Processing machine of light guide plate

A technology of light guide plate and processing machine, applied in the field of light guide plate, which can solve the problems of product yield impact and influence on the efficiency of dot processing, and achieve the effects of ensuring efficiency, improving yield, and avoiding fingerprint dirt and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] As mentioned in the background art, using the existing light guide plate processing machine to process the dots of the light guide plate requires manual shifting of multiple light guide plates, which not only affects the processing efficiency, but also affects the yield of the product. The inventor found that the main reason for this defect is that after the processing is completed, the light guide plate needs to be taken manually, which not only affects the processing efficiency, but also causes fingerprints to appear dirty due to the contact with the processed light guide plate. And scratches, etc., reduce the yield of the product.

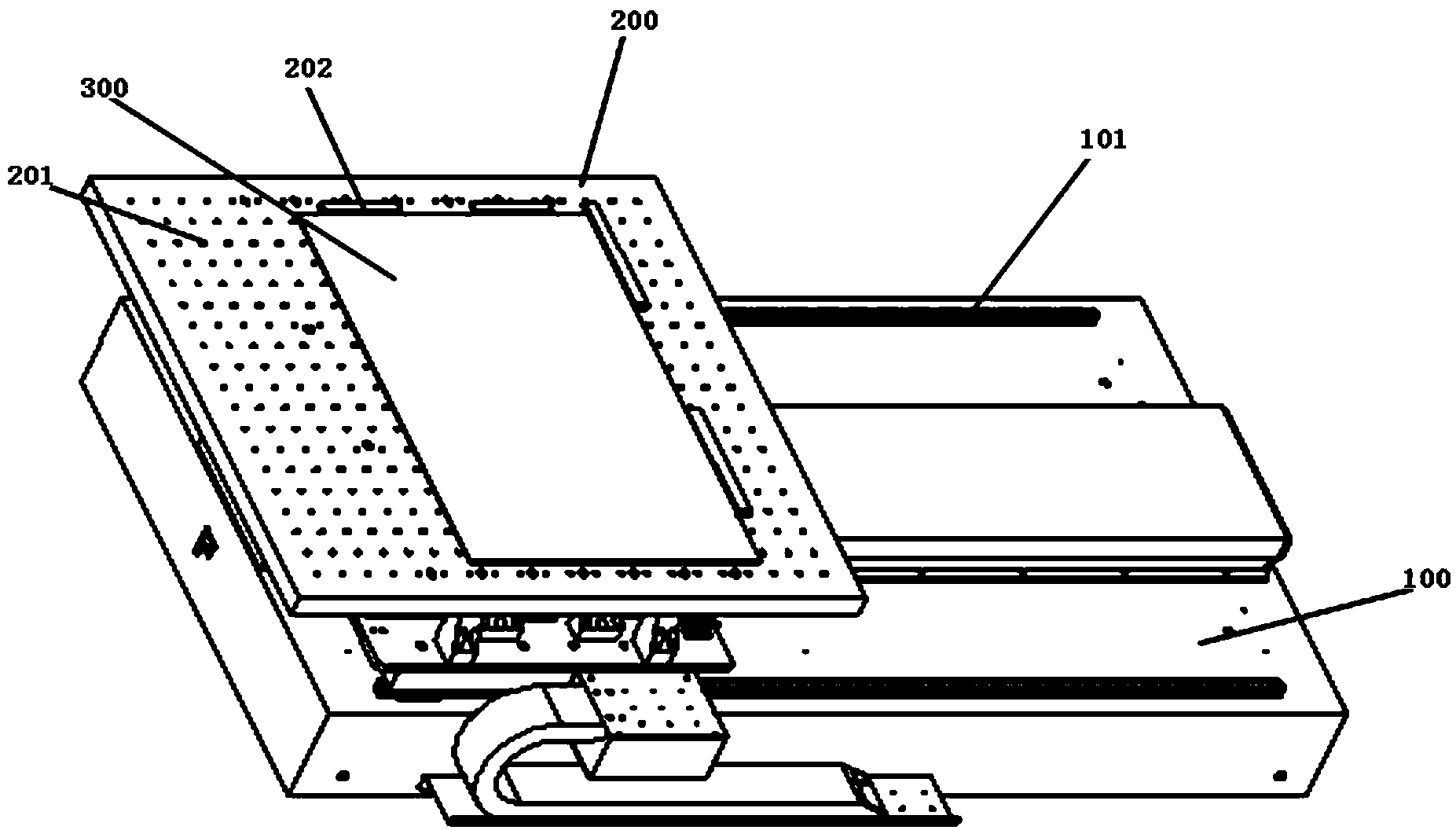

[0019] refer to figure 1 As shown, it is a partial structural schematic diagram of an existing light guide plate processing machine, including a sliding platform 100 and a processing platform 200, and a slide rail 101 is arranged between the sliding platform 100 and the processing platform 200, so that the processing platform 200 can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com