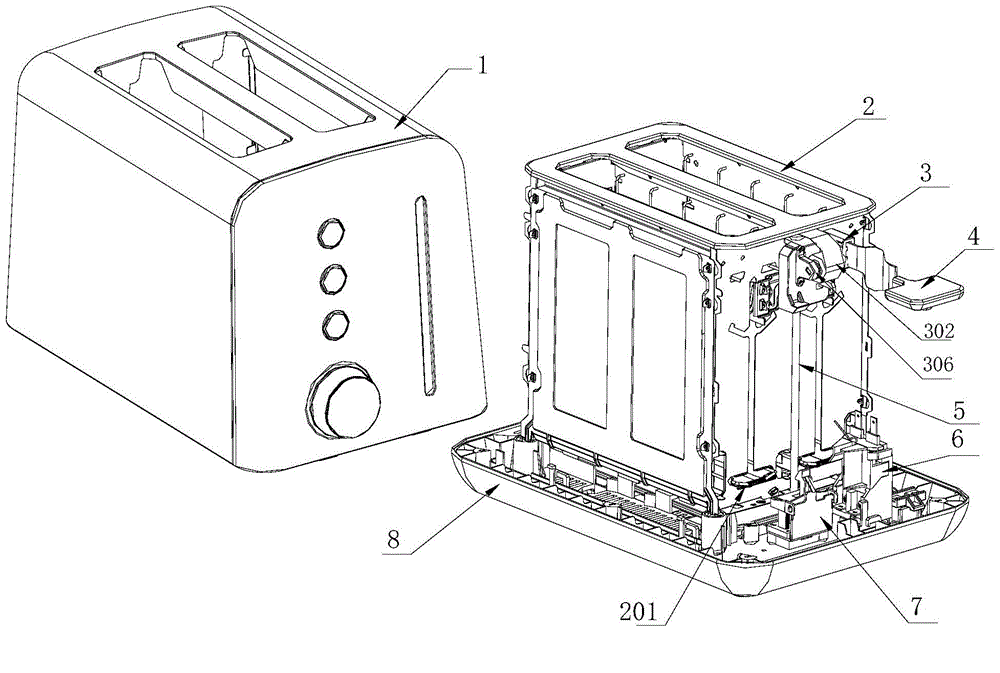

Clockwork spring driving slide block lifting mechanism and toaster thereof

A technology of a clockwork drive and a lifting mechanism, which is applied to household appliances, toasting devices, applications, etc., can solve the problems of false bread models rising in place, complicated assembly, and high requirements for parts coordination, and achieves balanced strength, simple structure, and coordination requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is further described.

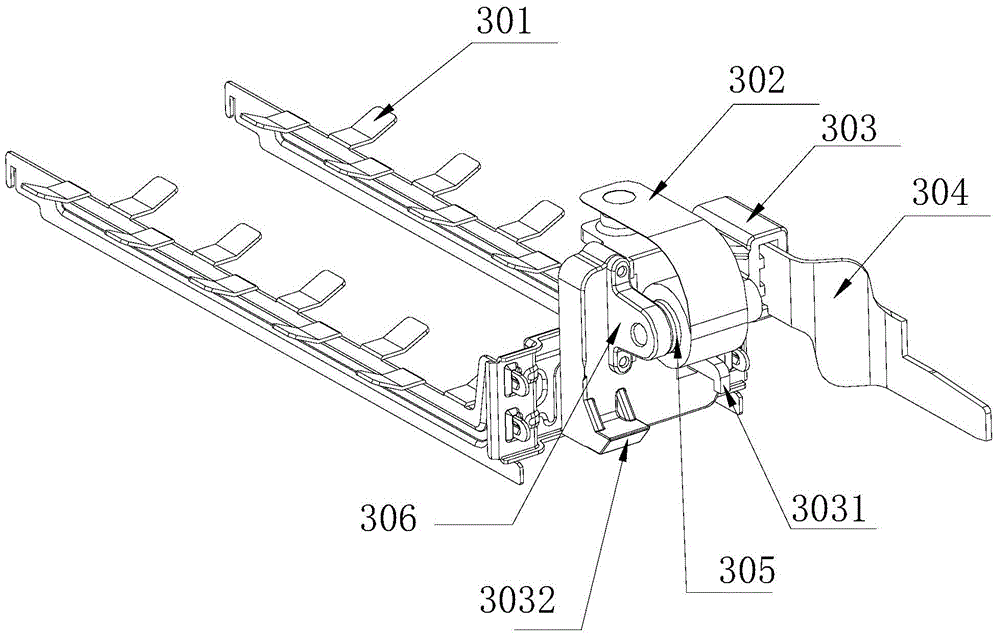

[0026] Such as figure 2 , Figure 4 As shown, a spring-driven carriage lifting mechanism includes a bread carriage 301, a carriage 303, and a handle 304. The bread carriage 301 is installed on the inner surface of the carriage 303, and the handle 304 is installed on the outer surface of the carriage 303. Slide frame 303 is installed on the side surface of movement assembly 2, and slide frame 303 can move up and down in movement assembly 2, and spring 302, rotating shaft 305 and rotating shaft holder 306 are set on slide frame 303, and the outer surface of slide frame 303 The side is fixed with a rotating shaft fixing seat 306, and the rotating shaft fixing seat 306 is provided with a rotating shaft 305. On, the outer end of spring 302 is fixed on the upper part of movement assembly 2 .

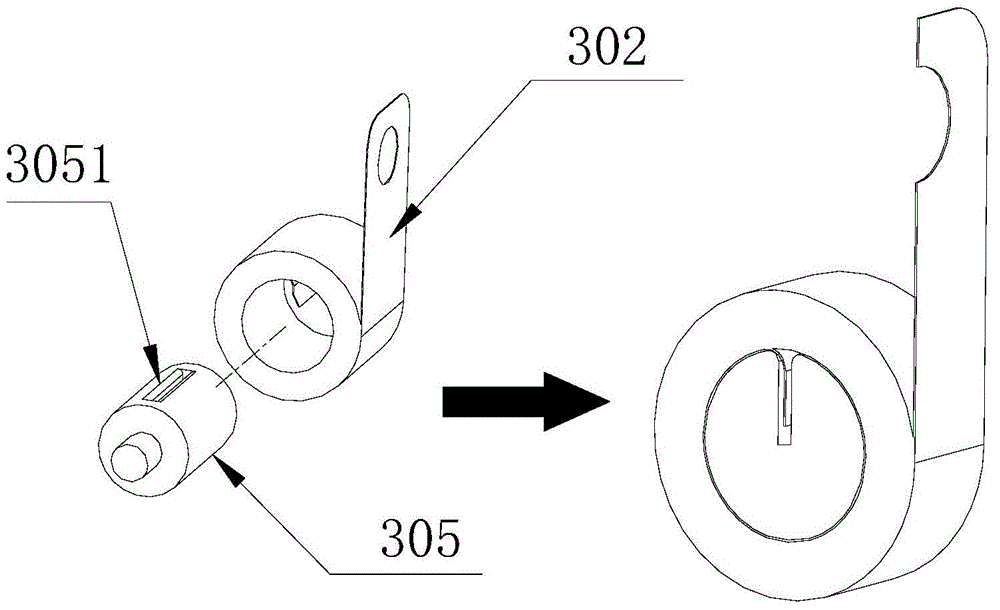

[0027] Such as image 3 As shown, the middle part of the rotating shaft 305 is provided with a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com