Method for measuring electric energy loss of high-energy-consumption smelting system

A technology of power loss and measurement method, applied in the field of detection, can solve problems such as the failure to meet the power loss measurement requirements of high-energy-consuming equipment, and achieve the effect of high market promotion and application value and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

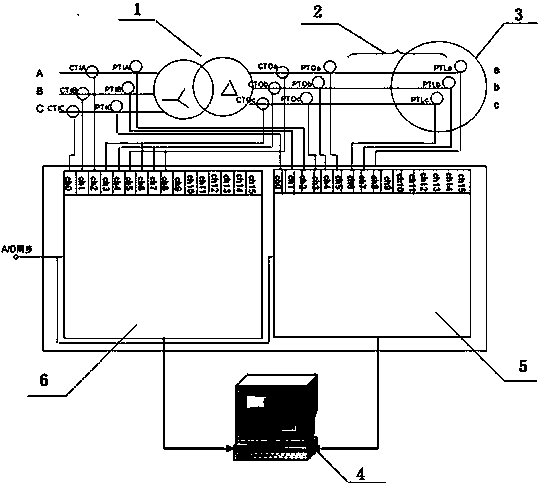

[0021] Below in conjunction with accompanying drawing, the present invention will be further described:

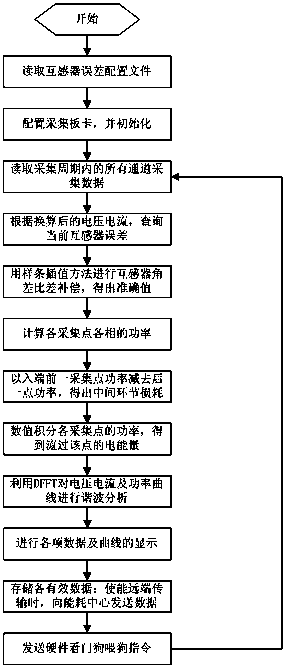

[0022] A method for measuring electric energy loss in a high-energy smelting system, the steps of which are as follows:

[0023] a. Select and install sensors: use voltage transformer PT to sense and collect the voltage signal on the high voltage side of the transformer; use current transformer CT to collect the current signal on the high voltage side of the transformer; Voltage signal; high-current electronic current transformer is used to collect high-current signals on the low-voltage side of the transformer and the short-circuit side;

[0024] b. Determine the sampling period: determine the sampling period through harmonic analysis requirements, online data spectrum analysis, and fast Fourier transform; send the sampling period signal to the A / D conversion module controller;

[0025] c. Sampling: Under the control of the A / D conversion module controller, analog / digita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com