Method for preparing m-xylylenediamine from m-phthalodinitrile through hydrogenation

A technology for producing m-xylylenediamine and isophthalonitrile, which is applied in the field of nitrile hydrocarbon hydrogenation, can solve the problems of unsatisfactory product selectivity, large amount of catalyst, high temperature or pressure, and achieves improvement of reaction operation period, prolongation of Longevity and effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Using aluminum sol with a solid content of 5% alumina as the carrier precursor, keep the temperature of the sol at 40 o c. Dissolve nickel nitrate in an appropriate amount of water to obtain a 0.5 g / ml nickel salt solution. Add an appropriate amount of nickel salt solution and ammonium molybdate alkaline solution with a molybdenum content of 4 wt.% to the aluminum sol to adjust the pH of the nickel-aluminum sol to ~9. o After aging for 24 hours at C, the gel was filtered, washed and dried to obtain the corresponding catalyst precursor. catalyst precursor at 100 o C roasting for 1 hour, 200 o C roasting 2h, 450 o C was calcined for 4 hours to obtain the oxidized catalyst, which was recorded as catalyst 1~3. The physical and chemical properties of the catalysts are listed in Table 1.

[0015]

Embodiment 2

[0017] Using aluminum sol with a solid content of 5% alumina as the carrier precursor, keep the temperature of the sol at 40 o c. Add a certain amount of cerium nitrate hexahydrate directly to the aluminum sol and stir for 1 hour. Dissolve nickel nitrate in an appropriate amount of water to obtain a 0.5 g / ml nickel salt solution. Add an appropriate amount of nickel salt solution and molybdenum content of 4wt.% ammonium molybdate alkaline solution to the sol, adjust the nickel aluminum sol pH ~ 9, at 90 o After aging for 24 hours at C, the gel was filtered, washed and dried to obtain the corresponding catalyst precursor. catalyst precursor at 100 o C roasting for 1 hour, 200 o C roasting 2h, 450 o C was calcined for 4 hours to obtain an oxidized catalyst, which was designated as catalyst 4. The physical and chemical properties of the catalysts are listed in Table 1.

[0018]

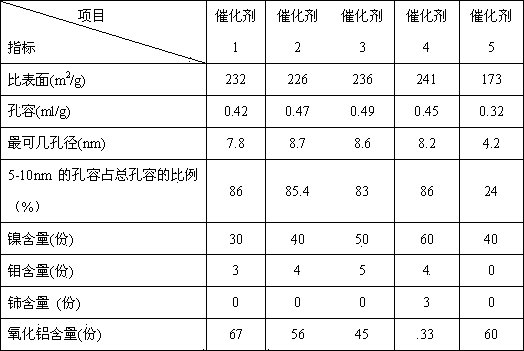

[0019] Table 1 Main physicochemical properties of catalysts 1-5

[0020]

Embodiment 3

[0025] Catalyst 1 is packed in the 80ml adiabatic bed hydrogenation reactor, and the reduction process condition that adopts is: in hydrogen atmosphere, under the pressure 0.2MPa condition, with 40 o The rate of C / h raises the temperature of the bed to 250 o C and maintained for 5h, then 10 o C / h heat up to 380 o C, maintain 10h, and then use 10 o C / h heat up to 450 o C, maintained for 12h, then cooled to the reaction temperature.

[0026] The reaction process conditions are: methanol / toluene / triethylamine is used as the reaction solvent, the reaction pressure is 7MPa, the inlet temperature is 70 o C, raw material space velocity 1.5h -1 Under the condition of running 300h. The conversion rate of isophthalonitrile is 100%, and the average selectivity of m-xylylenediamine is 95%.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com