Guiding buffering anti-explosion device for vertical air shaft

A technology of explosion-proof devices and vertical air shafts, which is applied in mining devices, ventilation of mines/tunnels, mining equipment, etc., can solve the problems of low anti-explosion ability and difficult reset of explosion-proof doors, and achieve the goal of improving reliability and anti-explosion ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

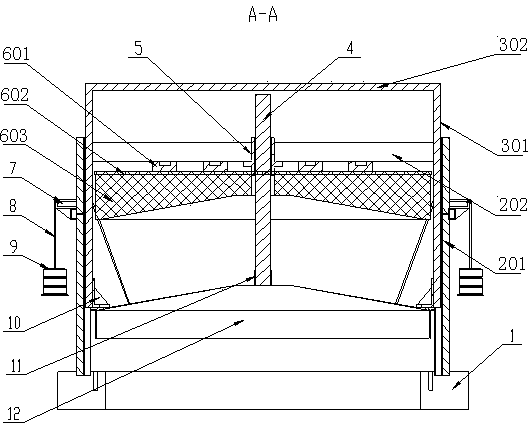

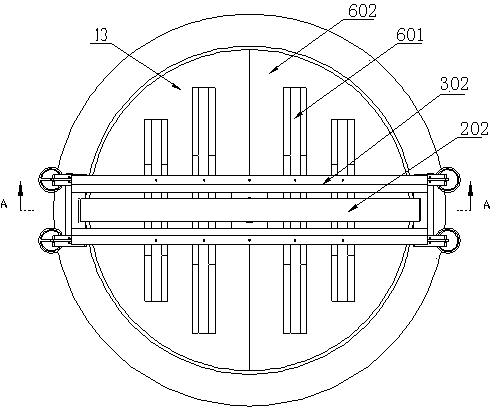

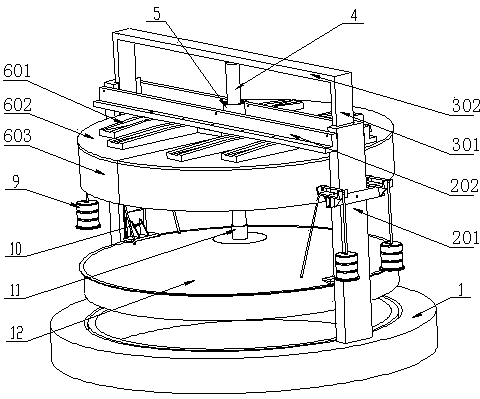

[0042] The pulley frame 7, the wire rope 8 and the counterweight 9 constitute a counterweight mechanism. There are two implementations of the counterweight mechanism. The first embodiment: the pulley frame is fixed on the outer frame column 202; the second embodiment: the current blast door counterweight setting method is used, and 3-4 groups of independent counterweight mechanisms are set.

[0043] The present invention makes full use of the existing explosion-proof door facilities, and is equipped with rigid guiding restraint and buffer energy absorption devices to improve the reliability and anti-explosion ability of the explosion-proof door. The installation and construction of the inner and outer frames, the buffer umbrella, and the counterweight of the present invention have minimal impact on the normal ventilation of the mine, and is beneficial to the implementation of the ventilation shaft explosion-proof door in the production mine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com