Roofing system and method

A technology for roof components and roof structures, applied to roofs, roof coverings, roofs using tiles/slate tiles, etc., can solve the problems of increasing the cost and weight of slate roofs, and achieve good protection, durable attachment, and easy repairs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

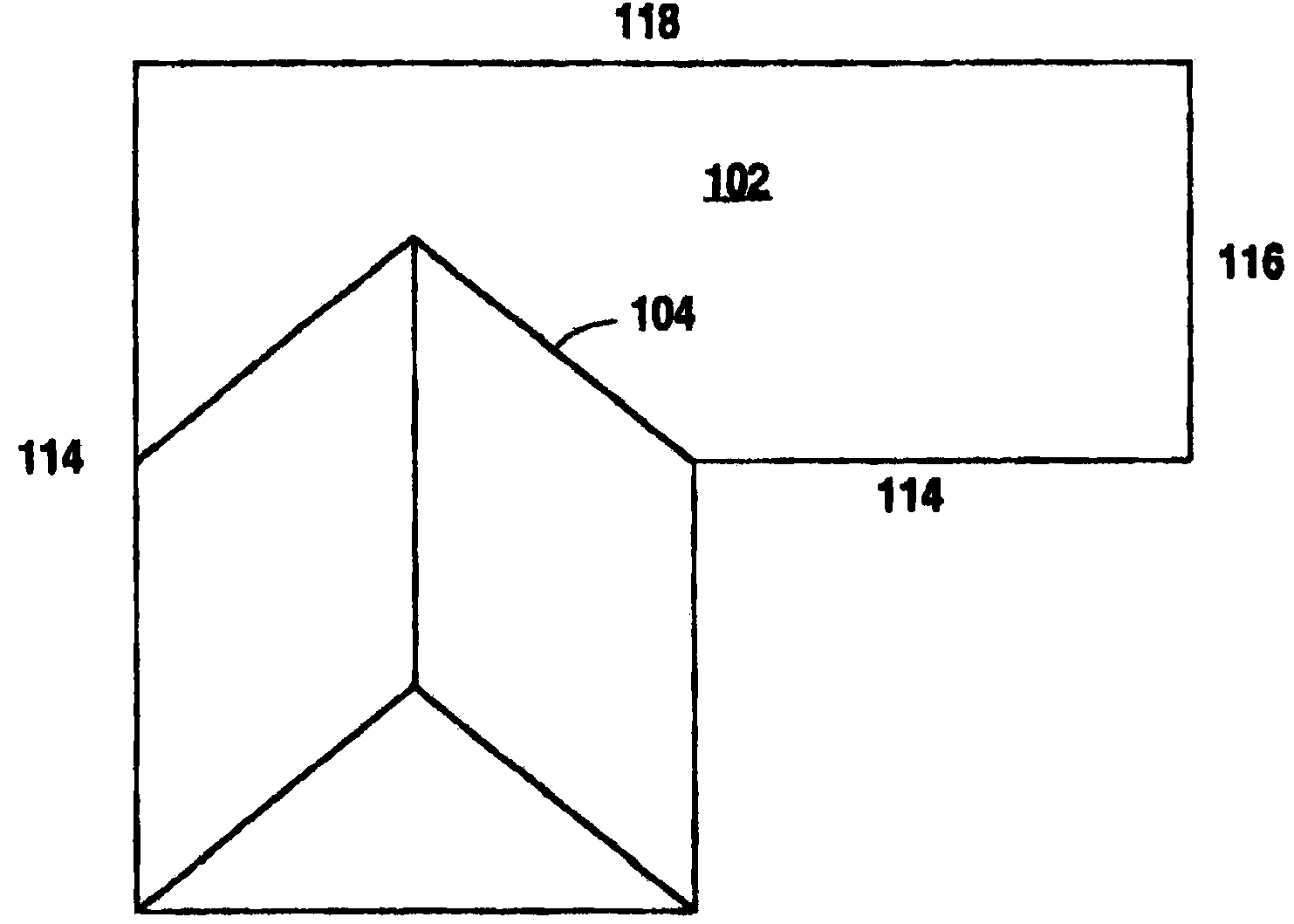

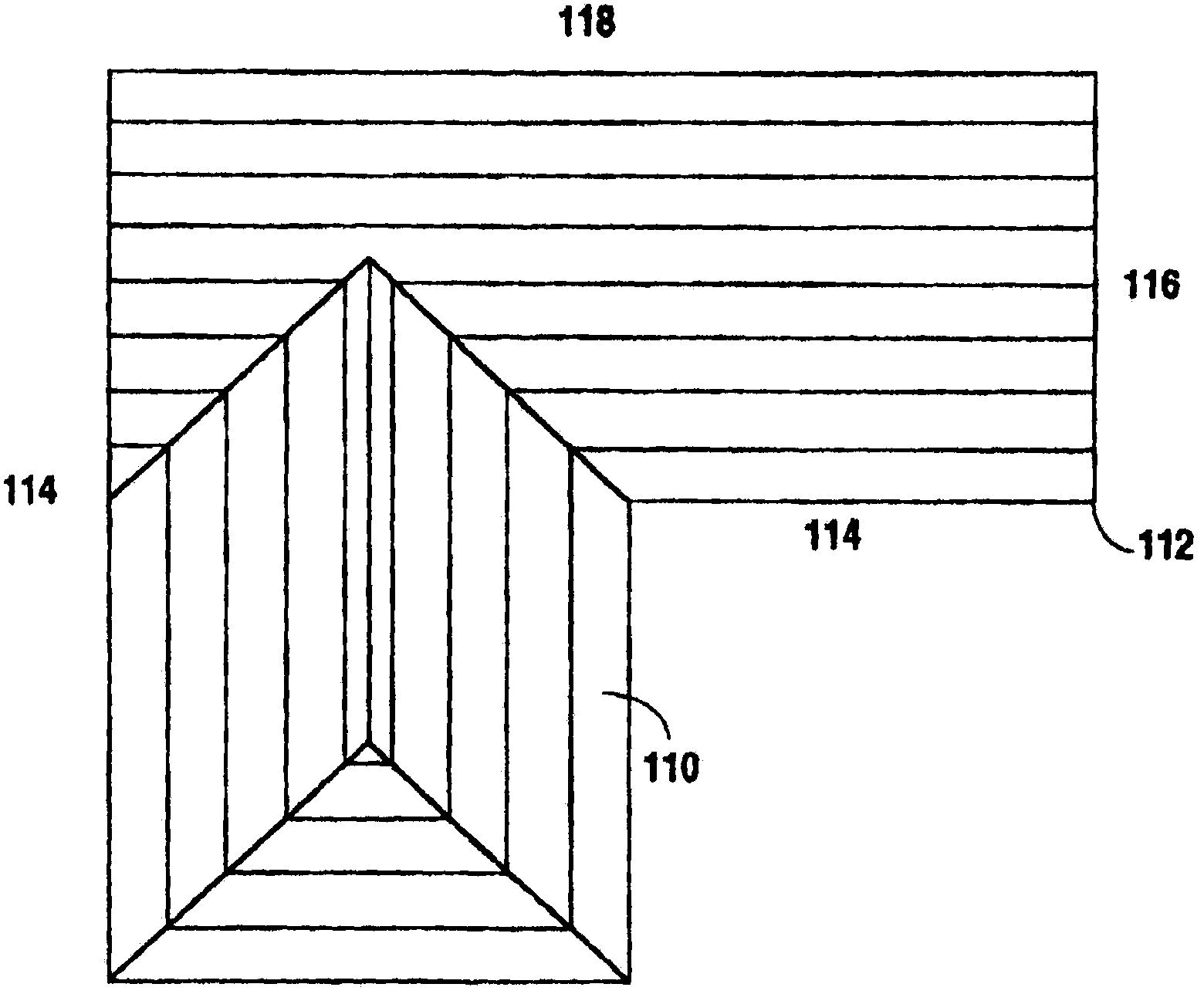

[0049] in figure 1 In, a top view of the roof panel 102 is shown. In the method herein, the initial step is to inspect and prepare the roof slab 102. In one embodiment, the roof slab 102 has a gutter 104, an eave 114, a gable / cantilever 116, and a ridge 118. In this exemplary roof panel 102 inspection step, the existing roof covering (sheathing) is inspected for structural integrity. The roof panel 102 should preferably be plywood with a minimum of 15 / 32 inches, or oriented fiberboard (OSB) approved by law. All the nails of the roof slab 102 should be advanced to be flush with the roof slab 102. The roof slab 102 should be inspected for protrusions that may damage the felt backing 110 (see image 3 ).

