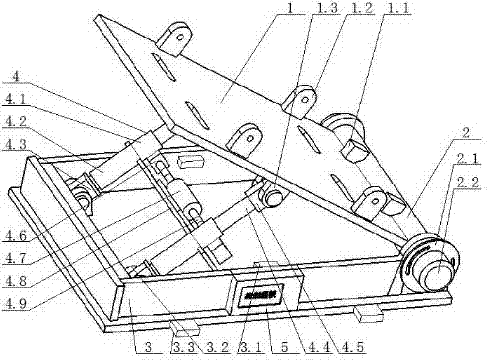

[0022] Such as figure 1 As shown, the angle-adjustable machining tooling includes a top plate 1, a hinge 2, a support body 3, an angle adjustment device 4, and an electrical control system 5 (the following descriptions all take the direction of the hinge as the front).

[0023] The top plate 1 is a flat plate structure, on which there are threaded holes and waist-shaped holes for installing the pressure plate bolts, and a supporting plate 1.1 perpendicular to the upper surface is provided at the edge lateral position of the front end of the upper surface of the top plate 1, and the supporting plate 1.1 can be used for positioning The workpiece can be used as a benchmark for processing at the same time. The lower surface of the top plate 1 is provided with two left and right symmetrical hinged ear seats I1.3.

[0024] One end of the hinge 2 is connected to the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com