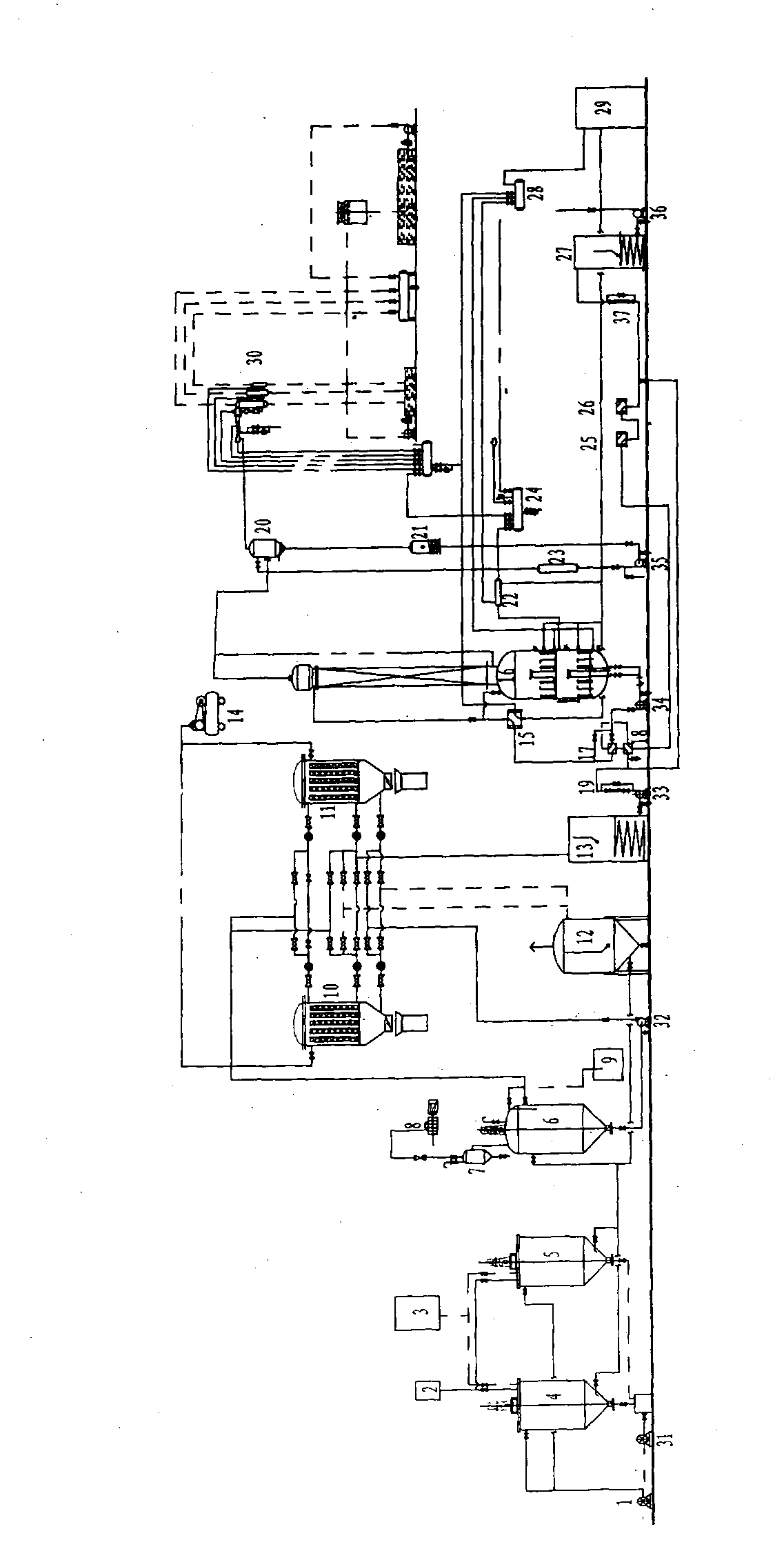

High-class animal oil refining process

A crude oil and clear oil technology, applied in the direction of fat oil/fat refining, essential oil/spice, fat production, etc., can solve the problems of inability to guarantee oil quality, long production cycle and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The operation process of the oil refining equipment: the crude oil is pumped into the water washing pot 4 or 5 with the pump 1, and phosphoric acid and soft water are added for degumming and chelating operations. When the oil and the oil foot are obviously separated and sink rapidly, stop stirring, let it stand for a certain period of time, release the oil foot, and then suck the clear oil to the decolorization tank 6. The oil foot is put into the oil foot barrel 38 from the bottom emptying pipe. When the oil foot contains a lot of oil, stop draining the oil foot. The oil foot is pumped into the oil foot tank by the pump 31, and mixed with the remaining oil in the washing tank into the next tank Continue to wash and chelate. The clear oil transferred in the water washing tank is removed to the decolorization tank 6 for adsorption and decolorization, and the vacuum water ring pump 8 passes through the liquid foam trap 7, so that the decolorization tank 6 reaches a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com