Method for removing fishy smell of deep sea fish oil

A deep-sea fish oil and fishy smell technology, which is applied in the direction of edible oil/fat, fat oil/fat refining, fat production, etc., can solve the problems of unsuitable fish oil, short storage period, fishy smell, etc., to overcome the incomplete removal of fishy smell, Overcome high cost and save solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

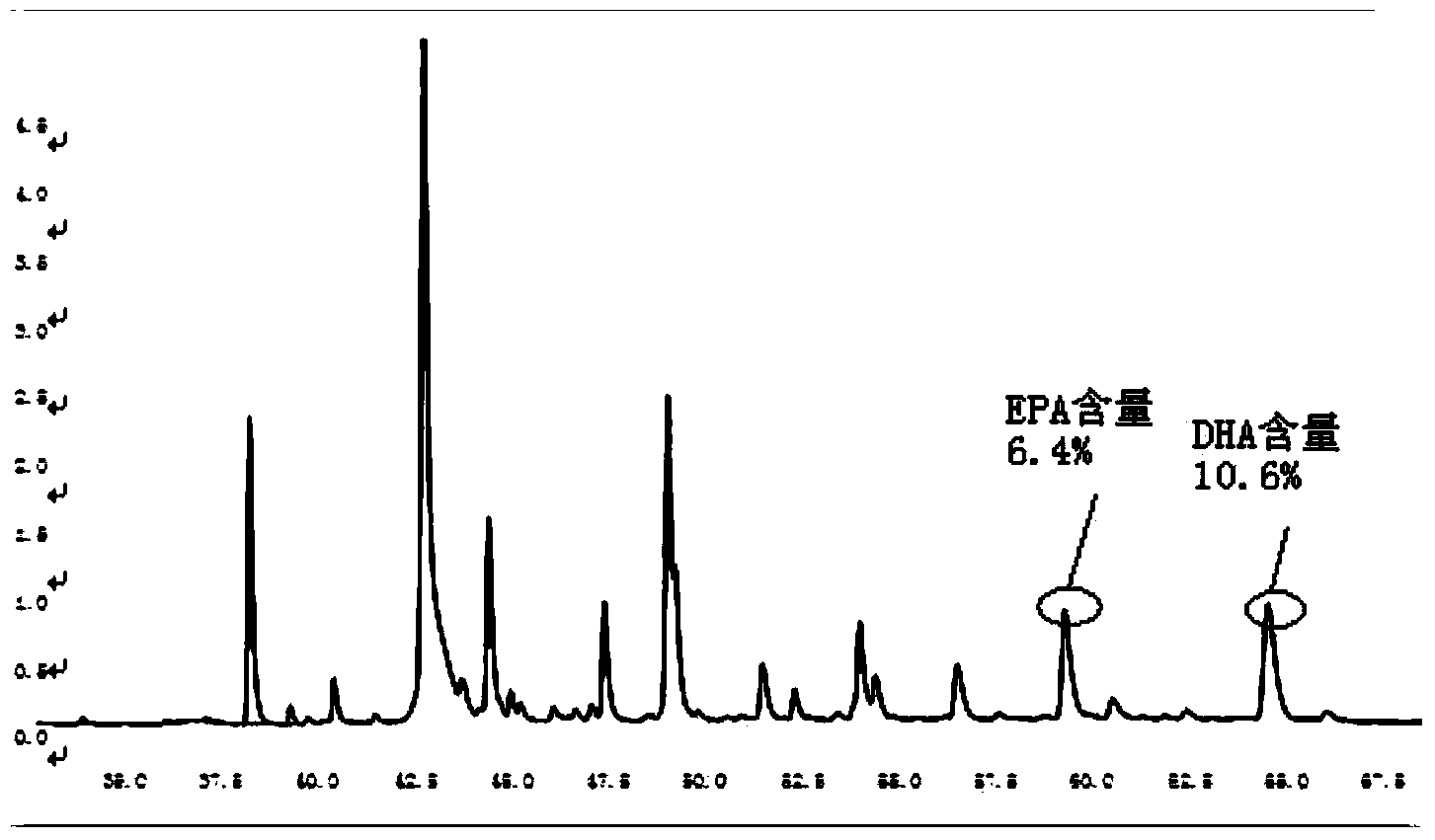

[0028] After degumming, deacidification, decolorization and deodorization, the refined deep-sea fish oil with 19% EPA and DHA content is put into the hydrogenation reactor, 0.2% by mass nickel catalyst is added, and the reaction is performed at a reaction temperature of 160°C and 0.3MPa React under pressure and stirring rate of 400r / min for 30 minutes to obtain lightly hydrogenated deep-sea fish oil; after the reaction, the lightly hydrogenated fish oil will be decolorized at 80°C for 30 minutes with 3% by mass activated clay and molecular distillation. Deodorized fish oil products that are completely odorless, and the content of EPA and DHA is determined to be 17%, see figure 1 .

