Adjusting support for ultrahigh pressure steel pipe assembly

A technology of ultra-high voltage and support, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, workbenches, etc., which can solve problems such as inconvenient operation, low efficiency, and limited steel pipe support, and achieve convenient assembly, strong practicability, The effect of overall ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] The present invention will be described in detail below in combination with specific embodiments and illustrations. This specific embodiment only serves as an introduction, and does not represent the specific protection scope of the present invention.

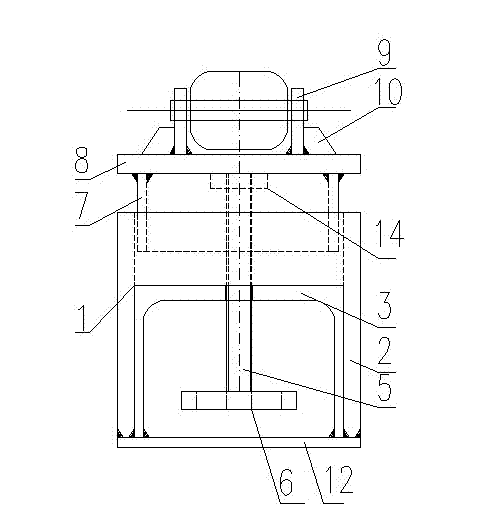

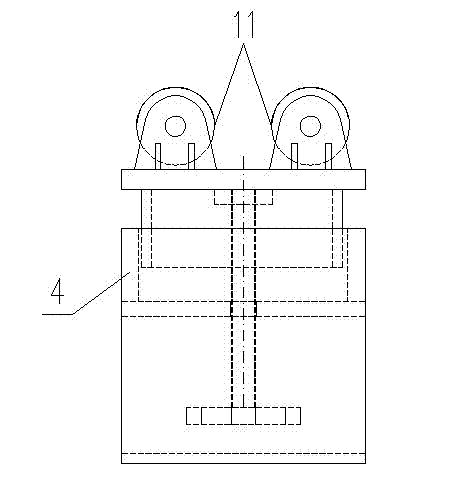

[0015] Weld two support vertical plates 2 at the two ends of square bottom plate 12, measure in support vertical plate 2 and fix an inverted U-shaped support inner rib plate 3, a threaded hole is set on the plane of inner rib plate 3, screw thread It is a trapezoidal thread, mainly used to transmit torque. The height of the above-mentioned inner rib plate 3 should be less than the height of the vertical plate 2. The inner rib plate 3 mainly plays the role of reinforcing the support vertical plate 2 and supporting the threaded hole to transmit torque; one end of the threaded rod 5 that will be used in conjunction with the above-mentioned threaded hole Fix a pressure bearing 14, then install the threaded rod 5 in the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com