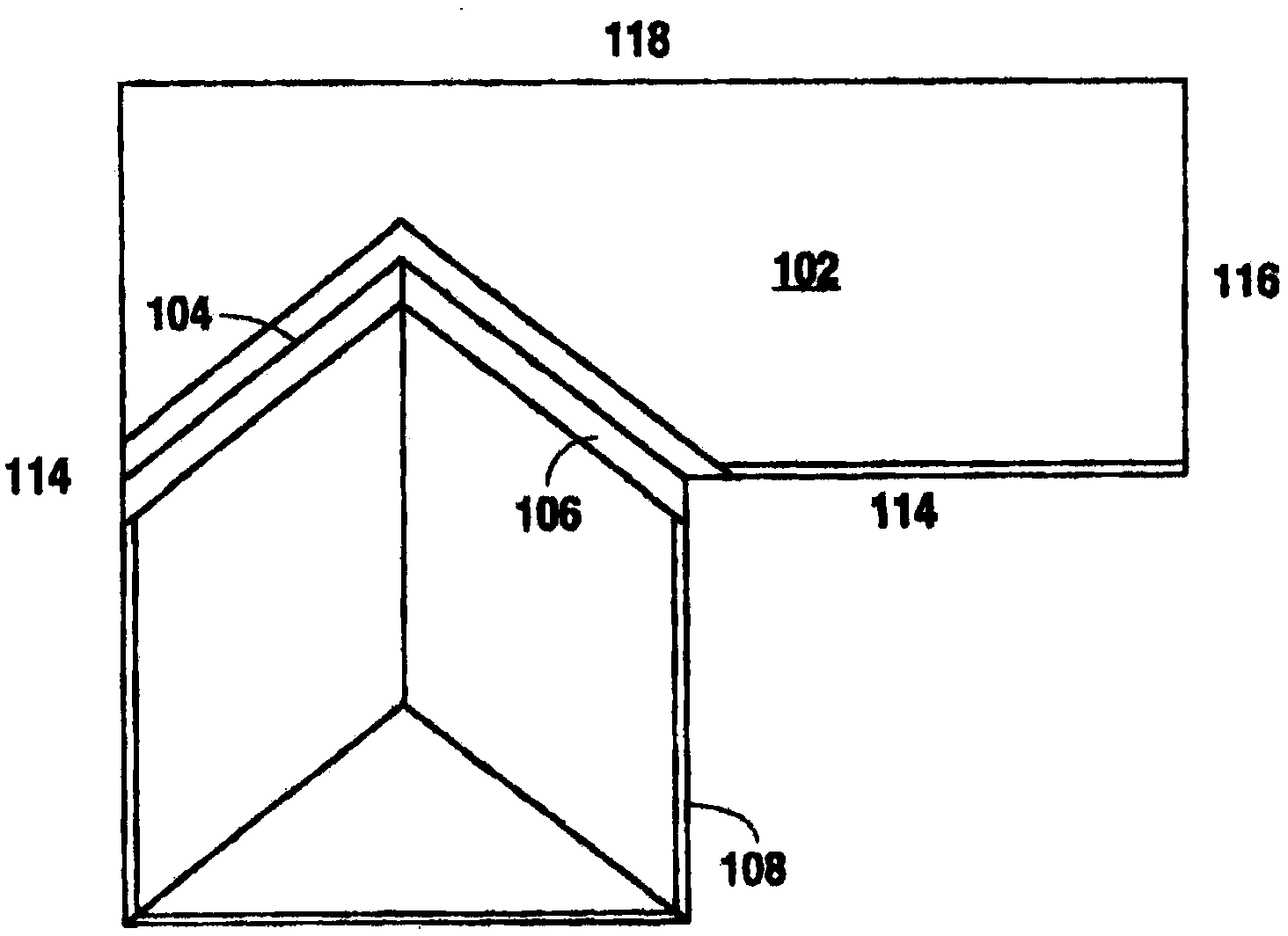

[0050] figure 2 It is a top view of the roof slab 102 illustrating the preparation of the gutter 104 and the installation of the edge 108 of the drip channel. In this step of the method herein, the user installs the peel and stick film 106 in the gutter 104 while overlapping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com