Embodiment 2

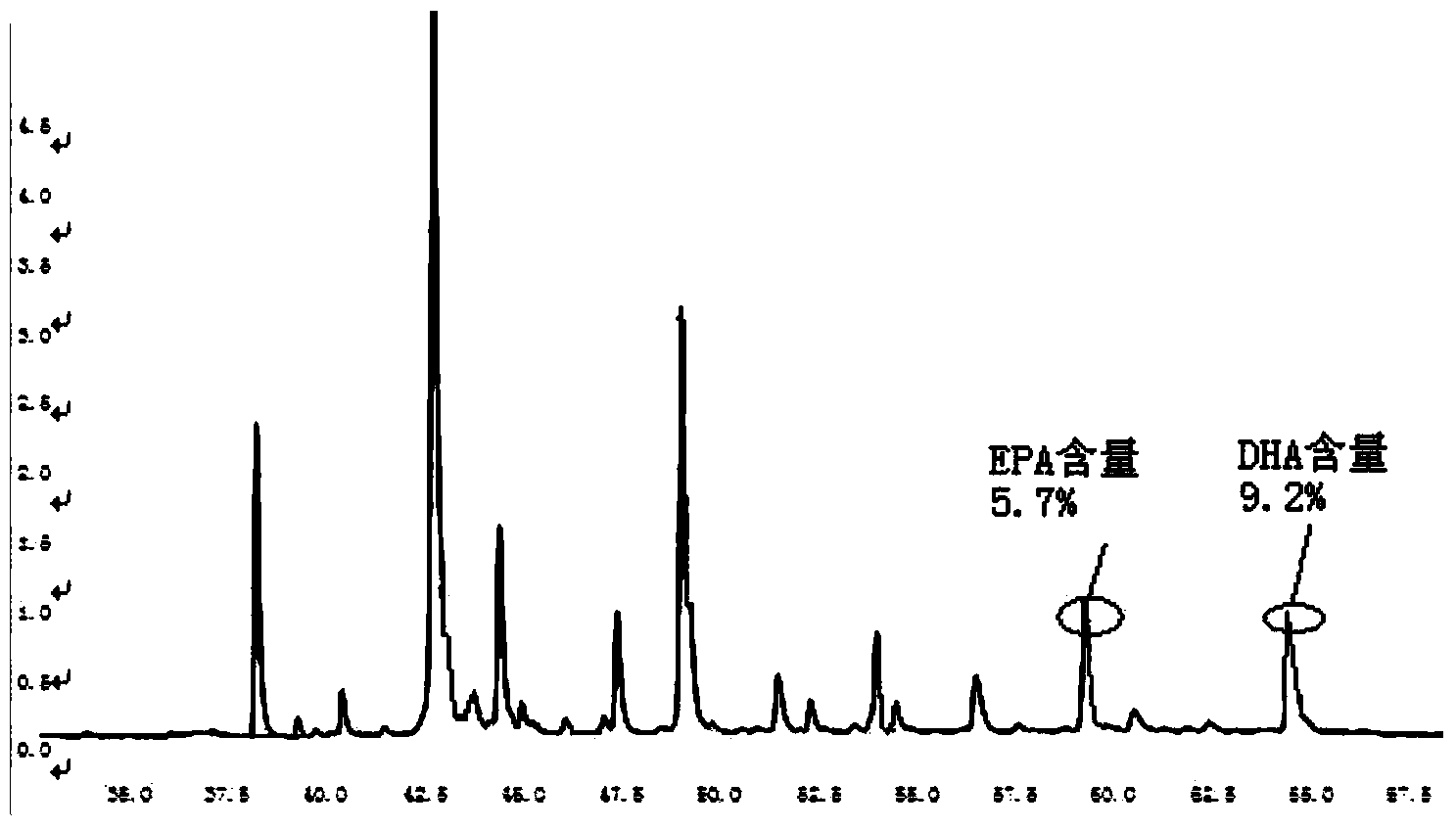

[0030] After degumming, deacidification, decolorization and deodorization, the refined deep-sea fish oil with 18% EPA and DHA content is charged into the hydrogenation reactor, and 0.3% nickel catalyst is added. The reaction temperature is 160℃, the reaction pressure is 0.2MPa and 500r. The reaction was carried out for 30 minutes at a stirring rate of 1 / min to obtain lightly hydrogenated deep-sea fish oil; after the reaction, the lightly hydrogenated fish oil was decolorized at 110°C for 30 minutes by removing the catalyst and 3% by mass of activated clay, and molecular distillation was deodorized. The fish oil product is completely odorless, and the content of EPA and DHA is determined to be 15%, see figure 2 .

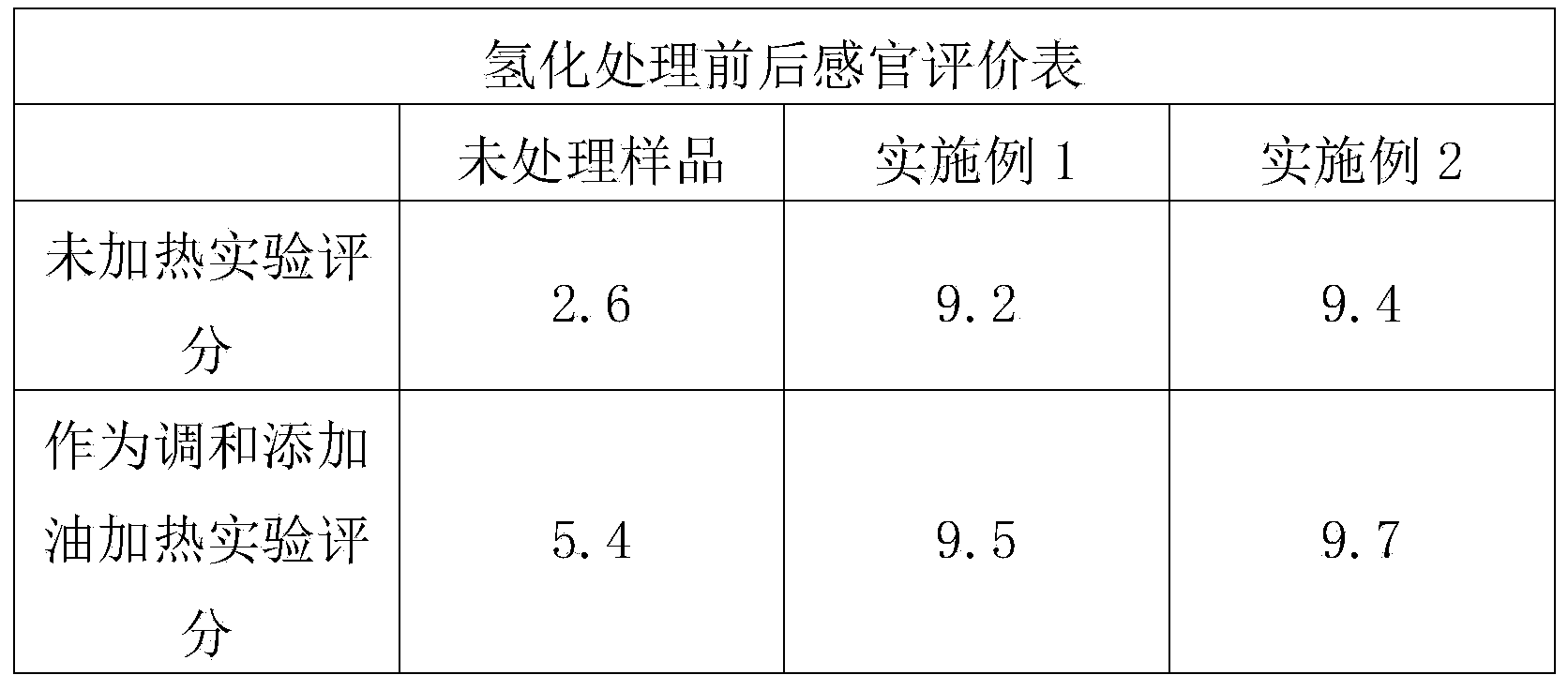

[0031] Sensory evaluation: The prepared deep-sea fish oil was evaluated for fishy odor according to the scoring standard in Table 1. Two control groups were set up, one was the deep-sea fish oil treated according to the present invention, and the other was not treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com